What Are the Common Problems With Medical Trocars and How to Avoid Them?

Content

- 1 What Are the Most Common Problems With Medical Trocars?

- 2 Insertion Injuries and Tissue Damage

- 3 Gas Leakage and Poor Sealing Performance

- 4 Dull Blades and Reduced Cutting Efficiency

- 5 Trocar Instability During Surgery

- 6 Contamination and Infection Risks

- 7 How to Choose High-Quality Medical Trocars

- 8 FAQ About Medical Trocars

What Are the Most Common Problems With Medical Trocars?

The most common problems with medical trocars include insertion injuries, gas leakage, dull blades, instability, and contamination risks. These issues can compromise surgical safety, increase operating time, and raise postoperative complication rates. Understanding these problems and implementing preventive measures is essential for hospitals, surgeons, and medical device purchasers.

Medical trocars are widely used in laparoscopic and minimally invasive surgeries, with global laparoscopic procedure volumes exceeding 15 million operations annually. Even a small failure rate can affect thousands of patients, making trocar quality and proper usage critically important.

Insertion Injuries and Tissue Damage

One of the most serious trocar-related problems is accidental injury during insertion. Sharp obturators may damage blood vessels, bowel tissue, or internal organs if improperly used.

Why This Happens

- Excessive insertion force

- Incorrect insertion angle

- Low-quality blade manufacturing

How to Avoid It

Using safety trocars with shielded tips can reduce injury risk by up to 30%. Surgeons should also follow standardized insertion protocols and verify abdominal wall tension before entry.

Gas Leakage and Poor Sealing Performance

Gas leakage is a frequent complaint in laparoscopic procedures. When CO₂ escapes from trocar valves, pneumoperitoneum pressure drops, reducing visibility and surgical efficiency.

| Cause | Impact |

|---|---|

| Worn valve seals | Pressure loss |

| Poor material elasticity | Air leakage |

| Improper instrument size match | Seal failure |

Selecting trocars with double-seal valve systems and medical-grade silicone components can significantly improve airtight performance.

Dull Blades and Reduced Cutting Efficiency

Dull trocar blades increase insertion resistance and may cause excessive tissue trauma. Studies show that poor cutting efficiency can increase insertion force by up to 40%.

Prevention Tips

- Use disposable trocars for consistent sharpness

- Inspect reusable trocars after sterilization cycles

- Choose hardened stainless steel obturators

Trocar Instability During Surgery

Unstable trocars may shift or loosen during instrument manipulation. This can disrupt camera positioning and increase surgeon fatigue.

High-quality trocars use textured sleeves, fixation rings, or balloon anchoring systems that improve stability by up to 25% compared to smooth-surface designs.

Contamination and Infection Risks

Improper sterilization or packaging defects can introduce bacteria into surgical sites. Hospital infection control data indicates that contaminated instruments contribute to 5–7% of postoperative infections.

Best Practices

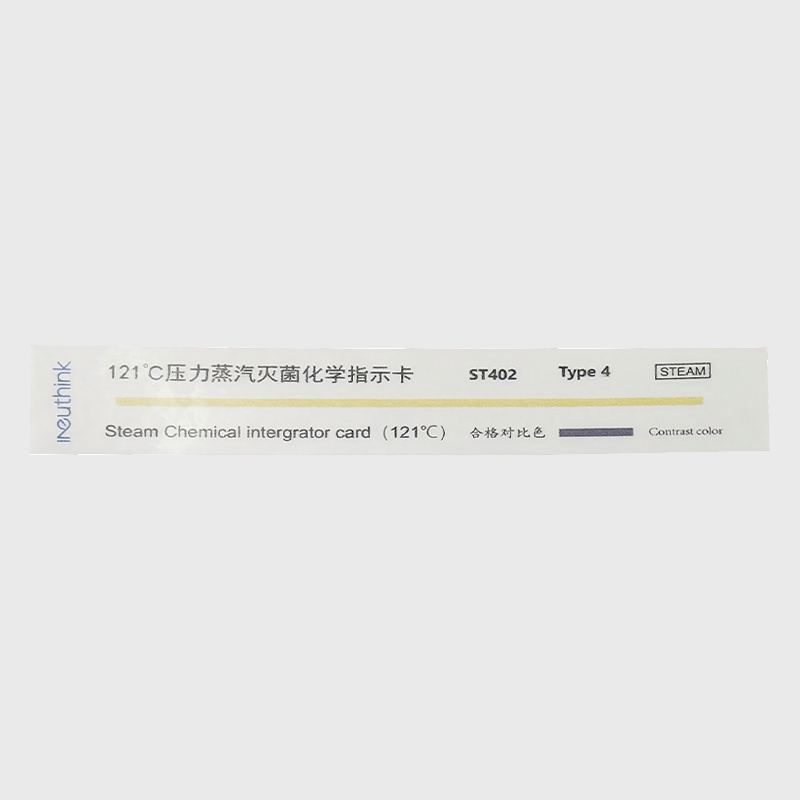

- Use ISO-certified sterile packaging

- Verify seal integrity before surgery

- Follow validated sterilization protocols

How to Choose High-Quality Medical Trocars

Choosing the right trocar supplier is just as important as surgical technique. Hospitals should prioritize products that meet CE, ISO 13485, and MDR compliance standards.

| Feature | Importance |

|---|---|

| Valve sealing system | Gas retention |

| Blade material | Insertion safety |

| Sterile packaging | Infection control |

FAQ About Medical Trocars

Are disposable trocars safer than reusable ones?

Disposable trocars reduce cross-contamination risks and ensure consistent blade sharpness, making them safer for high-volume surgical environments.

How often should reusable trocars be replaced?

Most manufacturers recommend replacement after 80–100 sterilization cycles, depending on usage conditions.

What trocar size is most commonly used?

The most common sizes are 5mm, 10mm, and 12mm, covering the majority of laparoscopic procedures.

Can poor-quality trocars increase surgery time?

Yes. Gas leakage, instability, and dull blades can extend procedure time by 10–20%, reducing operating room efficiency.

English

English Español

Español Français

Français

CONTACT US

CONTACT US