CSSDS Medical Devices Suppliers

The CSSD Equipment is an important department in the hospital responsible for the recovery, cleaning, disinfection, sterilization, and supply of sterile items for reusable medical devices, instruments, and items.

In the purification area, the main task of CSSD Equipment is to remove organic matter, inorganic matter, and microorganisms from the instruments to ensure the cleanliness of the instrument surface.

The clean area is the area in the CSSD Equipment where the decontaminated instruments are inspected, assembled, packaged, and sterilized.

The item storage area is the last key area of CSSD Equipment, which is used to store, keep, and issue sterile items.

With a building area of 20,310 square metres, the company has a class 100,000 purified production workshop, a class 10,000 microbiology testing room, a local class 100 physical and chemical laboratory, and a standardised storage system for raw materials and finished products.

Since the initial batch of products were launched in 2013, Eray has continuously enriched its product categories. Our products have covered protective masks, nursing consumables, sensory control consumables, surgical instruments, providing safe, efficient and environmentally friendly disposable medical solutions for medical institutions worldwide.

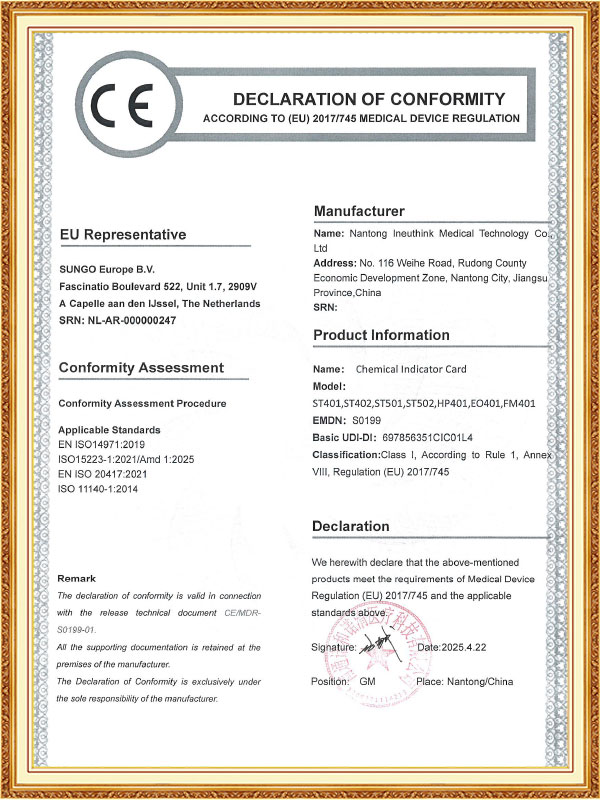

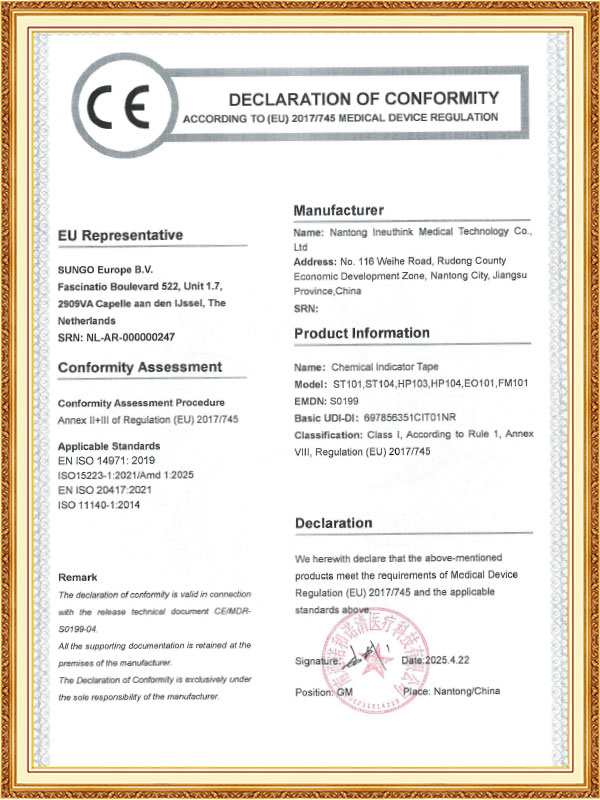

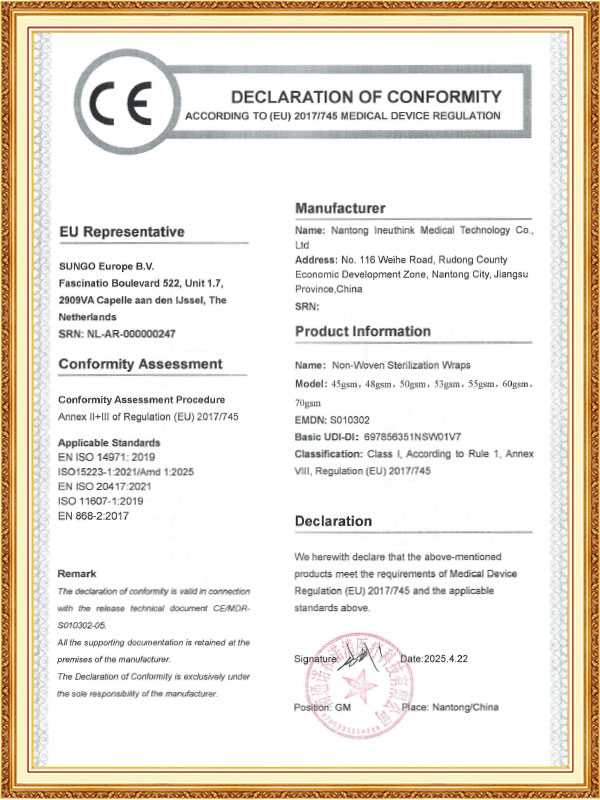

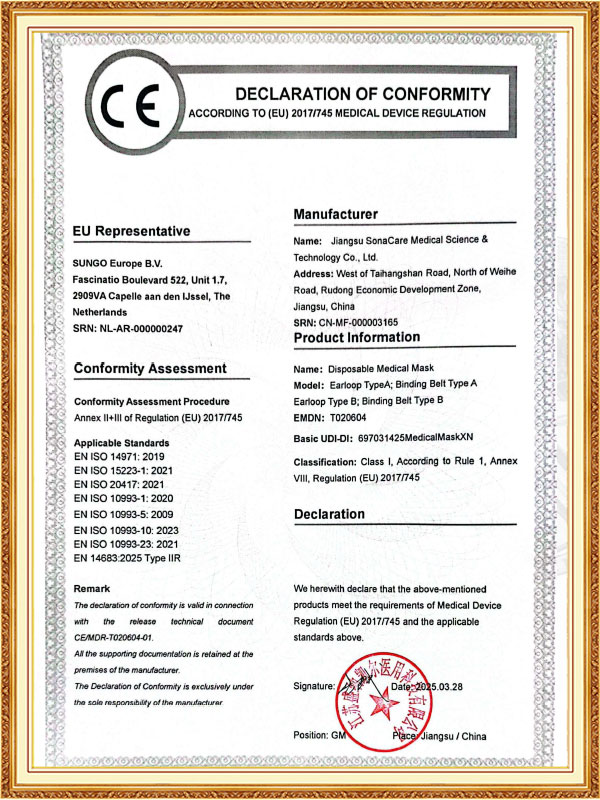

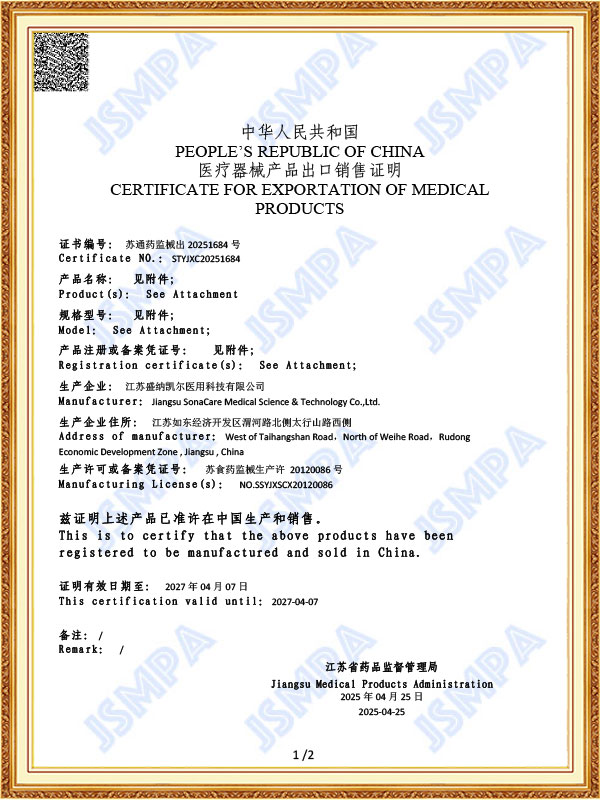

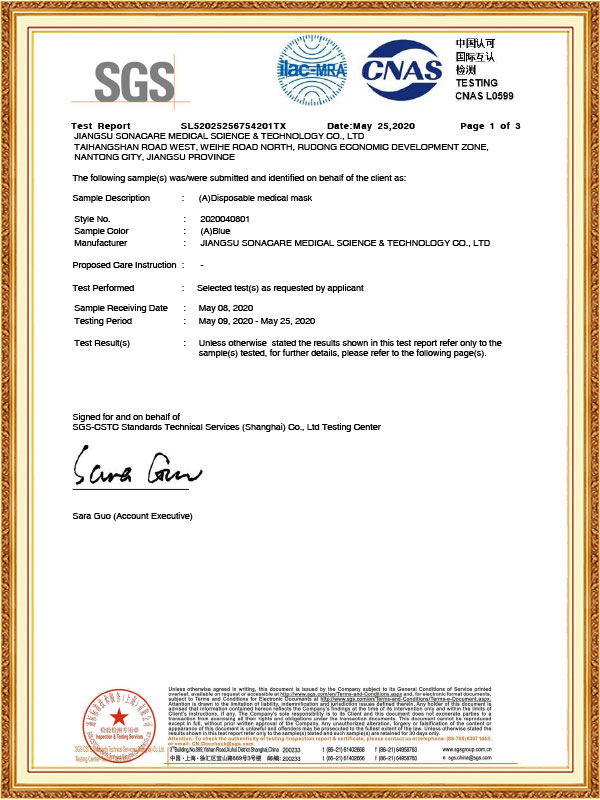

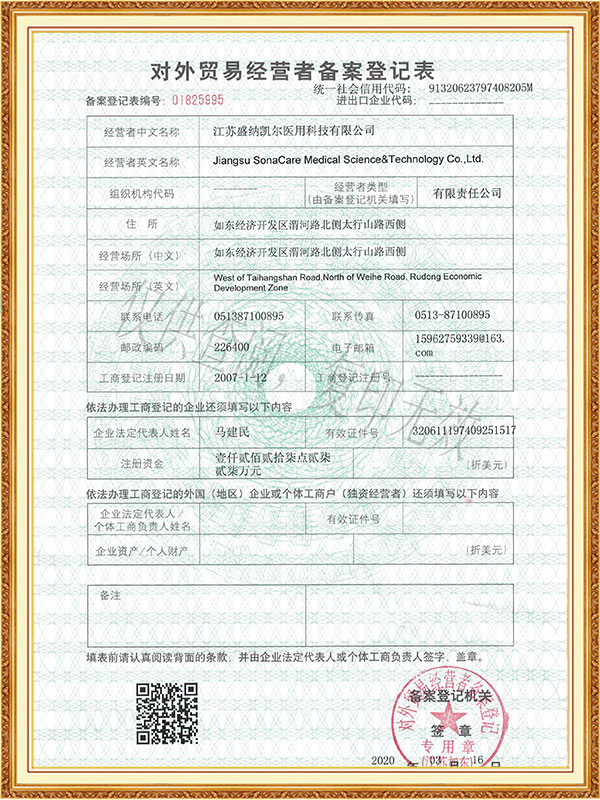

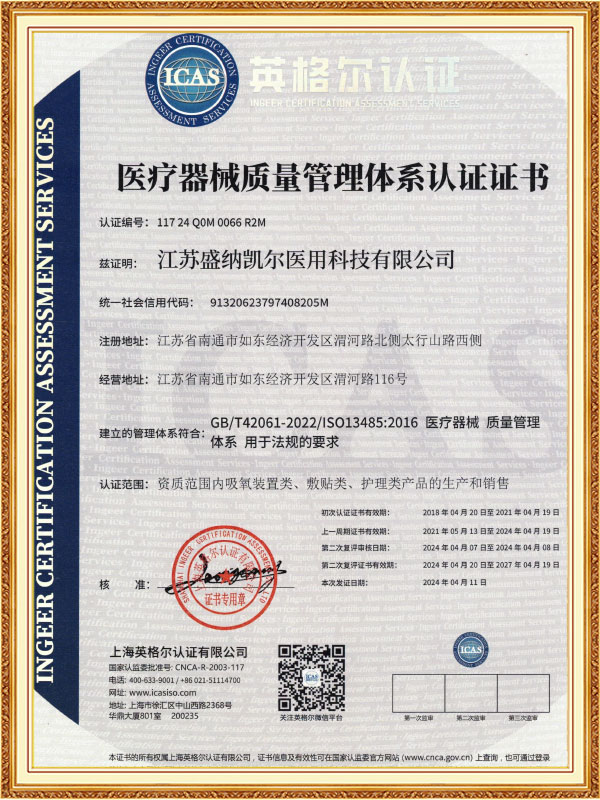

As a professional OEM CSSDS Medical Devices Suppliers and ODM CSSD furniture and small equipment Factory, The company has passed ISO 13485 and other quality system certifications, and some of its products have obtained CE certification and FDA filing permits, and has established long-term cooperative relationships with many domestic and foreign medical institutions and distributors.

-

Feb 27. 2026

Can Optical Trocars Reduce the Risk of Organ Injury?Optical Trocars Significantly Reduce Organ Injury Risk Yes, optical trocars can significantly reduce the risk of organ injury during laparoscopic surgery by allowing surgeons to visualize tissue layers in real time as the instrument passes through the abdominal wall. Unlike blin...

Read More -

Feb 20. 2026

What is an Optical Trocar and Why is it Essential in Medical Procedures?What is an Optical Trocar and Why is it Essential in Medical Procedures? An optical trocar is a specialized surgical instrument used primarily in minimally invasive procedures. It combines the functions of a trocar and a visual scope, allowing surgeons to create an access point ...

Read More -

Feb 13. 2026

What Are the Common Problems With Medical Trocars and How to Avoid Them?What Are the Most Common Problems With Medical Trocars? The most common problems with medical trocars include insertion injuries, gas leakage, dull blades, instability, and contamination risks. These issues can compromise surgical safety, increase operating time, and raise posto...

Read More

The Equipment Department of the Center for Sterilization and Supply (CSSD) plays a crucial role in the hospital's infection control system. As the core department responsible for the comprehensive management of reusable medical devices within the hospital, the CSSD ensures the safe and reliable sterility of every medical device through scientific zoning and advanced equipment configuration, providing a solid foundation for clinical diagnosis and treatment.

The cleanroom is the starting point for the CSSD's Equipment Department, equipped with fully automatic washer-disinfectors, ultrasonic cleaning machines, and other specialized equipment. Upon arrival, used medical devices undergo rigorous decontamination treatment here. The multi-tank cleaning system uses a standardized process including pre-wash, enzyme wash, and rinse, combined with specialized cleaning agents, to effectively remove organic matter such as blood and tissue residue from the device surfaces and lumen. The dual effects of a high-temperature water bath and chemical disinfection eliminate most pathogenic microorganisms. Specially designed instrument cleaning baskets and lumen brushes ensure thorough cleaning of even the most complex instruments. The negative pressure environment and air purification system in the cleanroom effectively prevent the spread of contaminants, protecting staff safety.

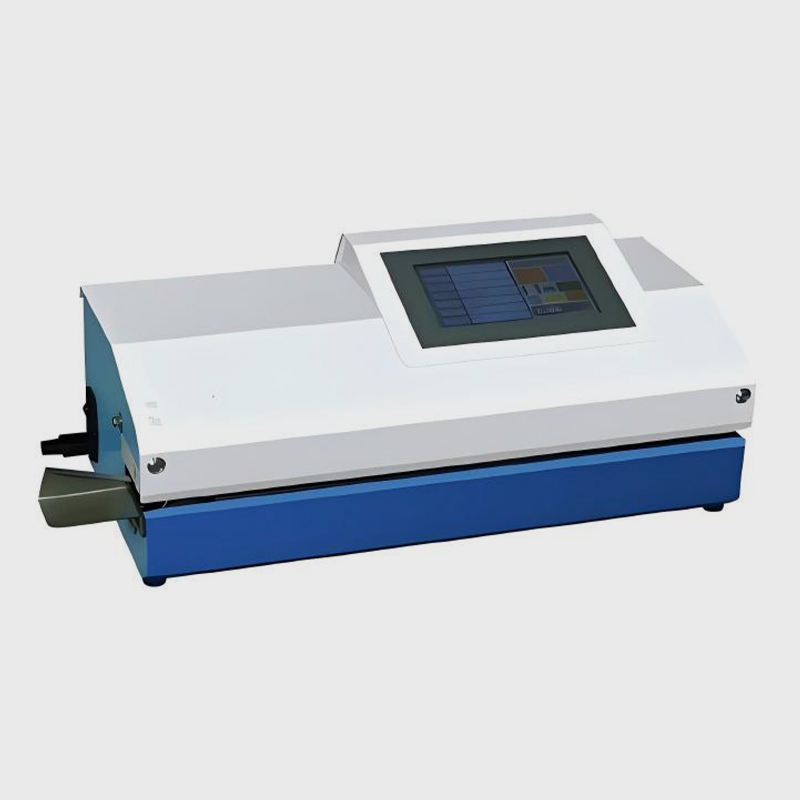

Once purified, instruments enter the cleanroom, where they undergo even more meticulous handling. Staff conduct visual inspections of instruments at dedicated workbenches, using lighted magnifying glasses to ensure the absence of any residue. The precision instrument assembly table is equipped with a torque adjustment device to ensure accurate assembly. ISO-compliant medical packaging materials are used, with appropriate packaging methods selected based on the instrument's characteristics, such as rigid containers, paper-plastic bags, or sterilization pouches. Advanced sealing equipment ensures a tight seal, and each package is labeled with a chemical indicator label and a traceability barcode. A HEPA filtration system in this area maintains a positive pressure environment, strictly controlling temperature and humidity within specified ranges, providing ideal conditions for final preparations before sterilization.

After sterilization, sterile items are stored in a storage area, which utilizes laminar flow purification technology and serves as the hospital's "sterile item bank." The intelligent storage system categorizes items by type and frequency of use. High-value consumables are managed using RFID technology, while common items are tracked using barcodes. An environmental monitoring system records parameters such as temperature, humidity, and pressure differential in real time, providing immediate alarms if any exceedances occur. Fully automated dispensing equipment is integrated with the hospital's HIS system, enabling an electronic process for application, approval, and dispensing. Specially designed transport vehicles equipped with ultraviolet disinfection ensure the safety of sterile items during transport. Regular sampling, testing, and inventory checks of sterile items provide dual assurance for clinical use.

The modern CSSD Equipment Department has evolved into a highly intelligent and specialized department. From contamination control during instrument recycling, to quality assurance during cleaning and disinfection, to parameter verification during sterilization, and finally to meticulous management of sterile storage, every step embodies the principles of precision medicine. By incorporating IoT technology, the CSSD achieves traceability throughout the entire instrument lifecycle. The use of automated equipment significantly improves work efficiency, and the establishment of standardized operating procedures ensures consistent work quality. These advancements enable the CSSD Equipment Department to not only meet daily supply needs but also demonstrate strong emergency response capabilities during public health emergencies, making it an indispensable component of the hospital's infection control system.

The CSSD Equipment Department plays an irreplaceable role in infection control. Through rigorous quality monitoring procedures such as daily B-D testing and regular verification of biological indicators, they effectively mitigate the risk of nosocomial infections caused by equipment contamination. The department demonstrates rapid response capabilities in the face of urgent clinical needs. Its 24-hour on-call system and backup equipment ensure that emergency equipment can be serviced within half an hour at any time. In terms of cost control, they optimize equipment usage and standardize maintenance procedures, extending the lifespan of expensive precision equipment while reducing hospital operating costs. The CSSD Equipment Department also plays a crucial role in scientific research and talent development. Based on analysis of equipment operational data, they provide professional advice for hospital procurement decisions. They continuously enhance the team's capabilities by organizing various professional technical training and certification courses. Regarding compliance management, they ensure that all operational procedures strictly adhere to the latest regulatory requirements and develop comprehensive emergency response plans to address various emergencies. The CSSD Equipment Department is like the "invisible guardian" of medical institutions, silently safeguarding the health and safety of every patient with professional technology and rigorous management, and is a key support for the efficient operation of modern hospitals.

English

English Español

Español Français

Français

CONTACT US

CONTACT US