Eray MedTech sterile processing solution includes CSSD equipment and sterilization indicators

Eray MedTech Sterile Processing Solution is a comprehensive medical equipment and device management solution designed to ensure that the cleaning, disinfection and sterilization processes of medical devices meet international standards, thereby ensuring patient safety and reducing the risk of nosocomial infections.

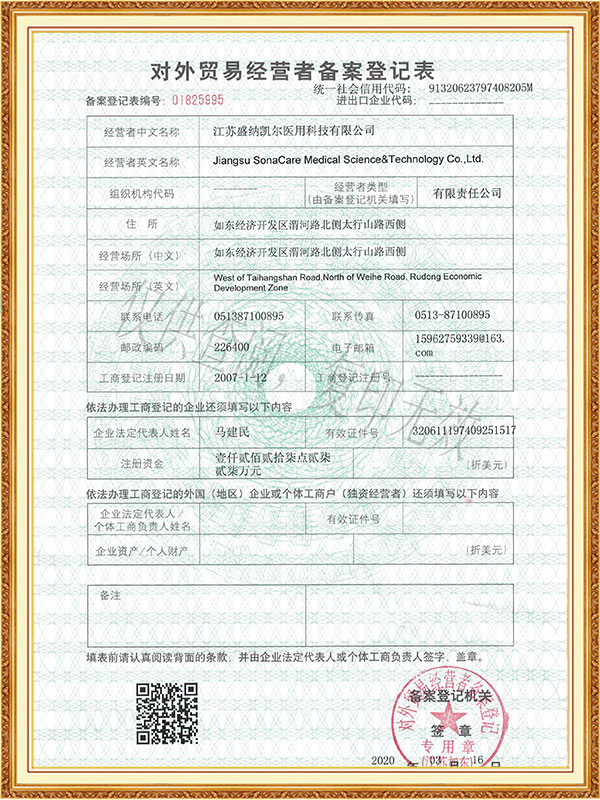

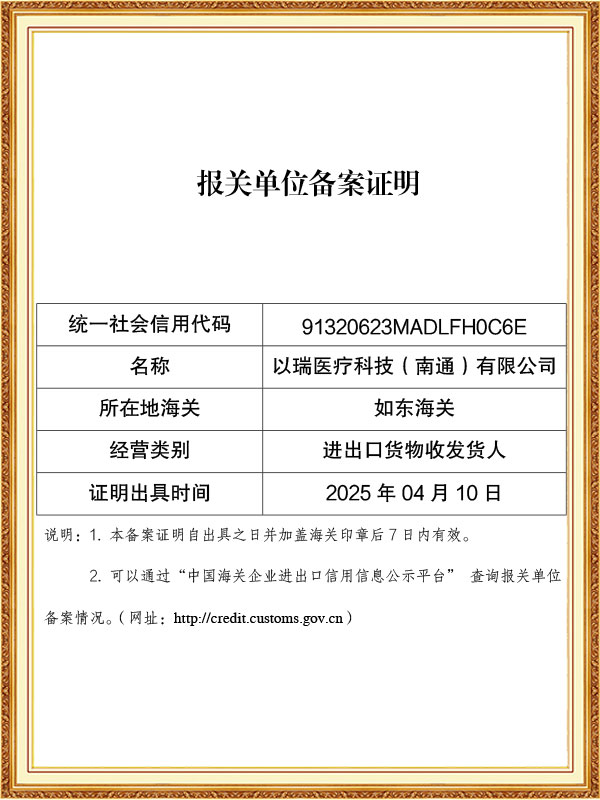

Eray Medical Technology (Nantong) Co., Ltd, focusing on the field of medical devices, is an integrated enterprise of industry and trade integrating R&D, production and sales. The company's manufacturing base is located in Rudong Economic Development Zone in Jiangsu Province, which has a favourable geographical location, convenient traffic and a good supporting environment for industrial clusters.

With a building area of 20,310 square metres, the company has a class 100,000 purified production workshop, a class 10,000 microbiology testing room, a local class 100 physical and chemical laboratory, and a standardised storage system for raw materials and finished products.

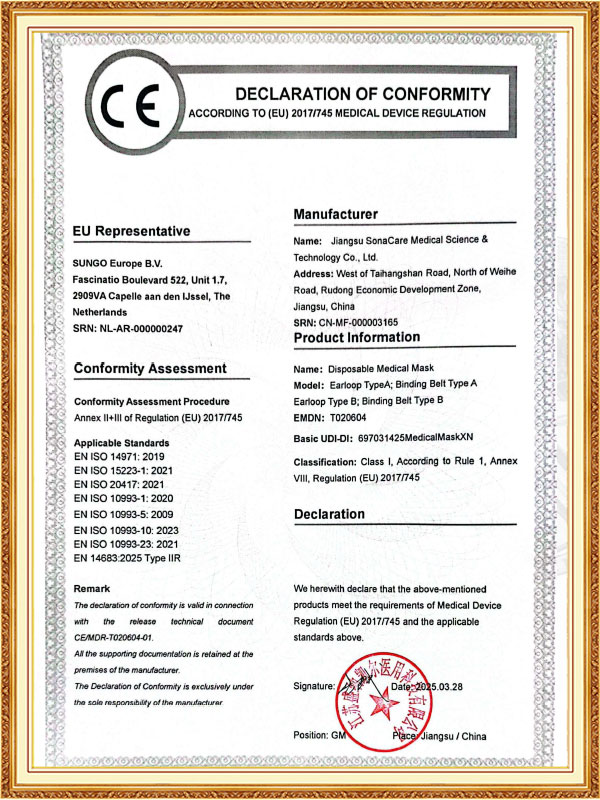

Since the initial batch of products were launched in 2013, Eray has continuously enriched its product categories. Our products have covered protective masks, nursing consumables, sensory control consumables, surgical instruments, providing safe, efficient and environmentally friendly disposable medical solutions for medical institutions worldwide.

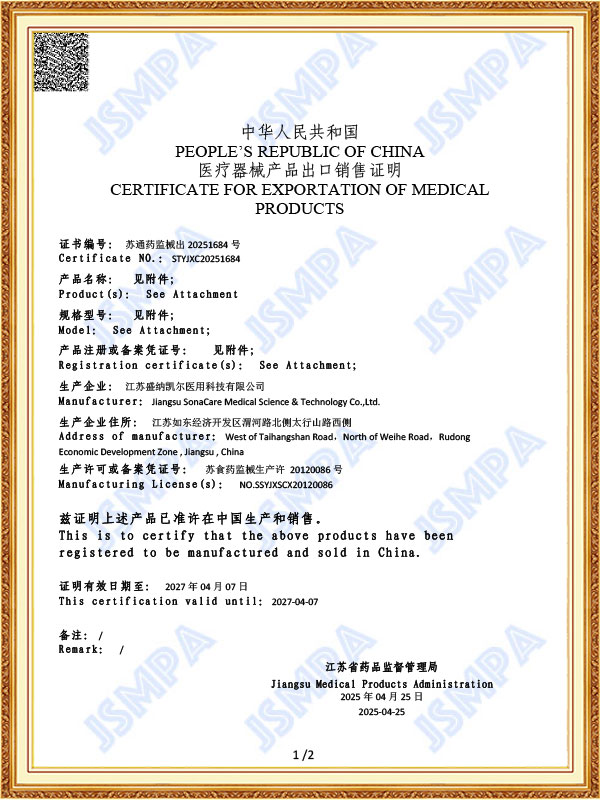

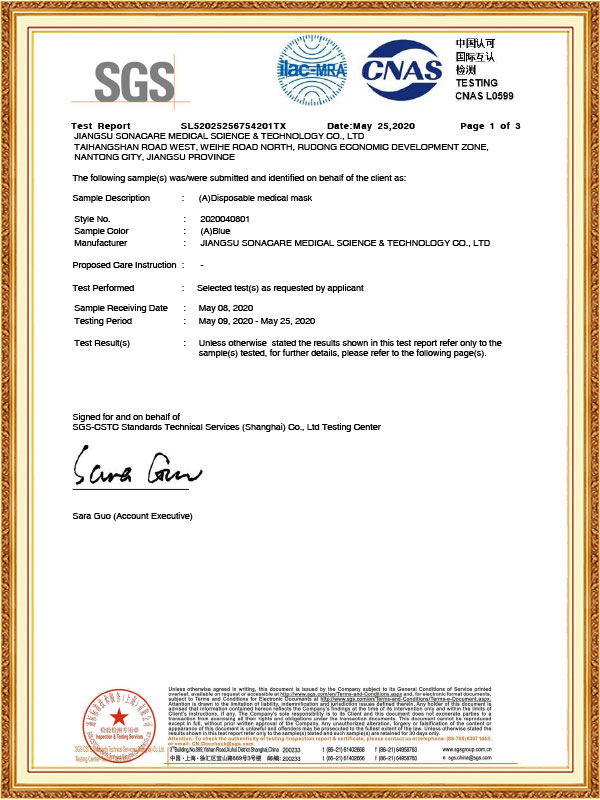

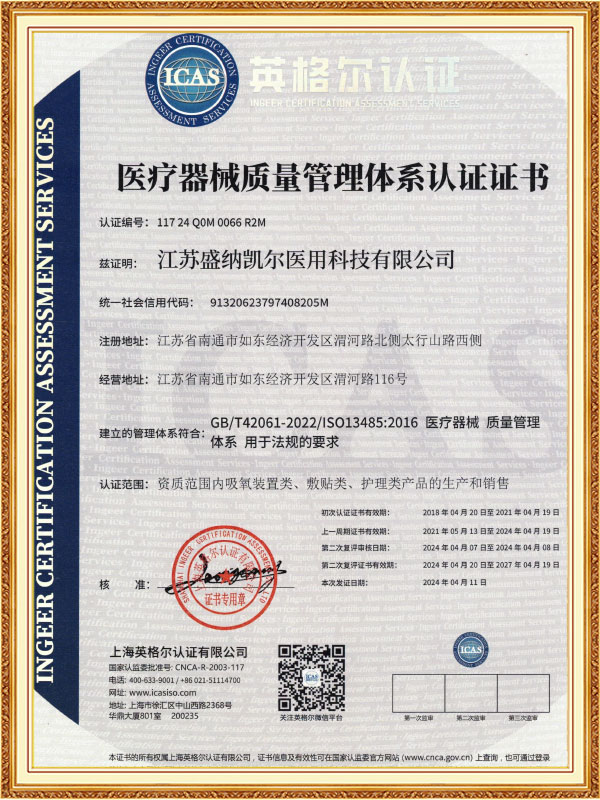

The company has passed ISO 13485 and other quality system certifications, and some of its products have obtained CE certification and FDA filing permits, and has established long-term cooperative relationships with many domestic and foreign medical institutions and distributors.

-

Feb 27. 2026

Can Optical Trocars Reduce the Risk of Organ Injury?Optical Trocars Significantly Reduce Organ Injury Risk Yes, optical trocars can significantly reduce the risk of organ injury during laparoscopic surgery by allowing surgeons to visualize tissue layers in real time as t...

Read More -

Feb 20. 2026

What is an Optical Trocar and Why is it Essential in Medical Procedures?What is an Optical Trocar and Why is it Essential in Medical Procedures? An optical trocar is a specialized surgical instrument used primarily in minimally invasive procedures. It combines the functions of a trocar and ...

Read More -

Feb 13. 2026

What Are the Common Problems With Medical Trocars and How to Avoid Them?What Are the Most Common Problems With Medical Trocars? The most common problems with medical trocars include insertion injuries, gas leakage, dull blades, instability, and contamination risks. These issues can compromi...

Read More

In modern healthcare, thorough cleaning and effective sterilization of medical devices are crucial for ensuring patient safety and reducing the risk of nosocomial infections. Leveraging advanced medical technology, Eray MedTech offers a comprehensive suite of sterile processing solutions. Through intelligent CSSD equipment and precise sterilization indicators, Eray MedTech provides medical institutions with a device management solution that complies with international standards, ensuring that every medical supply is reliably sterile.

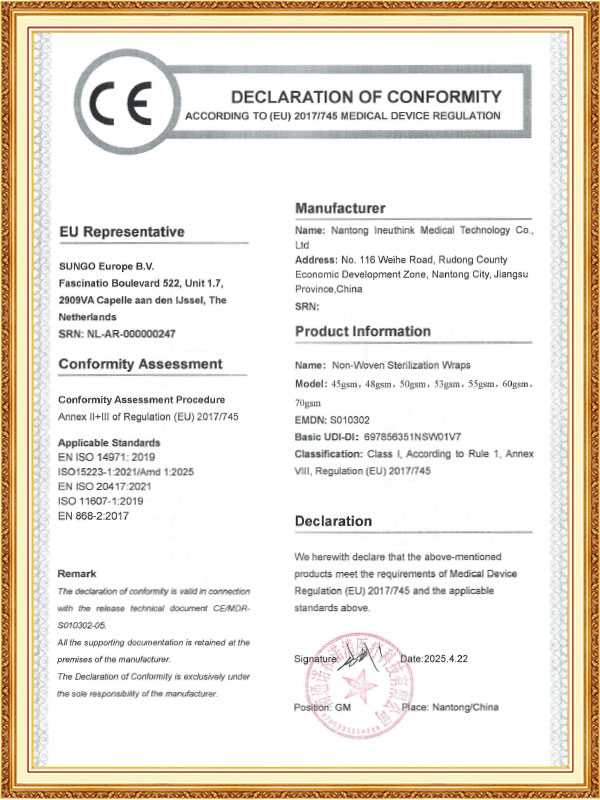

Eray MedTech's CSSD equipment is designed for modern sterilization supply centers and covers the entire process from device recovery to sterilization. The highly efficient cleaning and disinfection equipment utilizes spray cleaning and ultrasonic technology to thoroughly remove residual blood, tissue, and microorganisms from device surfaces, enabling deep cleaning of even complex endoscopes. Fully automated washer-disinfectors combine high-temperature water washing with chemical disinfection to ensure optimal cleaning results for devices of varying materials. For sterilization, the intelligent steam sterilizer utilizes high-pressure saturated steam to achieve high-temperature sterilization at 134°C, fully complying with international standards such as EN 285 and AAMI ST79. Its vacuum drying function also prevents secondary contamination of devices. For linens such as surgical gowns and drapes, vacuum-boiling washing machines utilize unique vacuum-boiling technology to improve cleaning efficiency, ensuring sterility and residue-free fabrics, providing an additional layer of assurance for surgical safety.

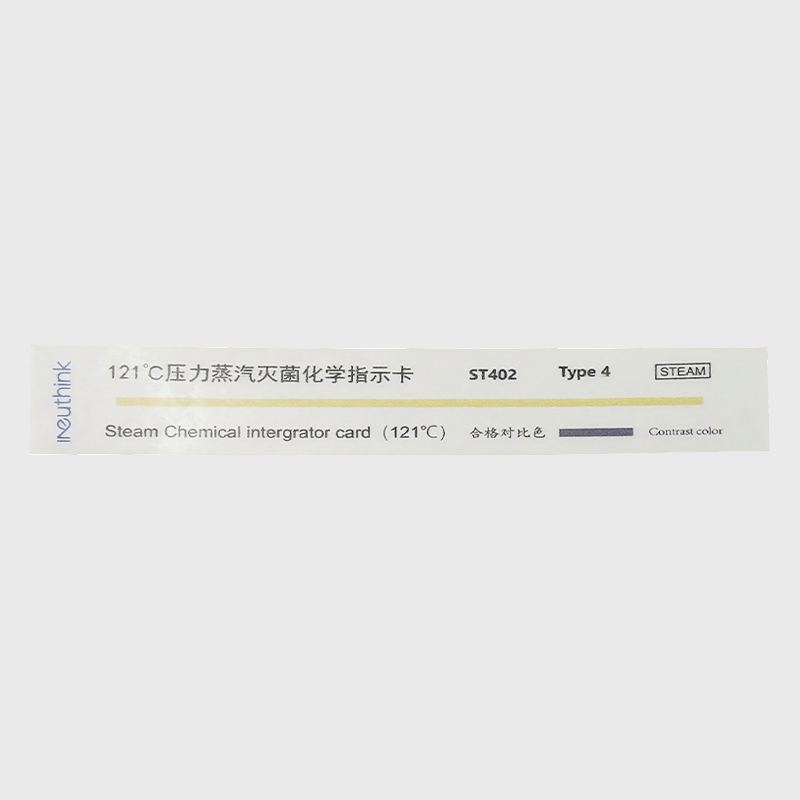

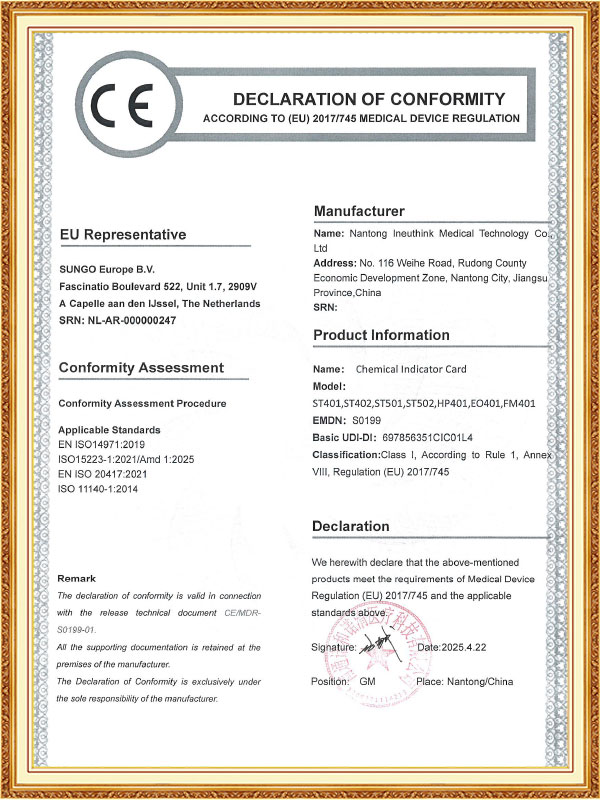

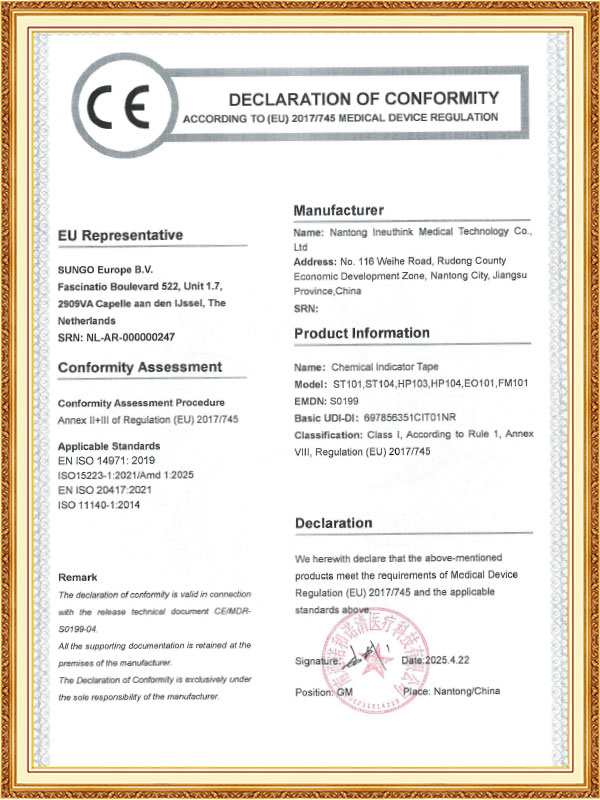

Monitoring the effectiveness of the sterilization process is equally crucial, and Eray MedTech's sterilization indicators provide a precise solution. Chemical indicators, including in-package indicator cards and adhesive tape, provide intuitive color changes to help medical staff quickly determine whether sterilization has met specifications. They are compatible with various sterilization methods, including steam and ethylene oxide. Furthermore, electronic monitoring systems record key parameters such as temperature, pressure, and time in real time, generating traceable data reports that meet international standards such as ISO 11140 and AAMI ST79, making sterilization management more transparent and reliable.

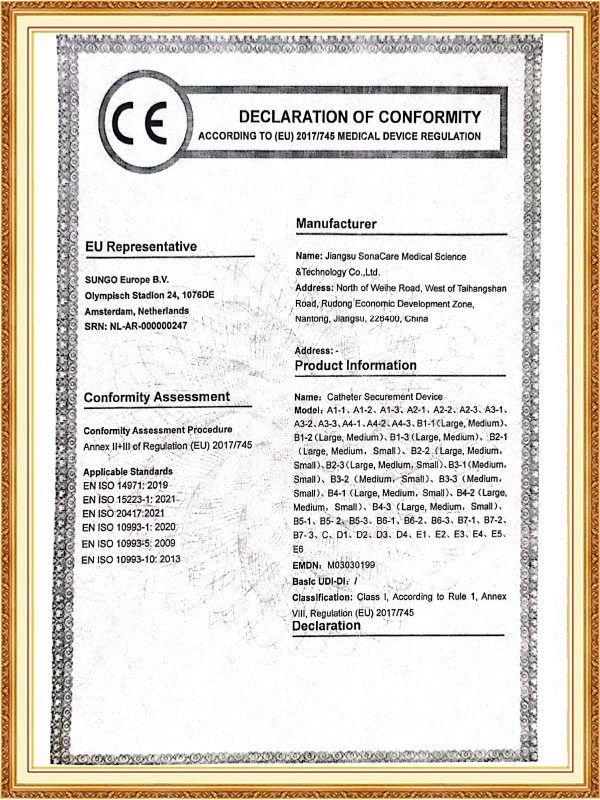

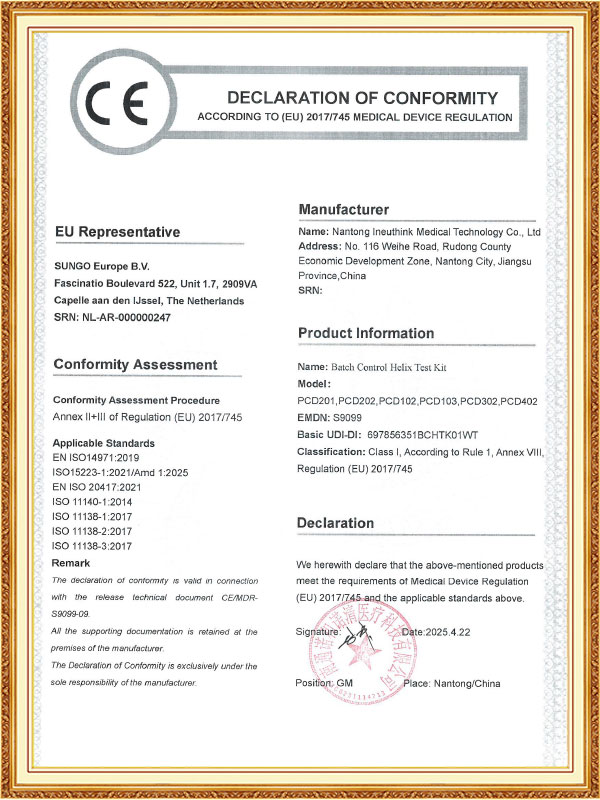

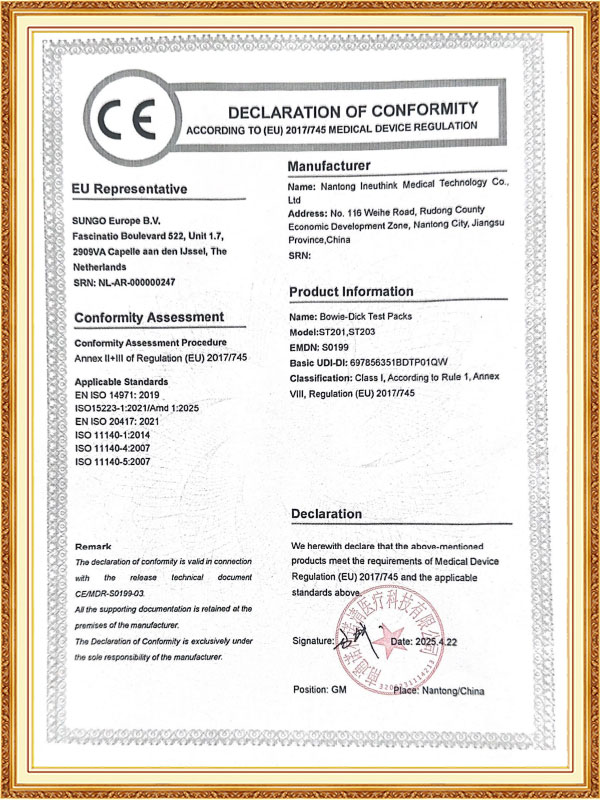

The core advantage of Eray MedTech's sterile processing solutions lies in their strict adherence to international standards. All equipment and consumables are CE, FDA, and ISO certified, ensuring compliance with global medical institutions. The introduction of an intelligent management system further optimizes the sterilization process and improves operational efficiency through data traceability and cloud-based storage. Eray MedTech also provides professional technical training and customized services to help medical institutions establish efficient and safe aseptic processing systems.

With healthcare safety increasingly a priority, Eray MedTech empowers aseptic processing with innovative technologies, striving for precision and reliability in every step, from instrument cleaning to sterilization verification. This solution not only reduces the risk of hospital-acquired infections but also improves overall healthcare quality, providing a solid foundation for patient safety and care. Through continuous technological upgrades and service optimization, Eray MedTech is helping medical institutions around the world move towards a new era of higher standards in aseptic management.

English

English Español

Español Français

Français

CONTACT US

CONTACT US