What is a CSSD device?

Content

- 1 1.What is a CSSD device?

- 2 2.What are the main categories of CSSD equipment?

- 3 3.How to manage CSSD devices?

- 3.1 (1) Procurement and acceptance management of CSSD equipment

- 3.2 (2). Daily Operation and Management of CSSD Equipment

- 3.3 (3) Maintenance and care management of CSSD equipment

- 3.4 (4) Quality control management of CSSD equipment

- 3.5 (5) Personnel training and management of CSSD equipment

- 3.6 (6) Emergency management of CSSD equipment

- 4 4.What are the common faults of CSSD equipment?

- 5 5.Frequently Asked Questions about CSSD Devices

1.What is a CSSD device?

In medical institutions, the Central Sterile Supply Department (CSSD) is one of the core departments to ensure medical safety. As its core component, CSSD equipment undertakes important tasks such as cleaning, disinfection, sterilization, packaging, storage and distribution of medical devices, which is directly related to surgical safety, infection control and patient health.

(1) The role of CSSD equipment

The main task of CSSD equipment is to ensure that all reusable medical devices are sterile before each use, thereby avoiding cross infection and nosocomial infection. Specifically, CSSD equipment needs to complete the following key links:

Cleaning: Thoroughly remove blood, tissue residues, microorganisms and other contaminants on the surface of the device.

Disinfection: Kill most pathogenic microorganisms through chemical or physical methods.

Sterilization: Use high temperature, chemical gas or plasma technology to completely eliminate all microorganisms, including bacterial spores.

Packaging: Use sterile packaging materials to seal the device to prevent re-contamination after sterilization.

Storage and distribution: Store in a sterile environment and distribute to clinical departments as needed. These links are closely linked, and any problem in any step may lead to sterilization failure. Therefore, CSSD equipment must meet strict industry standards to ensure medical safety.

(2) Working principle of CSSD equipment

The working principle of CSSD equipment varies according to its function.

1). Cleaning equipment

Cleaning is the first step in the CSSD process, usually using a combination of mechanical cleaning and manual cleaning. Mechanical cleaning equipment such as spray-type cleaning and disinfection equipment uses high-pressure water and special cleaning agents to flush the surface of the instrument, while ultrasonic cleaning equipment uses high-frequency sound waves to generate tiny bubbles and remove stubborn stains in the gaps of the instrument through cavitation effect. After cleaning, the instrument needs to be rinsed and dried to prevent residual moisture from affecting the subsequent sterilization effect.

2). Sterilization equipment

Sterilization is the most critical link in CSSD. Common sterilization methods include:

Autoclave: Use high temperature (121°C~134°C) and high-pressure steam to penetrate the instrument to kill all microorganisms. It is suitable for metal instruments, cloth and other high-temperature resistant items. Ethylene oxide sterilization (EO Sterilizer): Sterilizes through chemical vapor permeation. It is suitable for plastics, rubber, and electronic devices that are not heat-resistant, but requires a longer ventilation time to remove residual gases.

Hydrogen peroxide plasma sterilization (H₂O₂ Plasma): Uses plasma to decompose hydrogen peroxide molecules in a low-temperature environment, rapidly killing microorganisms. It is suitable for precision instruments such as endoscopes and electrosurgical units.

3) Packaging Equipment

Sterilized instruments must be sealed to prevent contamination during transportation and storage. Heat sealers are used to seal paper-plastic bags or Tyvek packaging, while reusable sterilization containers provide a more reliable barrier.

4) Storage and Traceability Systems

Modern CSSDs are typically equipped with intelligent storage systems that use barcodes or RFID technology to record the cleaning, sterilization, and use of each instrument, ensuring full traceability. Sterile storage areas must maintain a constant temperature and humidity, and laminar flow purification technology should be used to reduce airborne particulate contamination.

(3) Product features of CSSD equipment

CSSD equipment must meet the requirements of high efficiency, safety and intelligence in design. The main features include: High degree of automation: Most modern cleaning and sterilization equipment adopts PLC control system, which can be pre-programmed to reduce human operation errors. Safe and reliable: Sterilization equipment must have real-time pressure and temperature monitoring functions and automatically terminate operation under abnormal conditions to prevent accidents. Energy saving and environmental protection: Some equipment adopts water circulation system or low energy consumption design to reduce resource waste. Strong compatibility: It can handle instruments of various materials and shapes, such as rigid endoscopes, soft catheters, precision surgical instruments, etc. Comply with international standards: such as ISO 13485 (Medical Device Quality Management System), AAMI (American Association for the Advancement of Medical Instrumentation) standards, etc.

(4) The role of CSSD equipment in the medical system

Reducing the risk of hospital infection: Through strict sterilization processes, surgical infections, catheter-related infections and other problems can be effectively reduced.

Improving medical quality: Sterile instruments are the basis for successful surgery, and the stable operation of CSSD equipment is directly related to patient safety.

Optimizing resource management: The intelligent traceability system can monitor the use of equipment, avoid waste and improve turnover efficiency.

Compliance requirements: Health regulatory authorities in various countries have strict regulations on CSSD, such as China's WS 310 standard, to ensure that medical institutions meet infection control requirements.

2.What are the main categories of CSSD equipment?

As the core department of hospital infection control, the Central Sterile Supply Department (CSSD) is responsible for the cleaning, disinfection, sterilization, packaging, storage and distribution of reusable medical devices throughout the hospital. The quality and performance of CSSD equipment are directly related to medical safety and are the first line of defense against hospital infection.

(1) Cleaning and disinfection equipment

Cleaning and disinfection are the first step in the CSSD workflow, and their purpose is to completely remove organic matter, inorganic matter and microorganisms from medical devices. Modern CSSDs are mainly equipped with the following cleaning and disinfection equipment:

Fully automatic cleaning and disinfecting machine: This is one of the most basic equipment in CSSD. It uses a combination of high-temperature water spray and chemical disinfectants to thoroughly clean and disinfect medical devices. Advanced models have a multi-chamber design and can handle different types of devices at the same time. Its operating temperature is usually controlled between 60-95℃, which can effectively kill common pathogenic microorganisms without causing damage to the devices. The built-in water circulation filtration system of the equipment can remove particulate matter generated during the cleaning process to ensure the cleanliness of the cleaning water.

Ultrasonic cleaning machines are specifically designed for treating instruments with complex structures, small pores, or joints. They operate by using high-frequency ultrasound (typically 40kHz) to induce cavitation in liquids, creating millions of tiny vacuum bubbles. The shock waves generated by these bubbles' collapse can penetrate even the tiniest crevices in instruments, thoroughly removing any organic residue adhering to them. Modern ultrasonic cleaning machines are also equipped with heating systems and degassing functions to further enhance cleaning effectiveness. They require a specialized multi-enzyme cleaning agent and follow a standard "immersion-ultrasound-rinse" process.

Endoscope cleaning workstations: With the increasing popularity of endoscopy technology, endoscope cleaning equipment has become a crucial component of CSSD. These units feature a modular design and typically include a leak detector, initial rinse tank, enzyme rinse tank, rinse tank, and final rinse tank. Advanced models also feature an automated perfusion system to ensure thorough cleaning of all endoscope lumens. Made of corrosion-resistant materials and ergonomically designed, these units significantly reduce labor intensity. Cleaning and disinfection schedules must be strictly adhered to during use to ensure each step is performed thoroughly.

Instrument pre-treatment equipment: used for the initial treatment of contaminated instruments in the operating room, including moisturizing and decontamination. This type of equipment is usually installed in the junction area between the operating room and the CSSD. It can pre-treat the instruments after use in the first place to prevent blood and body fluids from drying up and increasing the difficulty of cleaning. Modern pre-treatment equipment has an automatic spraying function, which can evenly spray special moisturizers. It also has a closed storage function to prevent the spread of contamination.

(2) Sterilization equipment

Sterilization is the core of CSSD work, and its purpose is to completely kill all microorganisms, including bacterial spores. According to the sterilization principle and the applicable instruments, CSSD is mainly equipped with the following sterilization equipment:

Pulsating vacuum pressure steam sterilizer: This is the most commonly used sterilization equipment in hospitals and is suitable for medical instruments that are resistant to high temperatures and high humidity. Its working principle is to remove the air in the sterilization chamber during the pre-vacuum stage so that saturated steam can fully penetrate into all parts of the instrument. Typical sterilization parameters are: temperature 132-134℃, pressure 205.8kPa, and holding time 4-10 minutes (depending on the type of instrument). Modern sterilizers are controlled by microcomputers and can automatically record and store the key parameters of each sterilization cycle to ensure process traceability. The equipment is also equipped with biological monitoring and chemical monitoring systems to verify the sterilization effect in real time.

Hydrogen peroxide low-temperature plasma sterilization system: Designed for precision instruments that are not resistant to high temperatures, such as electronic instruments, plastic products, etc. The sterilization process consists of three stages: first, the hydrogen peroxide solution is vaporized and diffused throughout the sterilization chamber; then, a radio frequency electric field is used to generate a plasma, further enhancing the sterilization effect; and finally, residual hydrogen peroxide is removed through ventilation. The entire sterilization cycle takes approximately 50 minutes, with the temperature controlled between 45-50°C, which is harmless to heat-sensitive materials. The advantages of this type of equipment are its fast sterilization cycle and lack of toxic residues. However, its loading requirements are more stringent and it cannot process cellulosic materials or liquids.

Ethylene oxide sterilizers are primarily used for medical devices that are extremely sensitive to high temperatures and humidity, such as certain polymer products and electronic devices. Ethylene oxide is a broad-spectrum sterilant that can penetrate various packaging materials at room temperature and kill all microorganisms. Typical sterilization parameters are: temperature of 55°C, relative humidity of 60%, ethylene oxide concentration of 600 mg/L, and an exposure time of 1-6 hours. Due to the toxicity and flammability of ethylene oxide, the equipment must be equipped with comprehensive safety systems, including leak detection, explosion-proof design, and exhaust gas treatment. After sterilization, the items need to be ventilated for 12-24 hours to ensure that the residual gas is reduced to a safe level. Dry heat sterilizer: Suitable for instruments that are not resistant to moisture and heat but resistant to high temperatures, such as glassware, oils, powders, etc. Its working principle is to conduct heat through high-temperature air. The typical sterilization conditions are 160℃ for 120 minutes or 170℃ for 60 minutes. Modern dry heat sterilizers use forced convection technology to ensure uniform temperature distribution and are equipped with high-efficiency filters to ensure that no new contaminants are introduced during the sterilization process. The disadvantages of this type of equipment are long sterilization cycles and high energy consumption.

(3) Packaging and storage equipment

Proper packaging and storage are key to ensuring that sterilized items remain sterile before use. CSSD is equipped with the following specialized equipment:

Medical heat sealer: used to seal various sterilization packaging materials, such as paper-plastic bags, Tyvek packaging, etc. Modern heat sealers are controlled by microprocessors and can accurately adjust the sealing temperature and pressure to ensure the integrity and consistency of the seal. Advanced models are equipped with an integrity detection function that can automatically identify and reject packages with unqualified seals. The equipment also has a counting function that can record workload and remind you to replace the blade.

Hard sterilization container system: composed of a stainless steel body, a silicone sealing ring and a high-efficiency filter membrane, it can be reused more than 500 times. Compared with disposable packaging materials, hard containers have better protection performance, especially hard containers have better protection performance and are particularly suitable for the sterilization and storage of precision instruments. Modern container systems are equipped with intelligent identification modules that can record information such as the number of uses and sterilization cycles. Some products also have a pressure balance valve design to ensure sufficient penetration of the sterilization medium.

Sterile item storage system: including clean storage cabinets, smart shelves, etc. These devices utilize laminar flow purification technology to maintain an ISO Class 8 clean environment, effectively preventing secondary contamination of sterilized items. Intelligent storage systems automatically monitor inventory levels and record expiration dates, implementing a "first-in, first-out" management system. Some high-end products also feature automatic temperature and humidity control to ensure the storage environment meets regulatory requirements.

Packaging workbenches: Designed specifically for instrument packaging, they are constructed from anti-static and corrosion-resistant materials. These workbenches are typically divided into a clean area and a packaging area, equipped with functional modules such as instrument inspection lighting and packaging material storage racks. Modern packaging workbenches also incorporate weighing capabilities to ensure package weights meet regulatory requirements, preventing overweight from impacting sterilization effectiveness.

(4) Quality monitoring equipment

Quality monitoring is the top priority of CSSD work. The following equipment is used to ensure that the quality of each link is controllable:

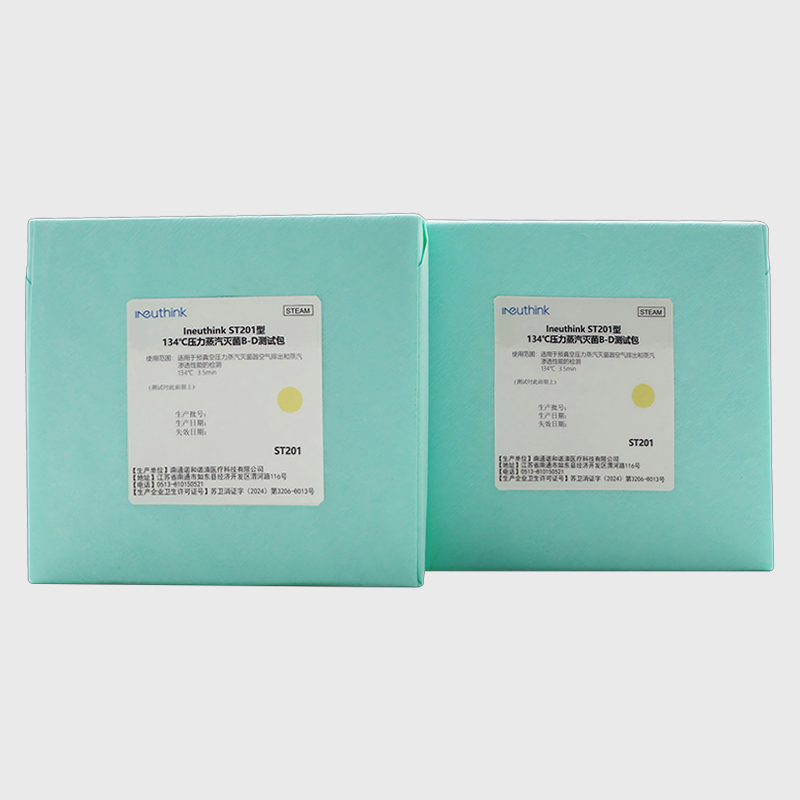

Biological monitoring system: Using thermophilic Bacillus spores as indicator bacteria, the sterilization effect is verified by culture testing. Modern biological monitoring instruments can achieve rapid culture, obtain results within 24 hours, and automatically record monitoring data.

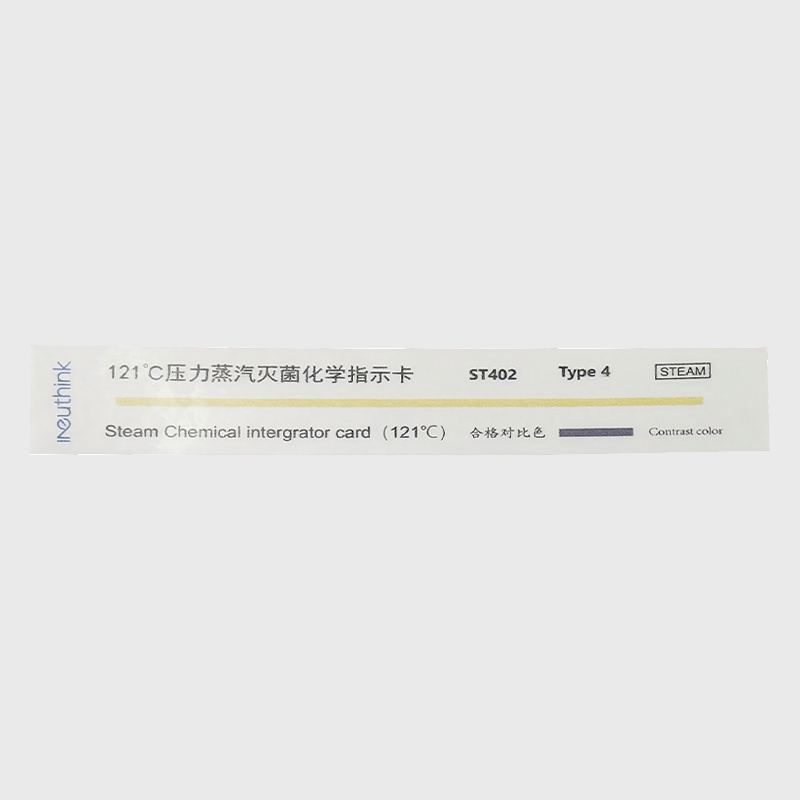

Chemical monitoring equipment: including chemical indicator card readers, crawling chemical indicator interpretation systems, etc., used to monitor the physical parameters of the sterilization process in real time.

Device testing equipment: such as magnifying glasses with light sources, endoscope detectors, etc., used to check the cleanliness and integrity of instruments.

(5) Auxiliary support equipment

Pure water treatment system: Provides cleaning water that meets the standards, usually using RO reverse osmosis + EDI deionization technology.

Intelligent traceability system: Based on RFID or barcode technology, it realizes the full life code technology of the instrument and realizes the tracking and management of the entire life cycle of the instrument.

Transportation equipment: including closed transport vehicles, automated guided vehicles (AGVs), etc., to ensure the safe transportation of instruments between departments.

3.How to manage CSSD devices?

The Central Sterilization and Supply Center (CSSD) is the core department of hospital infection control. Its equipment management is directly related to the sterilization quality of medical devices, patient safety and hospital infection control level. CSSD equipment is of various types, including cleaning, disinfection, sterilization, packaging, storage, monitoring and other equipment. Poor management may lead to sterilization failure, equipment damage, and even serious hospital infection incidents. Therefore, it is crucial to establish a scientific and standardized CSSD equipment management system.

(1) Procurement and acceptance management of CSSD equipment

1). Evaluation before equipment procurement

CSSD equipment procurement should be based on the actual needs of the hospital and consider the following factors:

Hospital size and surgical volume: Select equipment with appropriate capacity based on the amount of equipment processed.

Type of equipment: If a large number of precision instruments (such as endoscopes, electrosurgical knives, etc.) are involved, low-temperature sterilization equipment (such as hydrogen peroxide plasma sterilizers) must be equipped.

Industry standards: Equipment must comply with relevant national standards, such as China's WS 310.1-2016 "Hospital Sterilization and Supply Center Management Specifications" and ISO 13485 (Medical Device Quality Management System). Supplier Qualification: Prioritize manufacturers with comprehensive after-sales service and technical support.

2) Equipment Acceptance and Installation Verification

Upon arrival, the equipment undergoes rigorous acceptance and installation verification:

Unpacking Inspection: Verify the completeness of the equipment model, accessories, and technical documentation.

Installation Qualification (IQ): Ensure the equipment is installed in a suitable environment (e.g., power supply, water supply, exhaust system, etc.).

Check the equipment's levelness and ensure that connecting pipes are sealed.

Operational Qualification (OQ): Test basic equipment functions, such as water flow pressure in a washing machine and vacuum level in a sterilizer.

Performance Qualification (PQ): Conduct actual sterilization or cleaning tests to ensure the equipment meets its specified performance.

(2). Daily Operation and Management of CSSD Equipment

1) Standardized Operating Procedures (SOPs)

Detailed operating procedures must be established for each CSSD device, including:

Power-on Self-Test: Check the device status and parameter settings for correct operation.

Loading Requirements:

Washers: Instruments must be fully opened to avoid overlap and blocking the spray water flow.

Sterilizers: Packaged items must be properly arranged to ensure adequate penetration of steam or sterilant.

Procedure Selection:

Select the appropriate sterilization procedure (e.g., high-pressure steam sterilization, low-temperature sterilization) based on the instrument material.

Record key parameters (temperature, pressure, time, etc.) for each sterilization cycle.

Abnormal Handling:

If the device alarms or operates abnormally, immediately stop use and report a repair.

2) Equipment Usage Records

Operation Log: Record daily equipment operation status, including sterilization batches, operators, operating parameters, etc.

Maintenance Log: Record equipment maintenance and repairs to ensure traceability.

(3) Maintenance and care management of CSSD equipment

1) Daily maintenance Cleaning equipment: Check whether the spray arm is unobstructed and the filter is clean every day. Regularly replace cleaning agents and lubricants. Sterilization equipment: Check whether the door seal is intact and the vacuum pump oil level is normal every day. Regularly clean the scale in the sterilization chamber. Packaging equipment: Check whether the heat sealer blade is sharp and whether the sealing temperature is stable.

2) Regular professional maintenance Quarterly maintenance: The manufacturer or professional engineers perform in-depth maintenance, such as replacing the sealing ring, calibrating the sensor, etc. Annual inspection: Perform pressure vessel inspection on the sterilizer to ensure compliance with safety standards.

(4) Quality control management of CSSD equipment

1) Physical monitoring Monitor the sterilization parameters (temperature, pressure, time) in real time to ensure compliance with standards. Use chemical indicator cards (such as Class 5 mobile chemical indicator cards) to verify the sterilization effect.

2). Biological monitoring

Biological monitoring should be conducted at least once a week:

High-pressure steam sterilizer: Use the spores of Geobacillus stearothermophilus.

Ethylene oxide sterilizer: Use the spores of Bacillus atrophaeus.

Rapid biological monitoring: Some equipment supports 2-4 hours of rapid culture to improve monitoring efficiency.

3). Environmental monitoring

Sterile item storage area:

Carry out air culture regularly to ensure that the cleanliness requirements are met (such as ≤4 CFU/dish·30min).

Temperature and humidity control between equipment:

The temperature in the sterilization area should be controlled at 18-24℃ and the humidity at 40-60%.

(5) Personnel training and management of CSSD equipment

1). Operator training

Pre-job training:

Learn the equipment principles, operating procedures, and emergency response measures.

Only after passing the assessment can the equipment be operated independently.

Regular refresher training:

Operation skills assessment is conducted every six months to ensure personnel proficiency.

2). Management personnel training

Quality control training:

Learn sterilization monitoring methods and data analysis.

Equipment management training:

Understand the key points of equipment maintenance and troubleshooting methods.

(6) Emergency management of CSSD equipment

1). Equipment failure emergency plan

Backup equipment: Key equipment (such as sterilizers) should be equipped with backup equipment to prevent sudden failures from affecting surgery.

Emergency alternative plan:

If the sterilizer fails, contact the CSSD of a nearby hospital for assistance.

2). Sterilization failure handling

Recall mechanism:

If biological monitoring fails, all instruments in the batch must be traced and re-sterilized.

Cause analysis:

Check equipment parameters, loading methods, packaging materials, etc. to find the root cause of the problem.

CSSD equipment maintenance points table:

| Equipment Type | Maintenance Item | Maintenance Content | Maintenance Frequency | Record Requirements |

| Washer-Disinfector | Spray Arm Inspection | Check for smooth rotation and nozzle blockage. | Daily | Record any abnormalities |

| Filter Cleaning | Remove and rinse the filter to remove any residue. | Weekly | Record the cleaning date. | |

| Seal Inspection | Inspect the hatch seal for signs of deterioration or cracking. | Monthly | Take photos for documentation or replace the seal. | |

| Water System Descaling | Clean the pipes and water tank using a dedicated descaling agent. | Quarterly | Record the descaling date and batch number. | |

| Autoclave | Vacuum Pump Maintenance | Check the oil level and replace the vacuum pump oil if necessary. | Monthly | Record the oil brand and replacement date. |

| Sterilization chamber cleaning | Remove scale and residue from the chamber | Weekly | Record cleaning status | |

| Safety valve calibration | Test pressure relief function for proper function | Annual (mandatory inspection) | Maintain inspection report | |

| Pipeline leak detection | Inspect steam pipes and joints for leaks | Quarterly | Record inspection results | |

| Low-temperature sterilization equipment | Hydrogen peroxide concentration measurement | Calibrate concentration sensors to ensure accurate sterilant delivery | Monthly | Record calibration data |

| (Plasma/Ethylene Oxide) | Gas tank seal inspection | Check sterilant tank connections for leaks | Every time a gas tank is replaced | Record the person performing the inspection |

| Biological Monitoring System | Incubator Temperature Verification | Use a standard thermometer to verify the actual incubator temperature (56 ± 2°C). | Monthly | Record temperature fluctuations. |

| Spore Tablet Expiration Date Management | Check that the biological indicator is within its expiration date. | Before each use, | Record the batch number and expiration date. |

Maintenance Considerations:

Preventive Maintenance: Create a maintenance calendar and schedule regular maintenance in advance.

Spare Parts Management: Stock up on critical wear parts (seals, filters, etc.).

Double Verification: After major maintenance, two people must verify the equipment's status.

Abnormal Reporting: Immediately deactivate equipment and report any performance degradation.

4.What are the common faults of CSSD equipment?

The Central Sterilization Supply Center (CSSD) is an important line of defense for hospital infection control. The stability of its equipment operation is directly related to the sterilization quality of medical devices and patient safety. In actual work, various CSSD equipment may malfunction due to mechanical wear, improper operation or environmental factors. If not handled in time, serious consequences may occur. This article will systematically introduce the common types of failures, causes and scientific response methods of CSSD core equipment.

(1) Typical failures of cleaning and disinfection systems

Cleaning and disinfection equipment is the first link in the CSSD workflow. Its failure often leads to subsequent sterilization failure. The most common failure is abnormal operation of the spray arm, which is manifested as rotation jamming or complete stoppage. This is usually due to long-term deposition of minerals in high-pressure water blocking the spray hole, or lack of lubrication of the bearing leading to increased mechanical resistance. In actual operation, if the spray arm is found to be abnormal, it should be stopped immediately and the spray hole should be cleaned with a special needle. If necessary, the bearing lubricant should be replaced. The key to preventing such failures is to establish a regular maintenance system. It is recommended to disassemble and clean the spray structure every week and perform deep maintenance every quarter.

Another common problem is incomplete drying of the equipment. When water stains are found on the surface or lumen of the instrument, it is necessary to focus on checking the working status of the heating element and the speed of the drying fan. Cases in many hospitals have shown that incomplete drying is often caused by the accumulation of impurities such as lint on the air duct filter, resulting in poor hot air circulation. Therefore, monthly cleaning of the air duct filter should be a standard maintenance item. For emergency surgical instruments, a spare drying cabinet can be activated for emergency use, but its temperature calibration must be accurate.

(2) Emergency handling of sterilization equipment failure

Sterilization equipment failure is the most serious operational risk of CSSD. The most typical failure of high-pressure steam sterilizers is vacuum system abnormality, which is manifested as vacuum stage alarm or Bowie-Dick test failure. This situation is mostly caused by the contamination and deterioration of the vacuum pump oil, which loses its lubrication and sealing function, or leakage in the steam pipe joints. Experience has shown that the use of inferior steam (too high water content) will accelerate the damage of the vacuum pump. When a vacuum failure occurs, a gravity displacement sterilization procedure can be temporarily used, but the instrument packaging size must be shortened to ensure the steam penetration effect.

Hydrogen peroxide low-temperature sterilization system often faces the problem of sterilant injection failure. It has been observed that when the ambient humidity is too high (>70%RH), the hydrogen peroxide cartridge is prone to absorb moisture and crystallize, causing partial blockage of the injection line. At this time, the system's built-in pipeline flushing program should be executed at least 3 times, and a new batch of sterilant cartridges should be replaced. It is worth noting that hydrogen peroxide residue detection must use special test paper, and ordinary chemical indicator cards cannot accurately reflect the actual residual amount. The most dangerous situation of an ethylene oxide sterilizer is gas leakage. Because ethylene oxide is carcinogenic and has the risk of explosion, once the unique sweet smell or eye irritation is smelled, the emergency plan must be activated immediately: evacuate people within a radius of 10 meters, turn off the power, and turn on the emergency exhaust system. Only after using a professional PID detector to confirm that the concentration is less than 1ppm can fault troubleshooting be carried out. Routine maintenance of such equipment should pay special attention to the integrity check of the door seal. Any slight crack may cause slow leakage.

(3) Chain effects of failure of auxiliary equipment

Failure of packaging equipment is often easily overlooked, but may cause serious consequences. A typical problem is that the heat sealer seals loosely. When it is found that the paper and plastic packaging bag is easy to tear or there are bubbles at the seal, it usually indicates that the heating blade has been worn out (the general life is 5,000 seals) or the temperature sensor has drifted. The temporary solution is to use sterilization indicator tape for manual reinforcement, but the sealing test must be carried out at the same time. The failure of the intelligent traceability system is mainly manifested as barcode scanning failure, which is mostly caused by contamination of the scanning window or interruption of software communication. During maintenance, the cleanliness of the optical reader should be checked.

Failure of the pure water treatment system is manifested as a sudden increase in the conductivity of the produced water. Practice shows that about 80% of the cases are caused by RO membrane perforation or resin column failure. At this time, it is necessary to immediately switch to the spare water tank and perform an integrity test on the system. It is worth noting that timely replacement of the pretreatment filter (at least once a month) can effectively extend the service life of the RO membrane.

(4)Systematic strategy for fault management

Establishing a three-level response mechanism is a scientific method for handling CSSD equipment failures. Level 1 failures (such as spray arm blockage) can be solved on-site by trained operators; level 2 failures (such as sensor calibration) require intervention by equipment engineers; level 3 failures (such as sterilant leakage) must contact the manufacturer's professional technical support. All fault handling must record the fault code, occurrence time, treatment measures and verification results in detail. These data are crucial for optimizing preventive maintenance plans. It should be noted that any failure involving pressure vessels (such as steam sterilizers) or toxic gases (such as ethylene oxide) must follow the "safety first" principle. When there is uncertainty about the status of the equipment, it is better to suspend use than to take risks. It is recommended to organize simulated fault emergency drills every quarter, focusing on training personnel on the ability to interpret biological monitoring results, because this is the gold standard for verifying whether equipment failures affect sterilization quality. Through systematic fault management and preventive maintenance, the operational reliability of CSSD equipment can be significantly improved. Data shows that hospitals that implement scientific maintenance plans can reduce the rate of sudden equipment failures by more than 60%. This not only ensures medical safety, but also significantly reduces the risk of clinical surgery delays caused by equipment discontinuation.

List of common CSSD equipment failures and solutions:

| Equipment Type | Common Failure Symptoms | Possible Causes | Emergency Measures | Preventive Maintenance Recommendations |

| Washer-disinfector | Spray arm not rotating | Spray orifice clogged/bearing damaged/motor failure | Manual rotation test, emergency use of backup equipment | Check spray orifices weekly and lubricate bearings quarterly |

| High-pressure steam sterilizer | Vacuum level not meeting standards | Vacuum pump oil contamination/pipeline leak/sensor failure | Switch to gravity displacement sterilization procedure | Change vacuum pump oil monthly |

| Hydrogen Peroxide Plasma Sterilizer | Sterilant injection failure | Cartridge not punctured/Line blocked by crystals | Replace the cartridge and perform the line flush procedure | Test injection after each cartridge change |

| Ethylene oxide sterilizer | Sterilant Leak Alarm | Loose Tank Connection/Ruptured Pipe | Immediately evacuate personnel and ventilate the area | Install a leak detection system |

| Packaging equipment | Poor seals | Blade wear/temperature sensor drift | Artificial tape reinforcement | Verify seal quality daily with test bags |

| Water treatment system | Increased product water conductivity | RO membrane damage/resin column failure | Switching to backup water tank | Weekly water quality testing |

| Biomonitoring Incubator | Culture Temperature Fluctuation | Heating Module Aging/Temperature Sensor Drift | Switch to Third-Party Laboratory Testing | Monthly Verification with a Standard Thermometer |

General Troubleshooting Principles:

Immediately discontinue use: Immediately discontinue use if a fault affecting sterilization quality occurs.

Graded Response:

Primary faults (e.g., spray arm blockage): Handle by the department's equipment manager.

Intermediate faults (e.g., sensor drift): Contact the manufacturer's engineer.

High-level faults (e.g., sterilant leakage): Activate the emergency plan.

Special Considerations:

Ethylene oxide leaks: Use a dedicated detector (such as a PID detector) to confirm safe concentrations.

Steam sterilizer safety valve tripping: Must be inspected by the special equipment regulatory authorities before reactivation.

Hydrogen peroxide residue: Use a dedicated test strip to test the residual concentration in the chamber (should be <1 ppm).

5.Frequently Asked Questions about CSSD Devices

Q1: What should I do if the washer-disinfector spray arm isn't rotating?

Possible causes: Clogged spray holes, damaged bearings, motor failure.

Solution:

Immediately stop the machine, check for clogged spray holes, and clear them with a fine needle.

Check the bearings for oil depletion or damage, and replace if necessary.

If the motor is faulty, contact an engineer for repair.

Preventative measures: Clean the spray arms weekly and lubricate the bearings quarterly.

Q2: Are there still water stains on instruments after cleaning?

Possible causes: Drying function failure, damaged heating element, or humidity sensor failure.

Solution:

Check that the drying fan is operating properly.

Test the resistance of the heating element to confirm it's burned out.

Temporarily use backup drying equipment or perform manual drying.

Preventative measures: Test the drying function monthly and clean the air duct filters regularly.

Q3: Is the vacuum level in the autoclave not meeting the specified level?

Possible causes: Vacuum pump oil contamination, pipe leaks, or excessive water content in the steam.

Solution:

Replace the vacuum pump oil (recommended monthly).

Check the pipe seals and repair any leaks. Temporarily switch to gravity-displacement sterilization.

Preventive Measures: Check steam quality daily and regularly maintain the vacuum system.

Q4: Hydrogen peroxide plasma sterilization failure?

Possible causes: Failed sterilant injection, insufficient instrument drying, excessive chamber humidity.

Solution:

Perform a line flushing procedure and replace the cartridge.

Extend instrument drying time (at least 30 minutes).

Ensure ambient humidity is ≤ 60% RH.

Preventive Measures: Regularly calibrate the hydrogen peroxide concentration sensor.

Q5: How often should the CSSD equipment be maintained?

Recommended frequency:

Daily: Surface cleaning and functional inspection.

Weekly: Filter cleaning and water quality testing.

Monthly: Sensor calibration and seal inspection.

Yearly: Pressure vessel inspection and comprehensive maintenance.

Q6: What are the emergency procedures in the event of equipment failure?

Steps:

Immediately deactivate the faulty equipment and activate the backup equipment.

Record the fault code and symptoms and contact an engineer.

Reprocess or recall the affected equipment. Note: When pressure vessels or toxic gases are involved, personal safety is the priority.

English

English Español

Español Français

Français

CONTACT US

CONTACT US