Eray MedTech Surgical Portfolio: Precision in Minimally Invasive Procedures

Trocars:

Core laparoscopic access devices for creating stable surgical channels.

Enable multi-port instrumentation with minimal tissue trauma.

Surgical Staplers:

Deliver rapid wound closure and anastomosis through automated staple deployment.

Reduce intraoperative time vs. manual suturing.

Ligation Systems:

Provide secure vessel occlusion to prevent hemorrhage.

Mitigate postoperative complications.

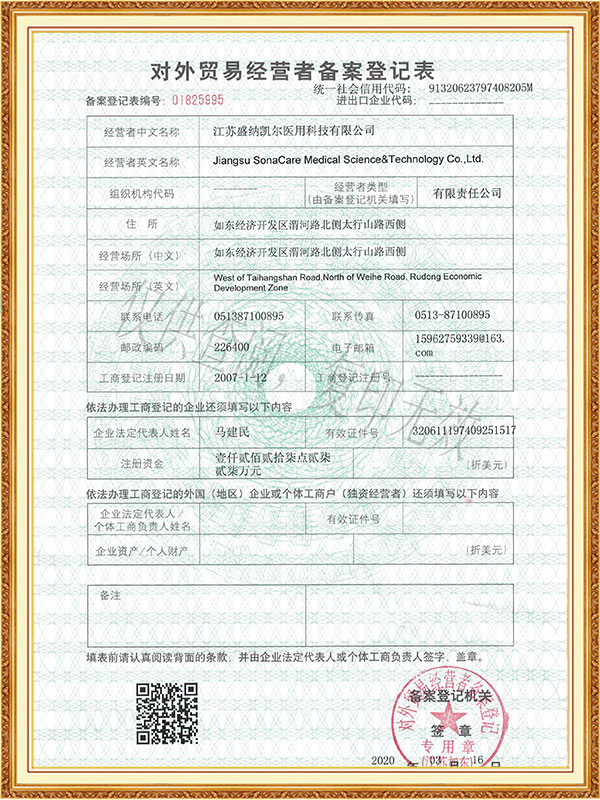

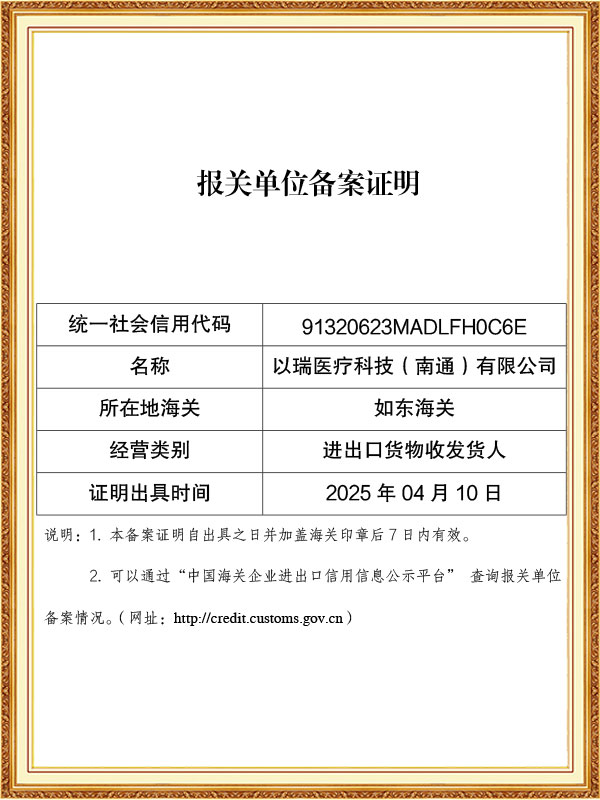

Eray Medical Technology (Nantong) Co., Ltd, focusing on the field of medical devices, is an integrated enterprise of industry and trade integrating R&D, production and sales. The company's manufacturing base is located in Rudong Economic Development Zone in Jiangsu Province, which has a favourable geographical location, convenient traffic and a good supporting environment for industrial clusters.

With a building area of 20,310 square metres, the company has a class 100,000 purified production workshop, a class 10,000 microbiology testing room, a local class 100 physical and chemical laboratory, and a standardised storage system for raw materials and finished products.

Since the initial batch of products were launched in 2013, Eray has continuously enriched its product categories. Our products have covered protective masks, nursing consumables, sensory control consumables, surgical instruments, providing safe, efficient and environmentally friendly disposable medical solutions for medical institutions worldwide.

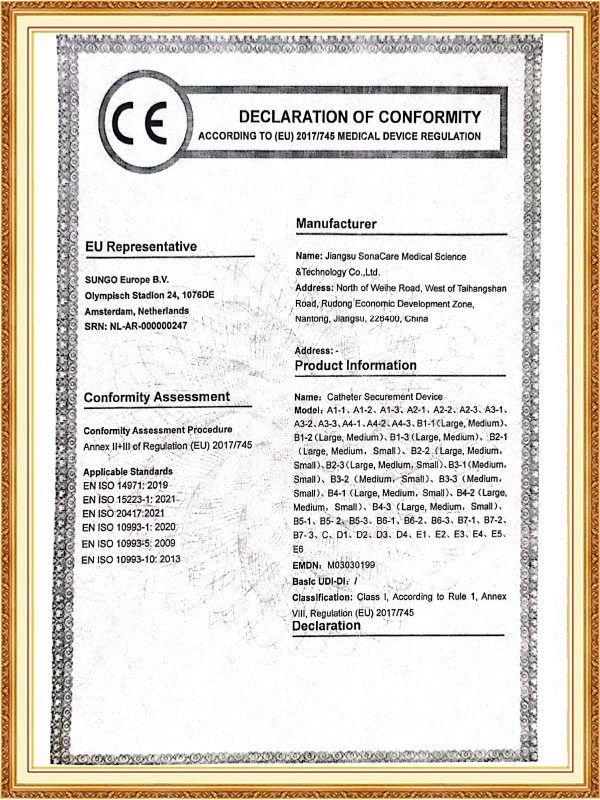

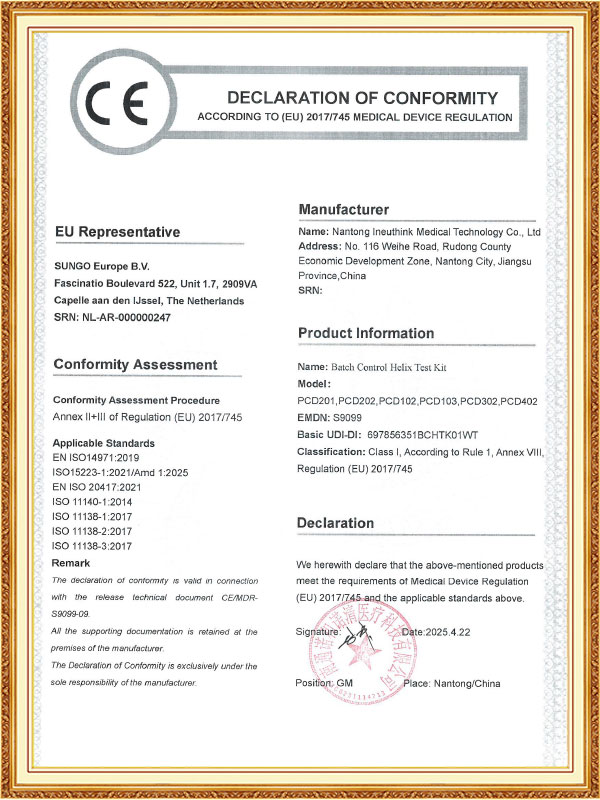

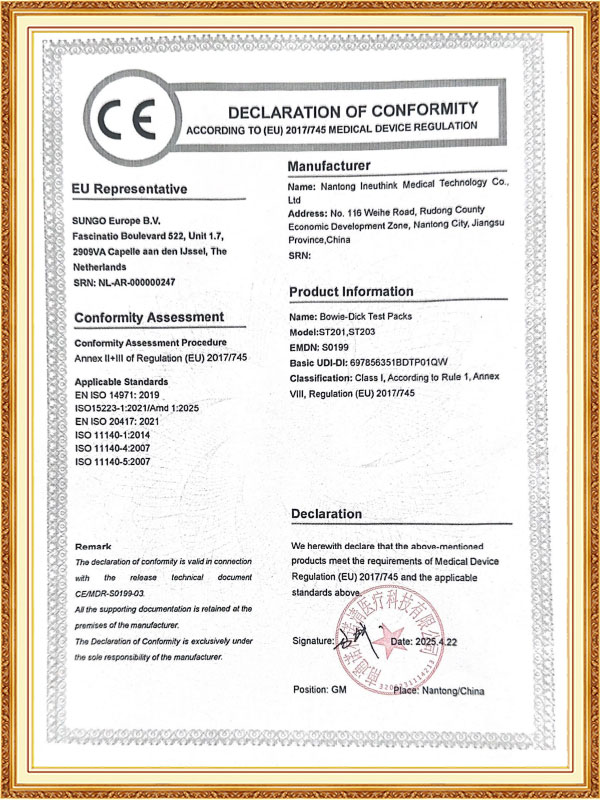

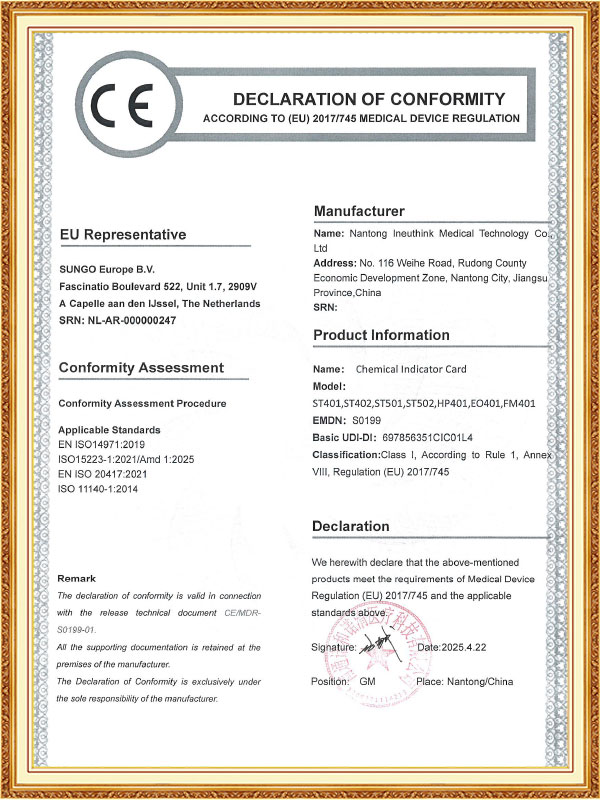

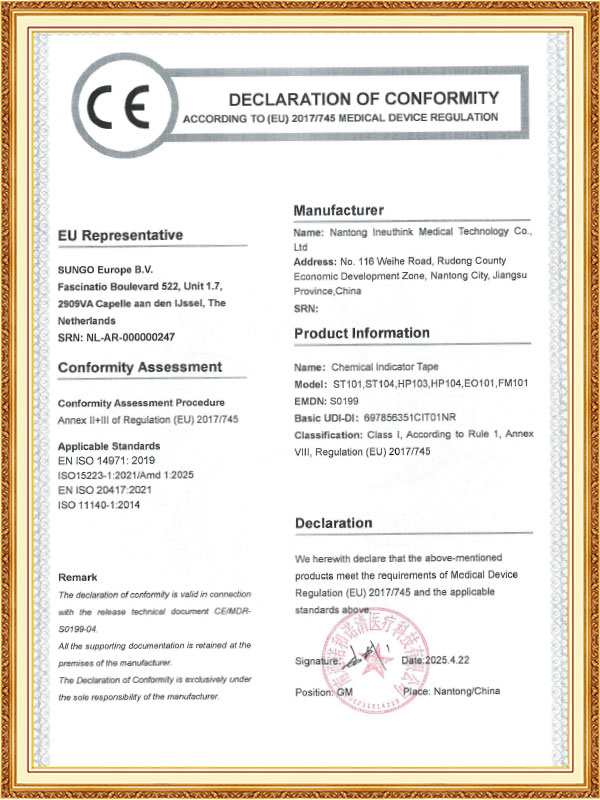

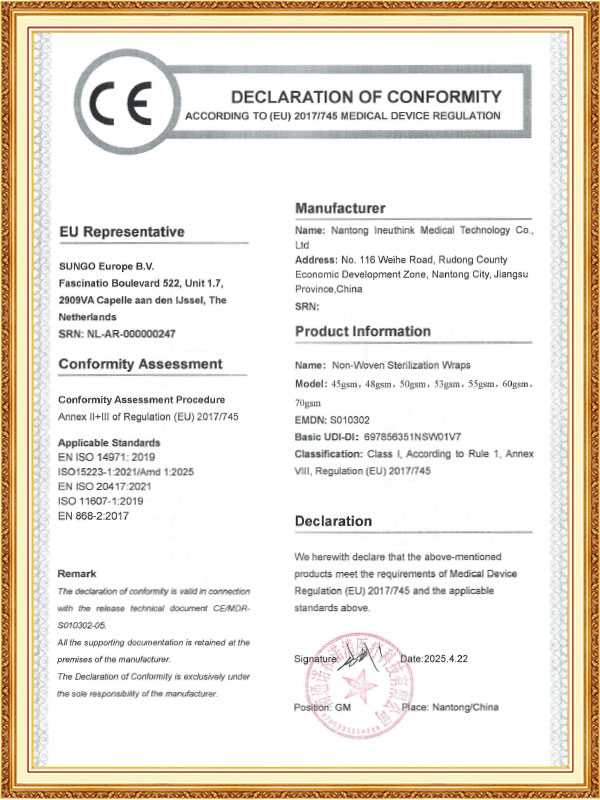

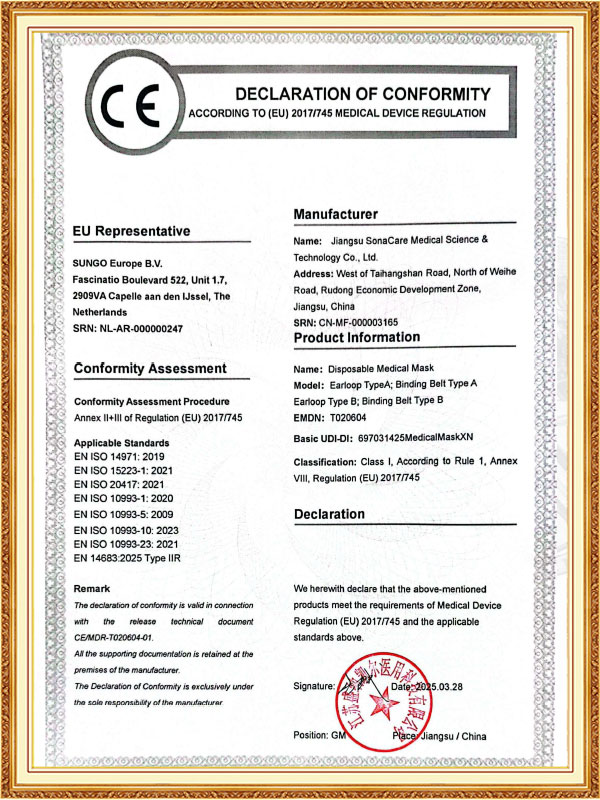

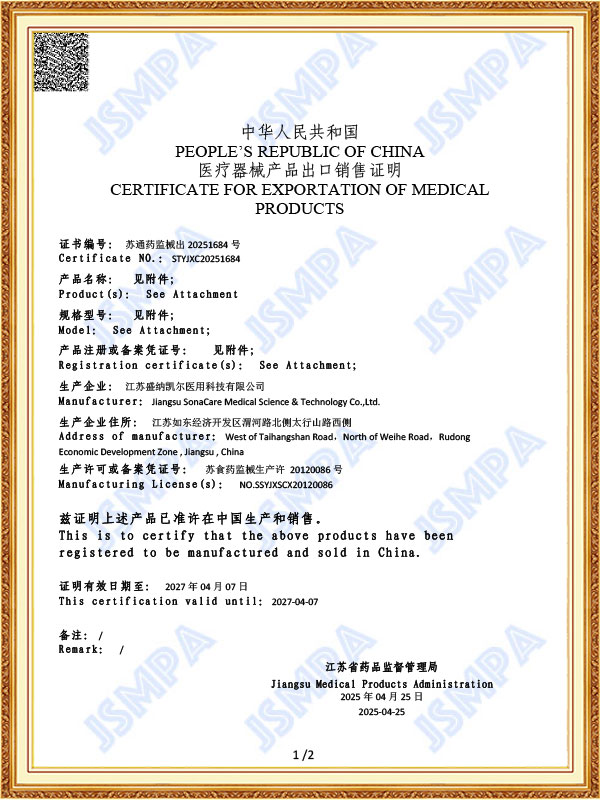

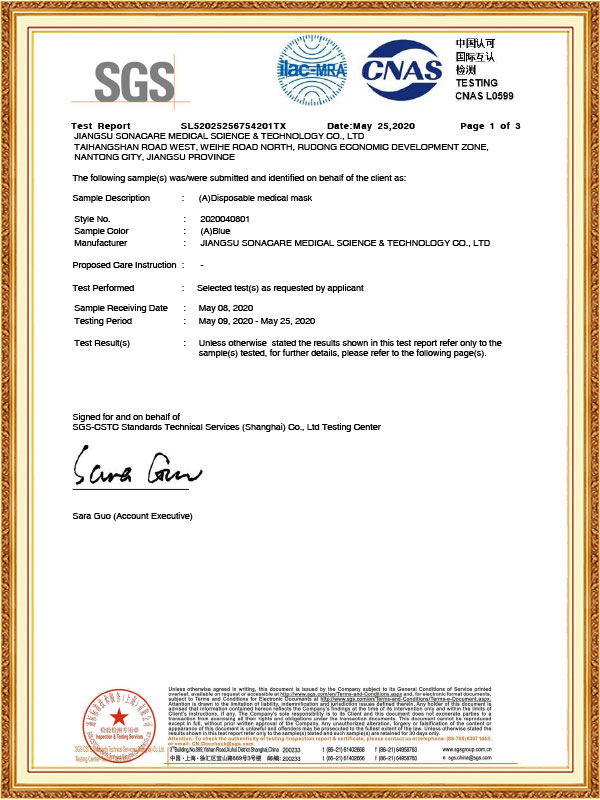

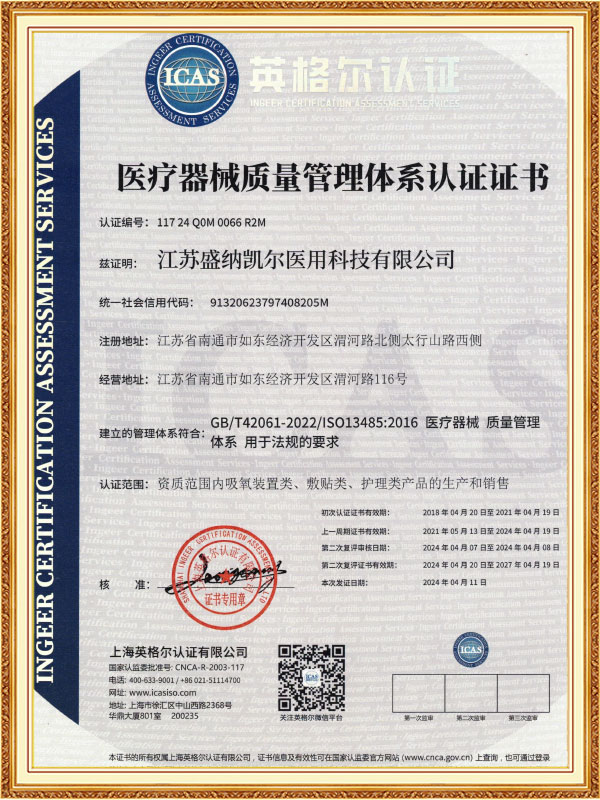

The company has passed ISO 13485 and other quality system certifications, and some of its products have obtained CE certification and FDA filing permits, and has established long-term cooperative relationships with many domestic and foreign medical institutions and distributors.

-

Feb 27. 2026

Can Optical Trocars Reduce the Risk of Organ Injury?Optical Trocars Significantly Reduce Organ Injury Risk Yes, optical trocars can significantly reduce the risk of organ injury during laparoscopic surgery by allowing surgeons to visualize tissue layers in real time as t...

Read More -

Feb 20. 2026

What is an Optical Trocar and Why is it Essential in Medical Procedures?What is an Optical Trocar and Why is it Essential in Medical Procedures? An optical trocar is a specialized surgical instrument used primarily in minimally invasive procedures. It combines the functions of a trocar and ...

Read More -

Feb 13. 2026

What Are the Common Problems With Medical Trocars and How to Avoid Them?What Are the Most Common Problems With Medical Trocars? The most common problems with medical trocars include insertion injuries, gas leakage, dull blades, instability, and contamination risks. These issues can compromi...

Read More

Amidst the rapid advancements in minimally invasive surgical technology, Eray MedTech provides precise and efficient solutions for the modern operating room with its innovative surgical product portfolio. Our surgical instrument portfolio is designed specifically for minimally invasive surgery, ensuring safety while improving efficiency and delivering a superior surgical experience for both doctors and patients.

The innovative design of the trocar, a key access device in laparoscopic surgery, ensures stable surgical access. The multi-channel operating system enables surgeons to simultaneously operate multiple instruments, improving surgical efficiency. The revolutionary breakthrough of surgical staplers has transformed traditional suturing methods. Through the precise deployment of automated staples, they achieve rapid wound closure and perfect anastomosis. Clinical data demonstrates that using our staplers can reduce intraoperative time by over 30% compared to traditional manual suturing, while ensuring consistent suture quality. This efficient procedure not only reduces the surgeon's burden but also saves valuable surgical time for patients.

The ligation system demonstrates superior performance in vascular management. Its precise closure mechanism provides reliable vascular occlusion, effectively preventing the risk of intraoperative bleeding. Clinically proven, this system significantly reduces the incidence of postoperative complications in patients using it, providing a strong guarantee for surgical safety. The system's ergonomic design allows surgeons to maintain stability and precision during prolonged surgeries.

Eray MedTech consistently adheres to the philosophy of "precision medicine" and continuously advances technological innovation in surgical instruments. Our R&D team collaborates closely with clinical experts to ensure that each product meets the rigorous demands of modern surgery. From material selection to manufacturing processes, from functional design to user experience, we strive for perfection, providing medical professionals with reliable surgical tools.

For trocar maintenance, detachable components should be disassembled and thoroughly cleaned immediately after surgery. Soaking in a multi-enzyme detergent combined with ultrasonic cleaning can effectively remove residual debris within the lumen. Pay special attention to inspecting the sharpness and integrity of the trocar tip. This can be verified using a magnifying glass or a gauze scrape test. A leak-tightness test should also be performed to ensure the interface is leak-free. Choose the appropriate sterilization method based on the material: high-temperature resistant components should be sterilized with high-pressure steam, while precision components should be sterilized with low-temperature plasma. Store the trocar dry and avoid deformation. Obstructions should be gently removed using a dedicated sterilizer. Valve malfunction can be resolved with silicone oil lubrication or component replacement. Surgical stapler maintenance requires a rigorous, phased cleaning process, from rapid postoperative pre-cleaning to deep cleaning. Using a neutral pH detergent and ultrasonic vibration can effectively remove tissue debris. Focus on maintaining key components, such as the firing mechanism and stapler cartridge slot. Regularly apply medical-grade grease to keep the mechanical components operating smoothly.

Maintenance of the ligature system focuses on electrode care and energy calibration. Electrodes should be cleaned promptly after surgery, and stubborn eschars should be removed with specialized abrasive tools. Regular power calibration and footswitch inspection are essential for maintaining device performance, and meticulous cable management is crucial for ensuring signal transmission. Verifying closure strength through simulated tissue testing is a reliable method for assessing device status. A comprehensive maintenance record should be maintained for all devices, documenting sterilization cycles and repair history, and regular professional training should be provided to operators.

English

English Español

Español Français

Français

CONTACT US

CONTACT US