WHAT WE DO

We prioritize the well-being and comfort of our patients,offering

personalized treatments and a supportive

Medical Device Solutions

Eray has established a comprehensive quality control system that encompasses the entire production process, including testing and traceability, from the ISO Class 8 cleanroom to a partial ISO Class 6 physical and chemical laboratory, ensuring that every customer receives trustworthy products.

Ward Care

We prioritize the well-being and comfort of our patients, offering personalized treatments and a supportive.

Respiratory Therapy

For the ICU, emergency department, and chronic respiratory disease management.

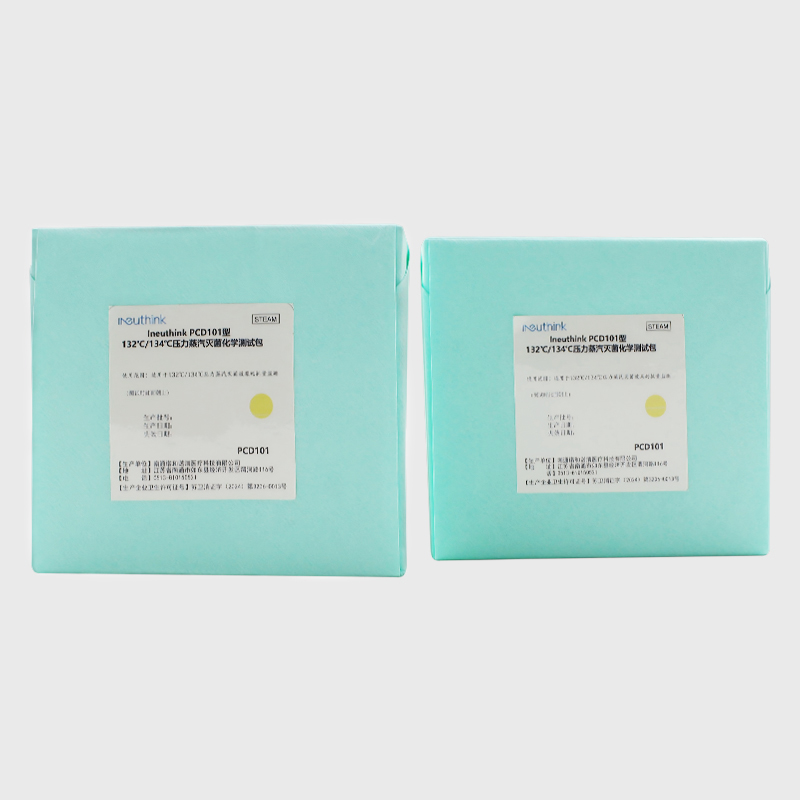

Sterilisation Monitoring

For the central supply room (CSSD), operating theatre instrument sterilisation control, etc.

Minimally Invasive Surgery

For laparoscopy, ligation, anastomosis, and other minimally invasive surgery.

-

0m2

Company Area

-

0

Founded In

-

0

Employees

-

0

Cooperative Customer

ERAY HAS BUILT THE WHOLE PROCESS OF PRODUCTION, TESTING AND TRACEABILITY

Eray Medical Technology (Nantong) Co., LTD., is a medical device manufacturing enterprise

integrating research and development, production, and sales. The company is located in Rudong

Economic Development Zone, adjacent to Shanghai, with convenient transportation, and

developed information. As a professional

VIEW MORE

medical devices manufacturers and medical consumables factory

, The company covers an area of 70 mu, with a construction area of 20310 square meters. It has an ISO Class 8 cleanroom, an ISO Class 7 microbiological laboratory, and a partial ISO Class 6 physical and chemical laboratory.ERAY

TRUSTED AUTHORITATIVE

CERTIFICATE

Eray has passed ISO 13485, CE and other international certifications. We have also obtained FDA registration for some of our products, and have established a complete quality traceability and verification system. We believe that stable and reliable products come from adherence to standards.

WHAT’S NEWS

-

Industry NewsJan 08 ,26

-

Industry NewsJan 01 ,26

-

Industry NewsDec 23 ,25

-

Industry NewsDec 16 ,25

-

Industry NewsDec 09 ,25

-

Industry NewsDec 02 ,25

English

English Español

Español Français

Français

CONTACT US

CONTACT US