With a building area of 20,310 square metres, the company has a class 100,000 purified production workshop, a class 10,000 microbiology testing room, a local class 100 physical and chemical laboratory, and a standardised storage system for raw materials and finished products.

Since the initial batch of products were launched in 2013, Eray has continuously enriched its product categories. Our products have covered protective masks, nursing consumables, sensory control consumables, surgical instruments, providing safe, efficient and environmentally friendly disposable medical solutions for medical institutions worldwide.

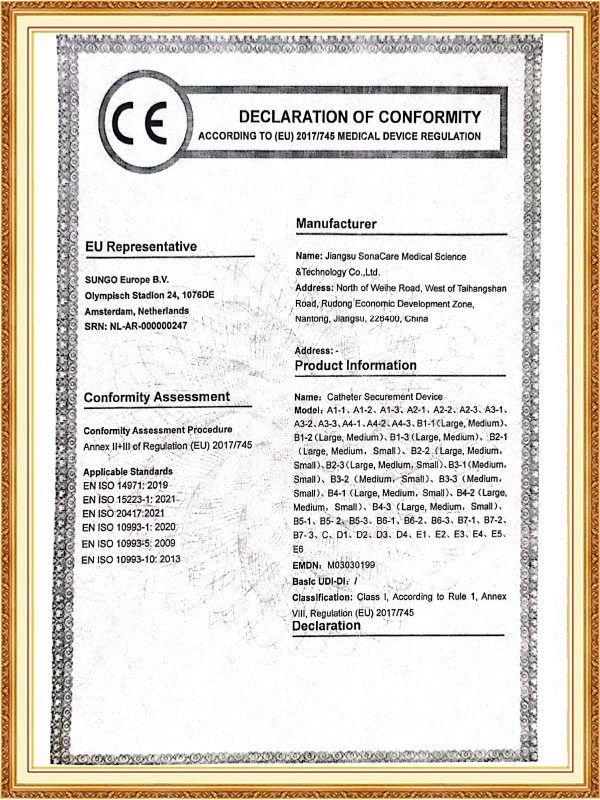

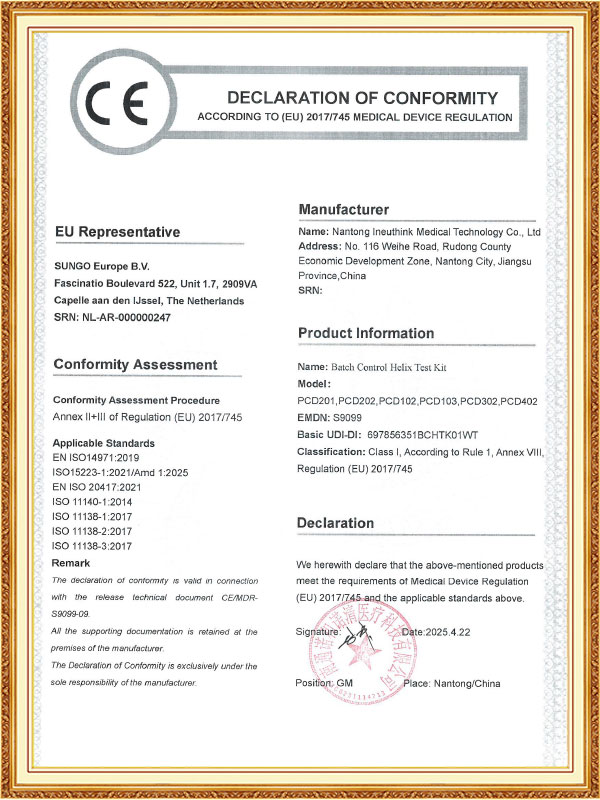

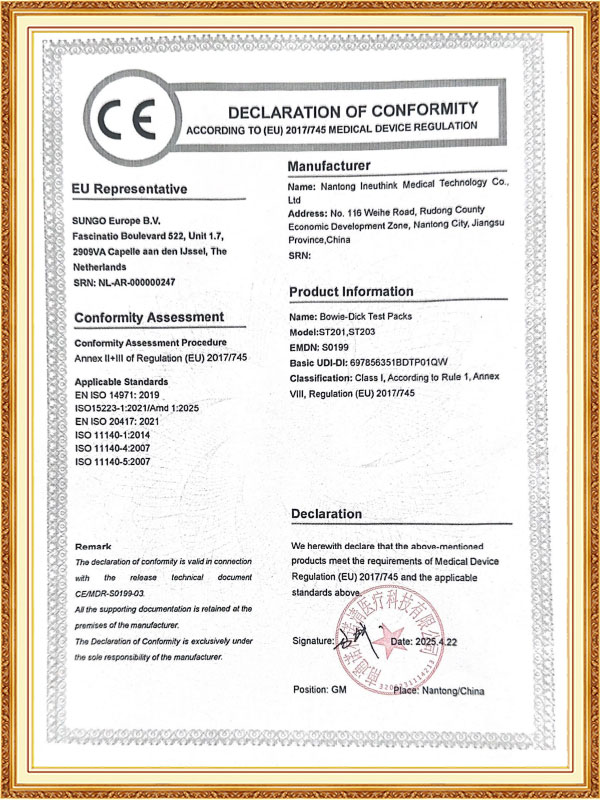

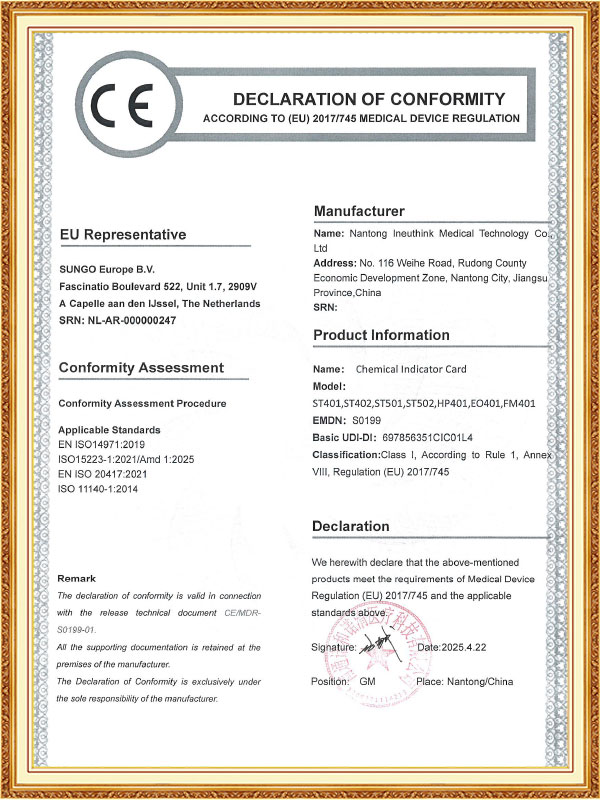

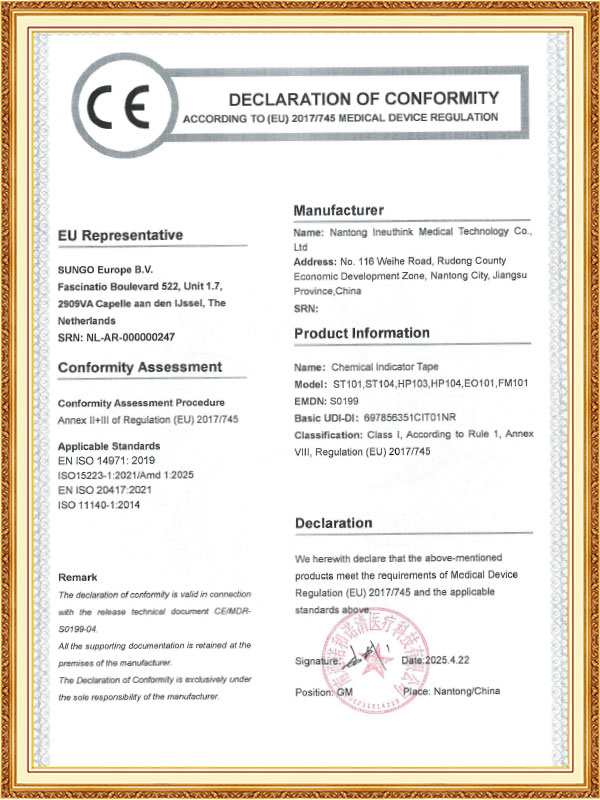

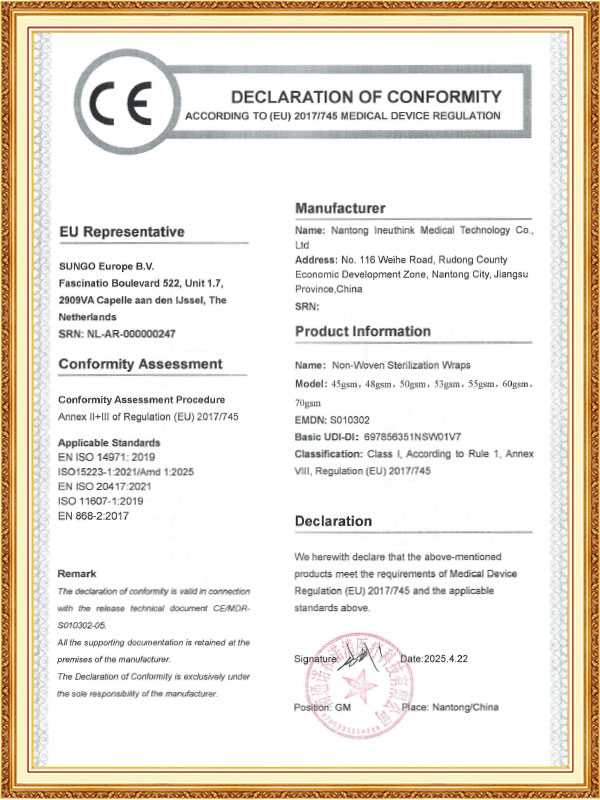

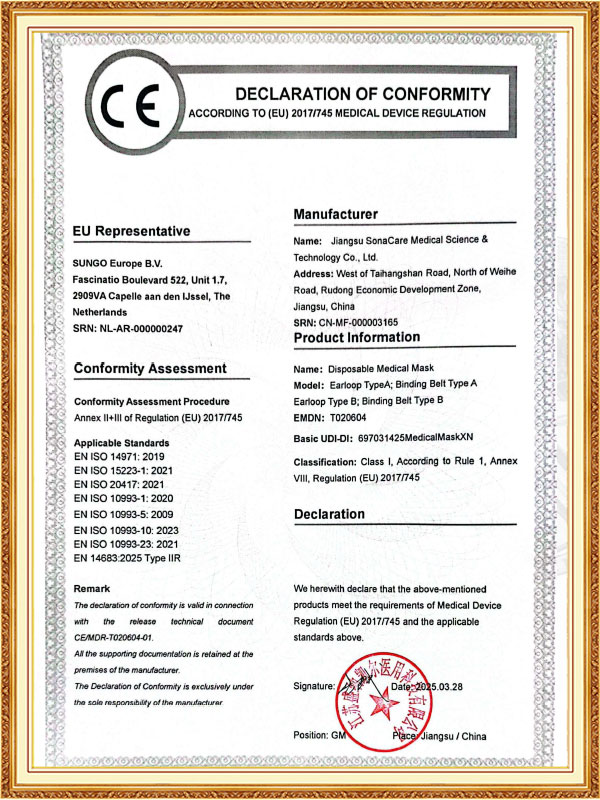

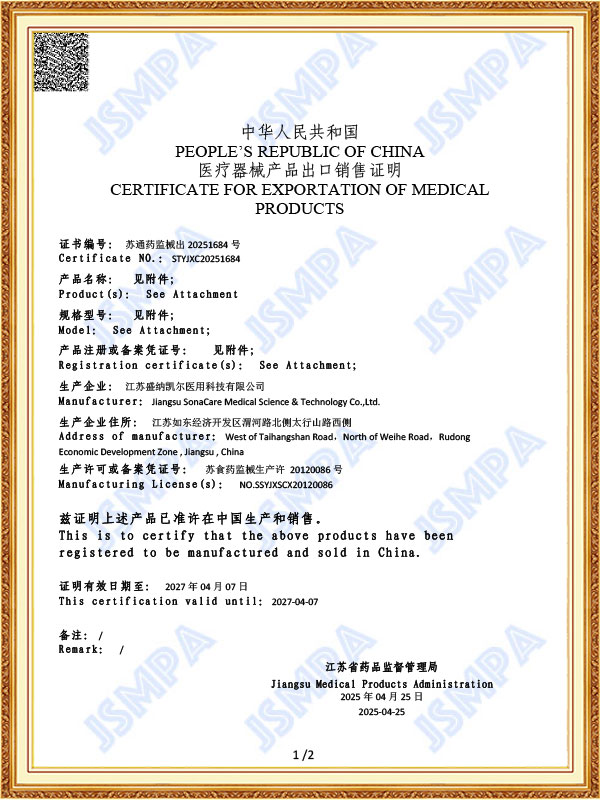

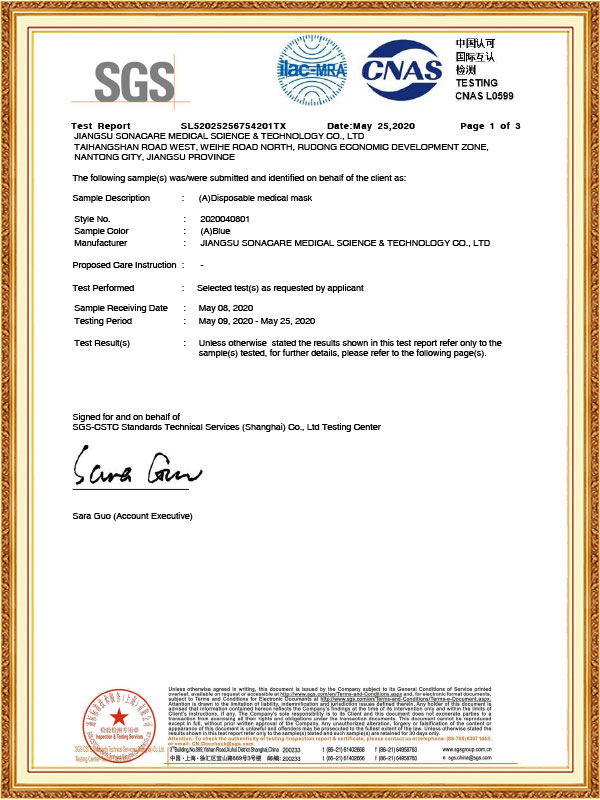

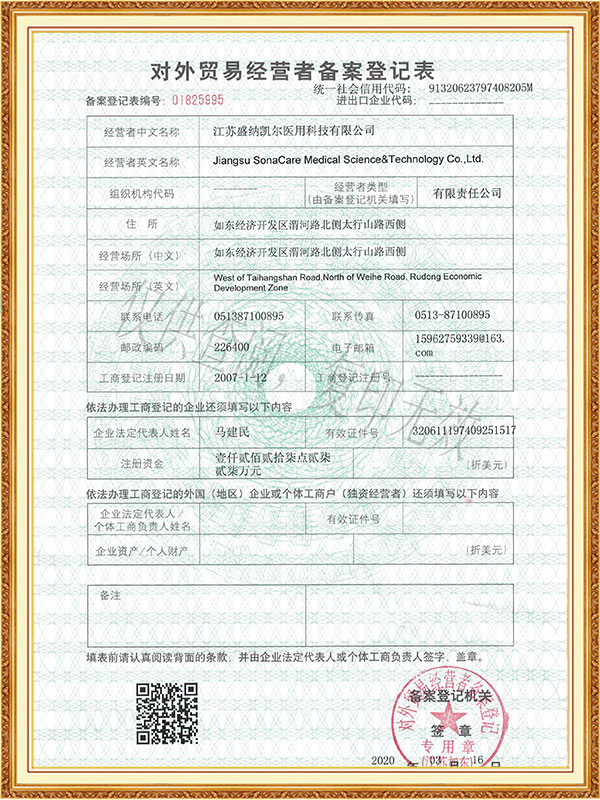

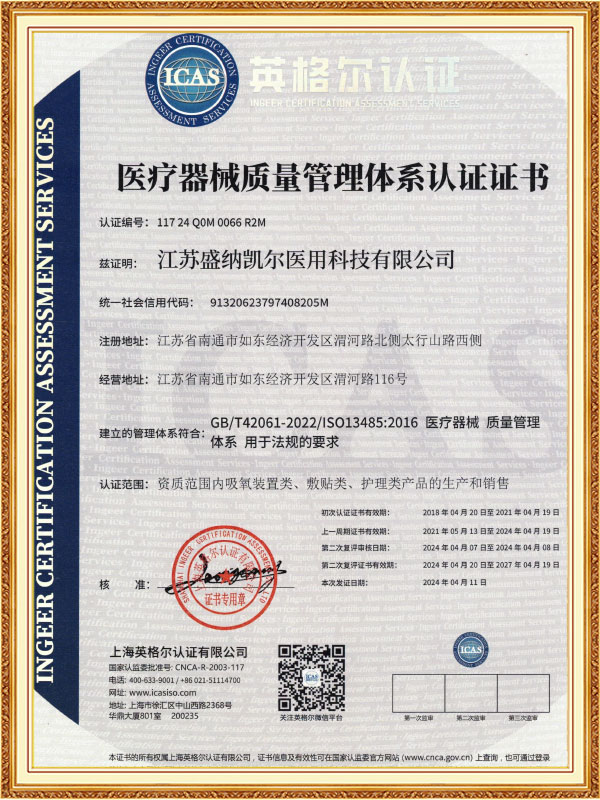

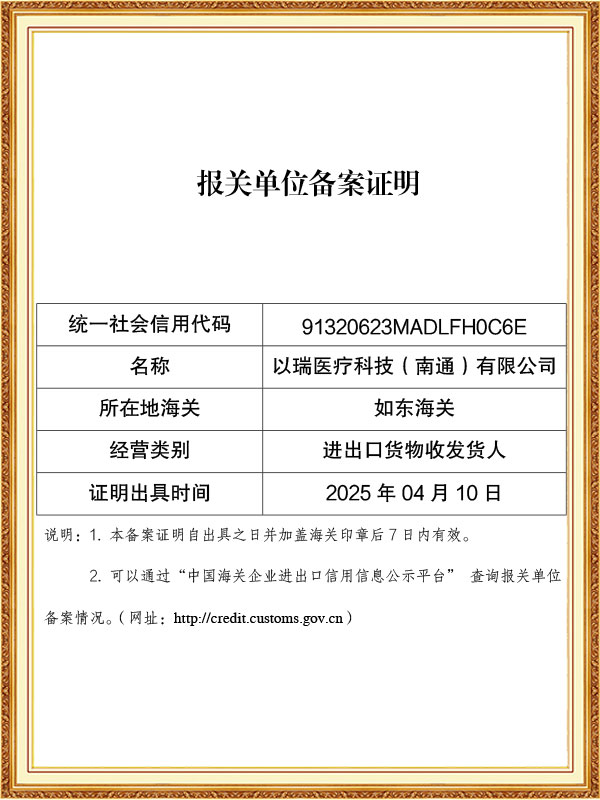

As a professional OEM Vacuum Boiling Washer Manufacturers and ODM Vacuum Boiling Washer Factory, The company has passed ISO 13485 and other quality system certifications, and some of its products have obtained CE certification and FDA filing permits, and has established long-term cooperative relationships with many domestic and foreign medical institutions and distributors.

-

Feb 27. 2026

Can Optical Trocars Reduce the Risk of Organ Injury?Optical Trocars Significantly Reduce Organ Injury Risk Yes, optical trocars can significantly reduce the risk of organ injury during laparoscopic surgery by allowing surgeons to visualize tissue layers in real time as the instrument passes through the abdominal wall. Unlike blin...

Read More -

Feb 20. 2026

What is an Optical Trocar and Why is it Essential in Medical Procedures?What is an Optical Trocar and Why is it Essential in Medical Procedures? An optical trocar is a specialized surgical instrument used primarily in minimally invasive procedures. It combines the functions of a trocar and a visual scope, allowing surgeons to create an access point ...

Read More -

Feb 13. 2026

What Are the Common Problems With Medical Trocars and How to Avoid Them?What Are the Most Common Problems With Medical Trocars? The most common problems with medical trocars include insertion injuries, gas leakage, dull blades, instability, and contamination risks. These issues can compromise surgical safety, increase operating time, and raise posto...

Read More

In the medical field, traditional washing methods struggle to achieve both thorough cleaning and effective sterilization, while high-temperature sterilization can easily damage fabric fibers. The advent of medical vacuum boiling washing machines offers an innovative solution to this problem. These washing machines utilize advanced low-pressure boiling technology. A precision vacuum system reduces the pressure within the washing chamber to a specific level, allowing the water to boil at temperatures as low as 50-60°C. This unique physical process produces a dual cleaning effect: Firstly, micron-sized bubbles formed by the boiling water flow vigorously move between textile fibers, generating a powerful cavitation effect that deeply dissolves various organic stains. Secondly, the continuous boiling state itself is a highly effective physical sterilization process, effectively killing a wide range of pathogens, including drug-resistant bacteria.

Clinical testing has shown that at an operating temperature of 55°C, the device can achieve a 99.99% kill rate against common hospital-acquired bacteria, such as Staphylococcus aureus and Escherichia coli, fully meeting medical hygiene standards. Compared to traditional high-temperature sterilization, this low-temperature sterilization method significantly reduces heat damage to medical textiles such as surgical drapes and isolation gowns, extending their lifespan and significantly saving medical institutions on consumables. In practical applications, this device is particularly suitable for processing high-risk textiles such as operating room linens and intensive care unit bedding. Its intelligent control system can store multiple specialized wash programs, automatically adjusting the vacuum level, water temperature, and treatment time for medical textiles of varying risk levels. A built-in turbidity sensor monitors wash results in real time, ensuring that each batch meets the required hygiene standards.

With the continuous improvement of hospital infection control standards and the advancement of green hospital construction, medical vacuum boiling washing machines are gaining increasing recognition worldwide. More than just a washing machine, they are a crucial component of hospital infection control systems. Through technological innovation, they achieve an optimal balance between cleaning effectiveness, sterilization reliability, and resource conservation. As medical quality requirements continue to rise, this technological innovation, which integrates physical principles with medical needs, will make a greater contribution to ensuring patient safety and improving the quality of medical services.

Maintenance and management of medical vacuum boiling washing machines is crucial for ensuring the quality of medical device cleaning, and a systematic maintenance process is essential. After daily use, drain the chamber immediately. Thoroughly wipe the interior walls, door seals, and observation windows with a neutral detergent, paying special attention to removing residual stains and scale. The spray system is a key maintenance priority. Regularly check the spray holes for blockage and ensure smooth rotation. Clean the filters at the water inlet and outlet to maintain unimpeded water flow. Water quality management is crucial. Use purified or deionized water with a conductivity of ≤15μS/cm. Regularly test the water treatment system's performance and replace filters promptly.

A deep maintenance should be performed monthly. Use a dedicated descaling agent to thoroughly clean areas prone to scale accumulation, such as heating elements and piping. Afterward, rinse repeatedly with pure water to eliminate chemical residue. Vacuum system maintenance is essential. Check the vacuum pump oil level and replace it promptly every quarter. Perform a leak test to ensure stable vacuum levels. Maintenance of mechanical parts is equally important. Door seals need to be coated with medical silicone oil every month to prevent aging. Moving parts such as slide rails and hinges need to be regularly inspected and food-grade grease added. Key sensors such as temperature and pressure need to be calibrated every six months to ensure that the measurement data is accurate and reliable. Before the equipment is out of use for a long time, all water tanks and pipes must be emptied and dust-proofed. A no-load test must be performed before reactivation. It is crucial to establish a complete maintenance file, and detailed records must be kept of each cleaning, calibration, and repair. At the same time, operators should receive regular professional training so that they can master the correct usage methods and basic troubleshooting skills. Through standardized maintenance management, not only can the service life of the equipment be extended by 3-5 years, but it can also ensure the continuous provision of safe and reliable cleaning services, providing a solid guarantee for medical quality and safety. In case of complex faults, professional maintenance personnel should be contacted in a timely manner to avoid secondary damage caused by self-disassembly.

English

English Español

Español Français

Français

CONTACT US

CONTACT US