Medical Trocar Suppliers

Trocars are mainly used to puncture the abdominal wall of the human body, establish a working channel into the abdominal cavity, and provide a channel for the injection of carbon dioxide gas.

Trocars usually consist of a puncture needle and a cannula, where the puncture needle is used to penetrate the abdominal wall, while the cannula is used to maintain pneumoperitoneum and provide an access channel for endoscopes and surgical instruments.

By injecting carbon dioxide gas, a stable abdominal pressure is formed, providing a clear operating field and sufficient operating space for surgery. This process not only reduces surgical trauma but also speeds up postoperative recovery.

With a building area of 20,310 square metres, the company has a class 100,000 purified production workshop, a class 10,000 microbiology testing room, a local class 100 physical and chemical laboratory, and a standardised storage system for raw materials and finished products.

Since the initial batch of products were launched in 2013, Eray has continuously enriched its product categories. Our products have covered protective masks, nursing consumables, sensory control consumables, surgical instruments, providing safe, efficient and environmentally friendly disposable medical solutions for medical institutions worldwide.

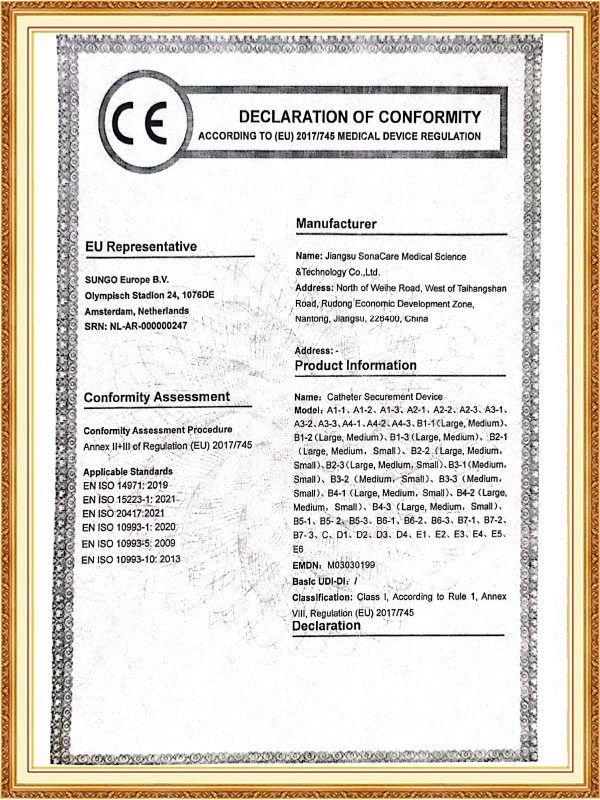

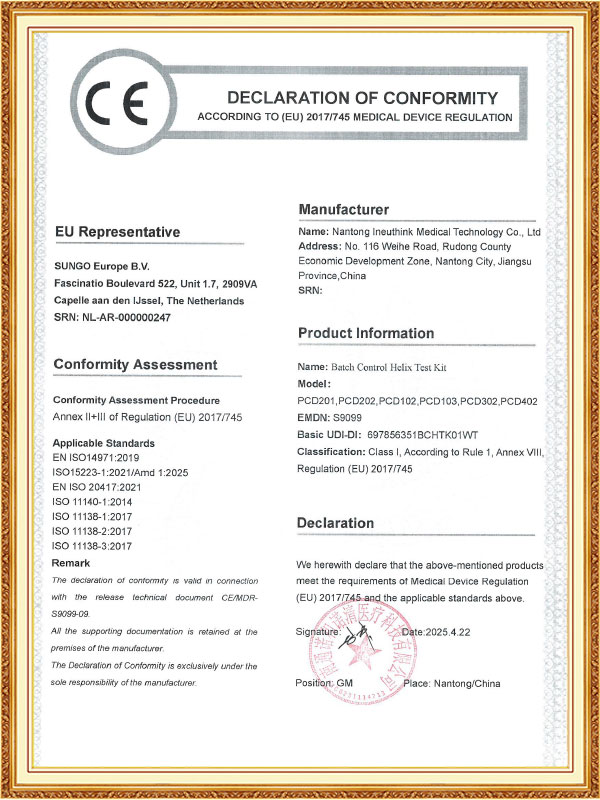

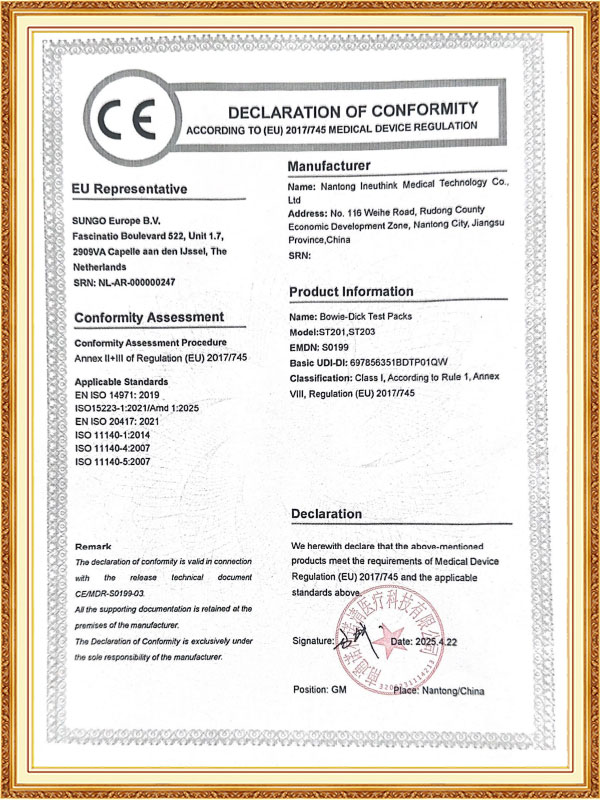

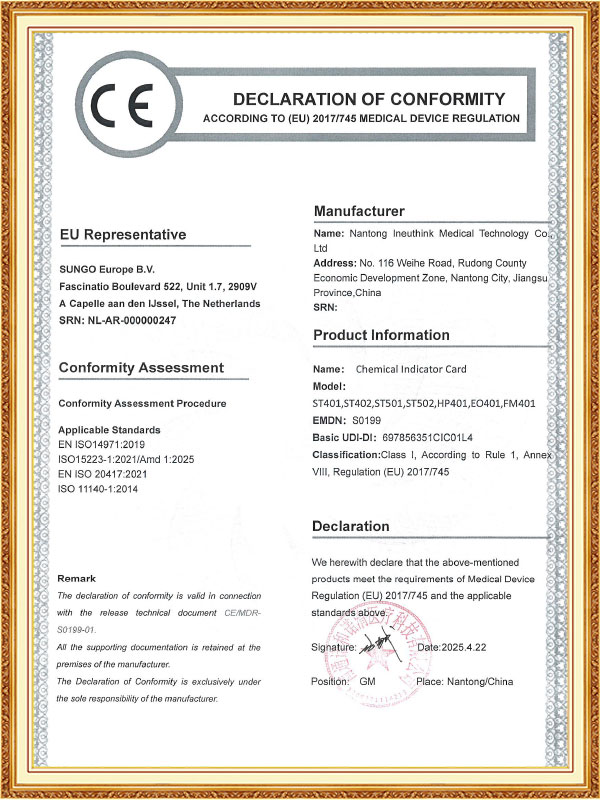

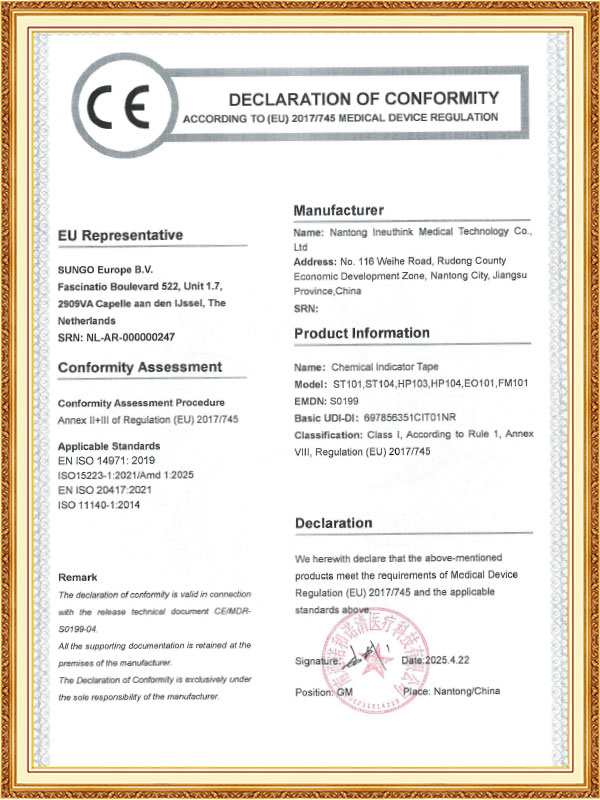

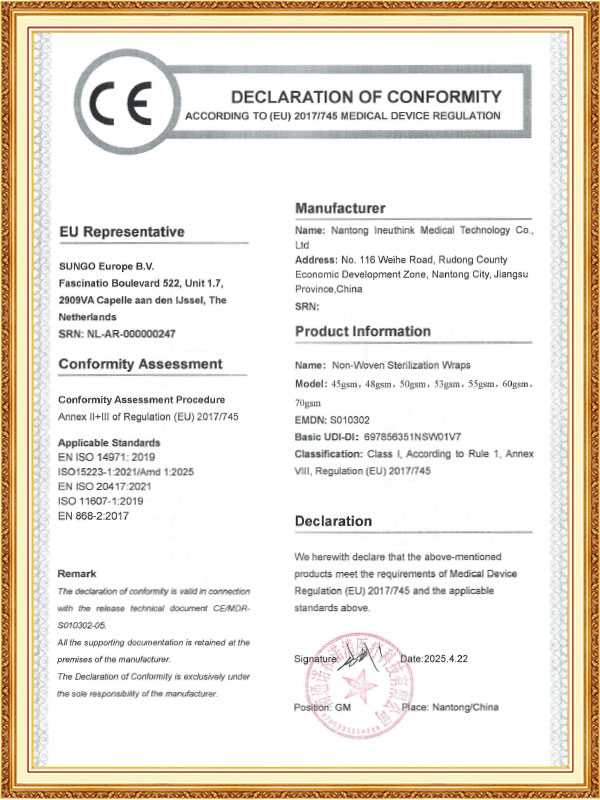

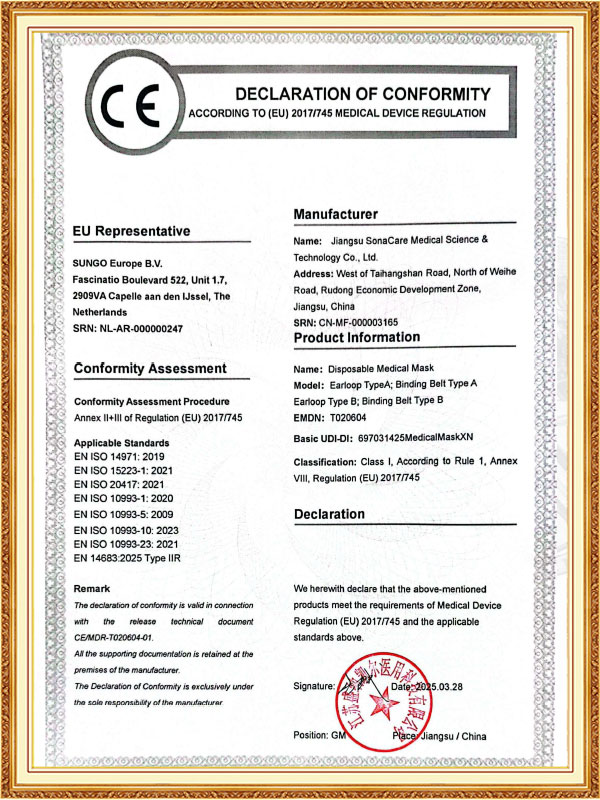

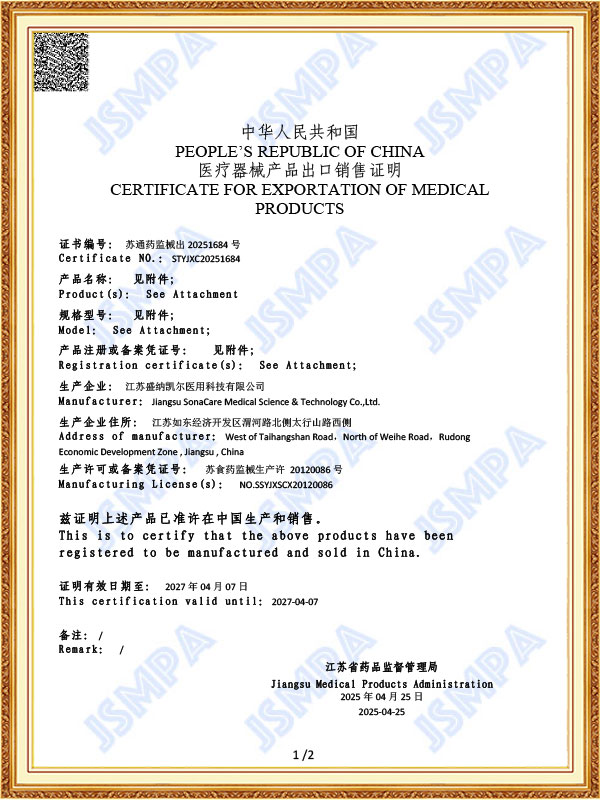

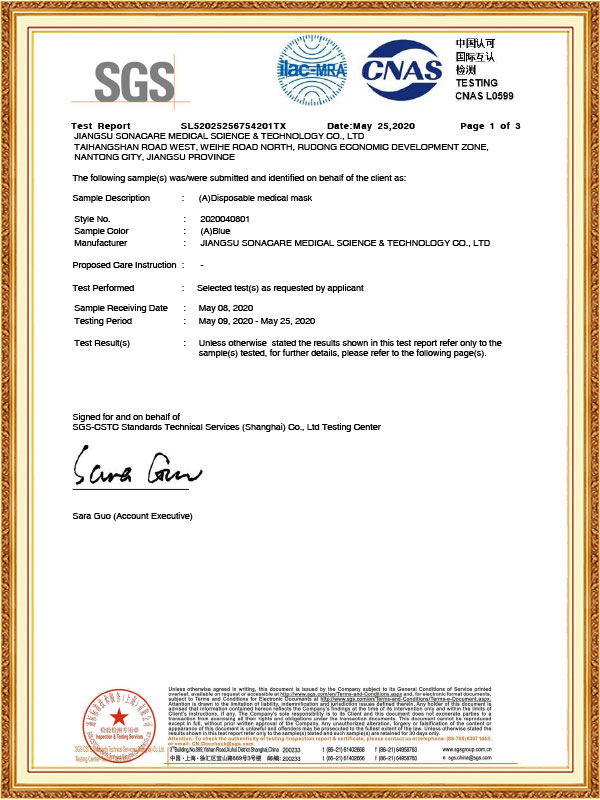

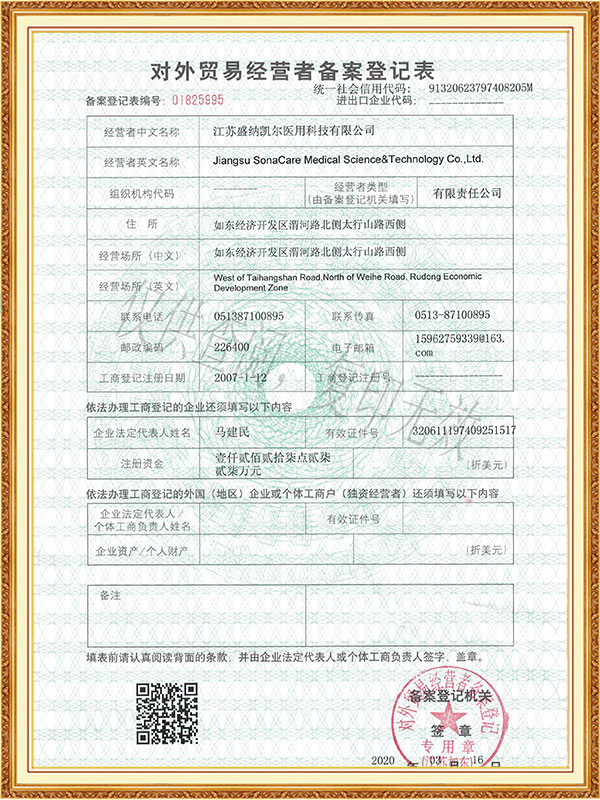

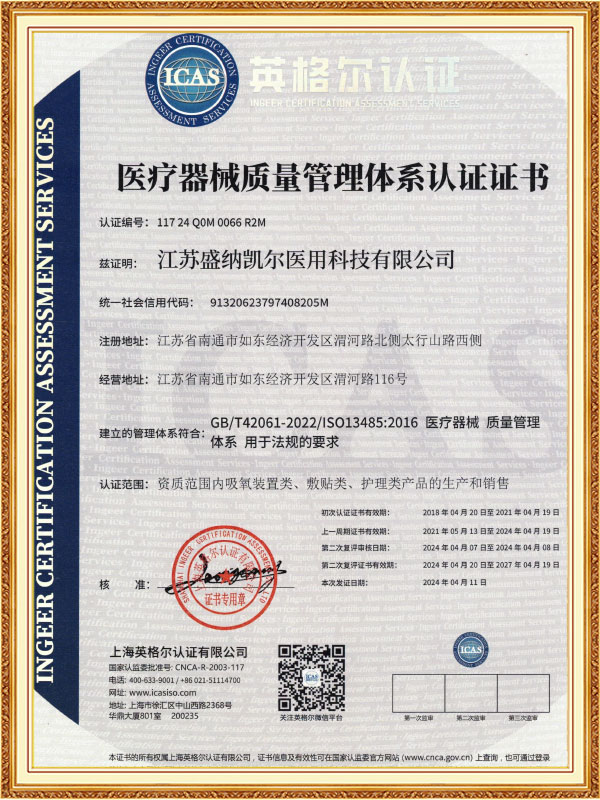

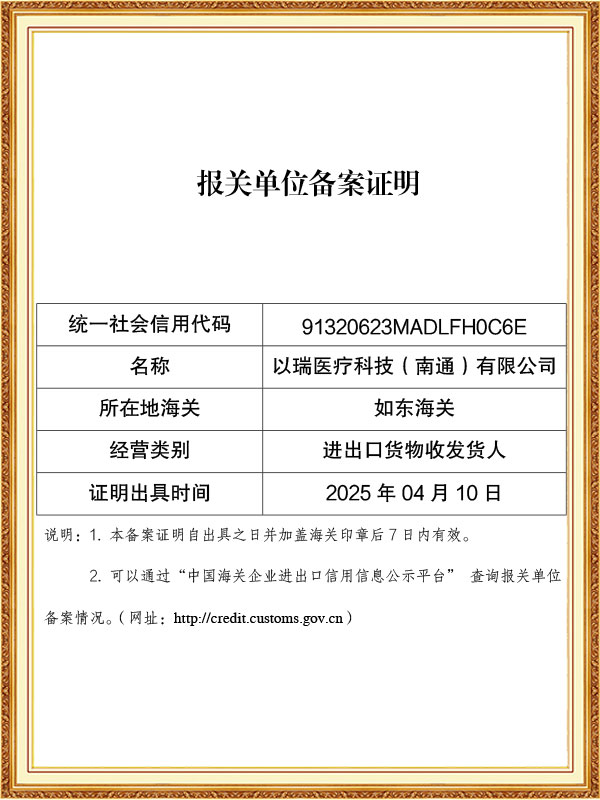

As a professional OEM Medical Trocar Suppliers and ODM Medical Trocar Factory, The company has passed ISO 13485 and other quality system certifications, and some of its products have obtained CE certification and FDA filing permits, and has established long-term cooperative relationships with many domestic and foreign medical institutions and distributors.

-

Feb 27. 2026

Can Optical Trocars Reduce the Risk of Organ Injury?Optical Trocars Significantly Reduce Organ Injury Risk Yes, optical trocars can significantly reduce the risk of organ injury during laparoscopic surgery by allowing surgeons to visualize tissue layers in real time as the instrument passes through the abdominal wall. Unlike blin...

Read More -

Feb 20. 2026

What is an Optical Trocar and Why is it Essential in Medical Procedures?What is an Optical Trocar and Why is it Essential in Medical Procedures? An optical trocar is a specialized surgical instrument used primarily in minimally invasive procedures. It combines the functions of a trocar and a visual scope, allowing surgeons to create an access point ...

Read More -

Feb 13. 2026

What Are the Common Problems With Medical Trocars and How to Avoid Them?What Are the Most Common Problems With Medical Trocars? The most common problems with medical trocars include insertion injuries, gas leakage, dull blades, instability, and contamination risks. These issues can compromise surgical safety, increase operating time, and raise posto...

Read More

The function of a trocar is to safely penetrate the abdominal wall and maintain a stable pneumoperitoneum. It consists of two precisely coordinated components: a sharp needle that penetrates the various layers of the abdominal wall, and a cannula that remains in place as a permanent channel. This design concept perfectly addresses the access challenge of minimally invasive surgery: the sharp needle is withdrawn after initial penetration, leaving behind a smooth cannula that serves as a portal for surgical instruments and endoscopes. This separate design not only ensures a safe and controlled puncture process but also provides a stable operating environment.

Once the needle has penetrated the various layers of the abdominal wall, the cannula is secured in place. Through this established channel, carbon dioxide is precisely infused into the abdominal cavity, creating the required 12-15 mmHg pneumoperitoneum pressure for surgery. This artificially created operating space provides the surgeon with a clear window for observation and operation, providing a clear surgical field of view while ensuring ample space for instrument manipulation. The entire system acts as a precise pressure balancer, maintaining surgical requirements while minimizing disruption to the patient's physiological functions.

From a product perspective, modern trocars embody the highest standards of medical device manufacturing. The puncture needle is constructed from medical-grade stainless steel and undergoes a special heat treatment process, ensuring both sufficient puncture strength and a sharp edge. The cannula is constructed from a polymer material with excellent biocompatibility, and its smooth surface treatment reduces tissue friction. Innovative safety features, such as a disposable, spring-loaded protective sheath, effectively prevent accidental puncture wounds during surgery. Some high-end products are also equipped with a rotary locking mechanism, anti-leak valves, and multiple instrument channels, further enhancing surgical safety and convenience. This minimally invasive technique avoids the large incisions required for traditional open surgery, significantly reduces postoperative pain, significantly shortens recovery time, and significantly reduces the number of days in the hospital. Furthermore, meticulous operating conditions enable more precise surgery and reduce the risk of intraoperative bleeding and complications.

Trocars are critical instruments in laparoscopic surgery, and their maintenance directly impacts surgical safety and patient recovery. Immediately after daily use, the lumen should be thoroughly rinsed with running pure water. Use a soft-bristled brush to gently remove blood stains and tissue residue from the inner and outer surfaces of the needle and cannula, paying particular attention to the cleanliness of the needle tip and cannula valve. After cleaning, the lumen should be blown dry with a high-pressure air gun to prevent residual moisture and corrosion. Weekly, the sharpness and integrity of the needle tip should be inspected with a magnifying glass, and the seal of the cannula valve should be tested to ensure proper pneumoperitoneum maintenance. All detachable components should be disassembled before sterilization. High-temperature-resistant materials should be sterilized with high-pressure steam at 134°C, while precision components should be sterilized with low-temperature plasma. During storage, the needle and cannula should be kept separate in a dedicated instrument box to prevent damage from collision. Before each use, the trocar's overall integrity should be inspected and the airtightness tested to ensure smooth and unobstructed puncture. A usage registration system should be established to record the sterilization date, number of uses, and maintenance status, and instruments that have reached their end of life should be replaced promptly. Through standardized maintenance and management, not only can the service life of the trocar be extended, but the safety of the operation can also be ensured, providing patients with better treatment effects.

English

English Español

Español Français

Français

CONTACT US

CONTACT US