Laboratory Glassware Washer Suppliers

information to be updated

With a building area of 20,310 square metres, the company has a class 100,000 purified production workshop, a class 10,000 microbiology testing room, a local class 100 physical and chemical laboratory, and a standardised storage system for raw materials and finished products.

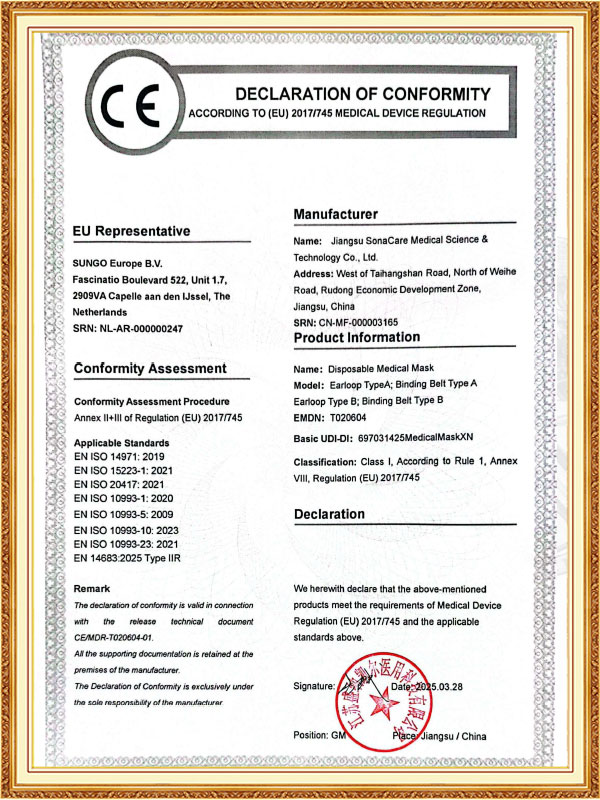

Since the initial batch of products were launched in 2013, Eray has continuously enriched its product categories. Our products have covered protective masks, nursing consumables, sensory control consumables, surgical instruments, providing safe, efficient and environmentally friendly disposable medical solutions for medical institutions worldwide.

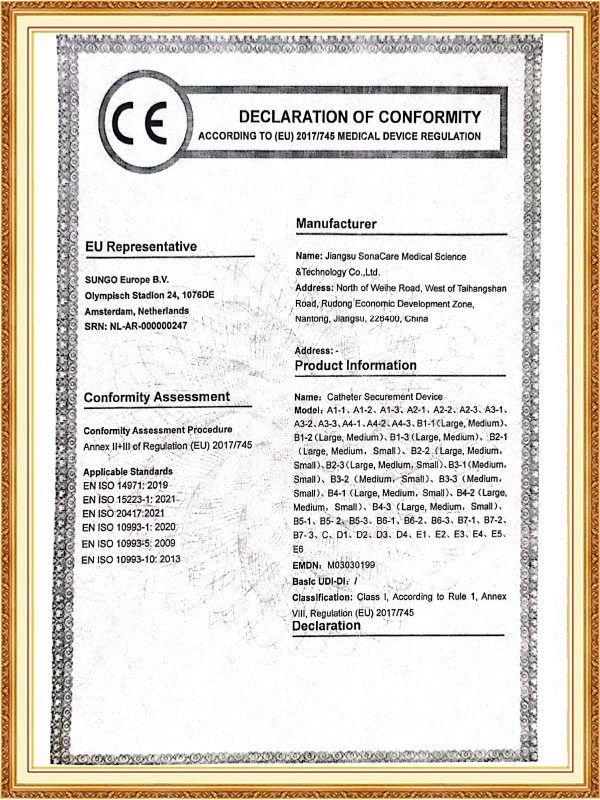

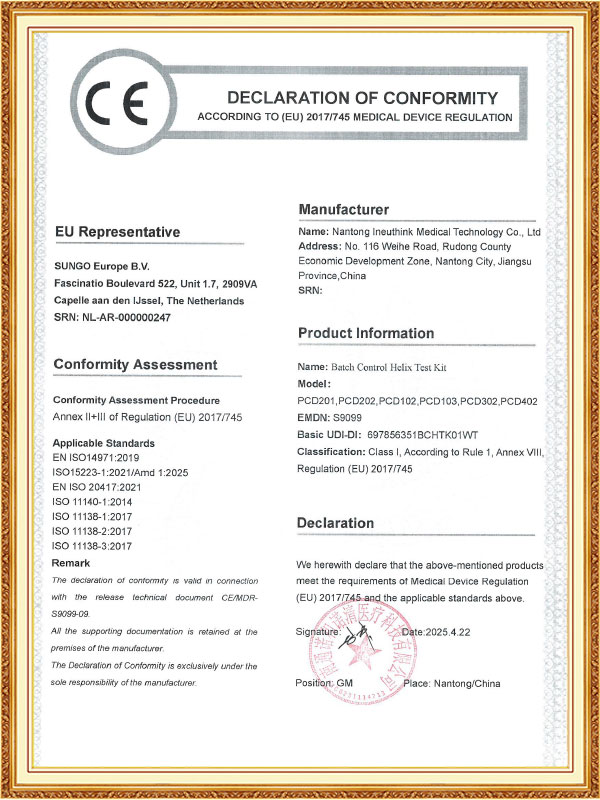

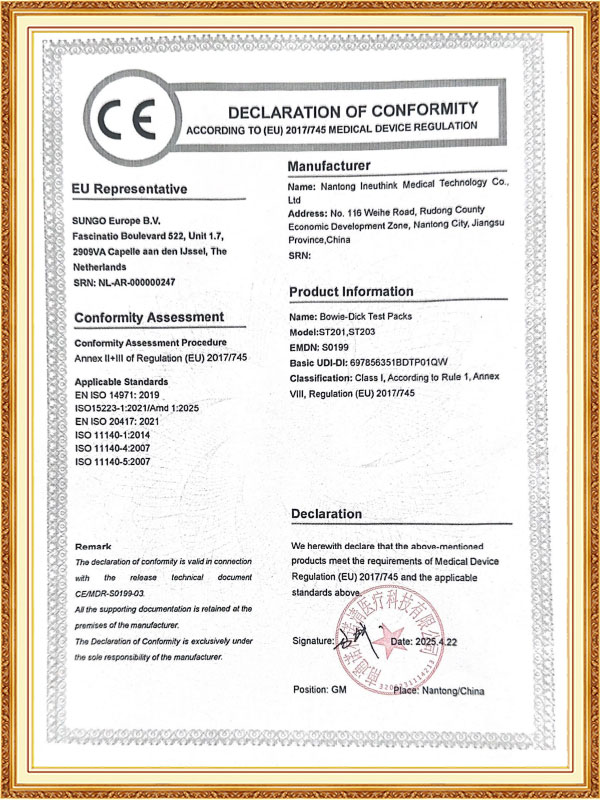

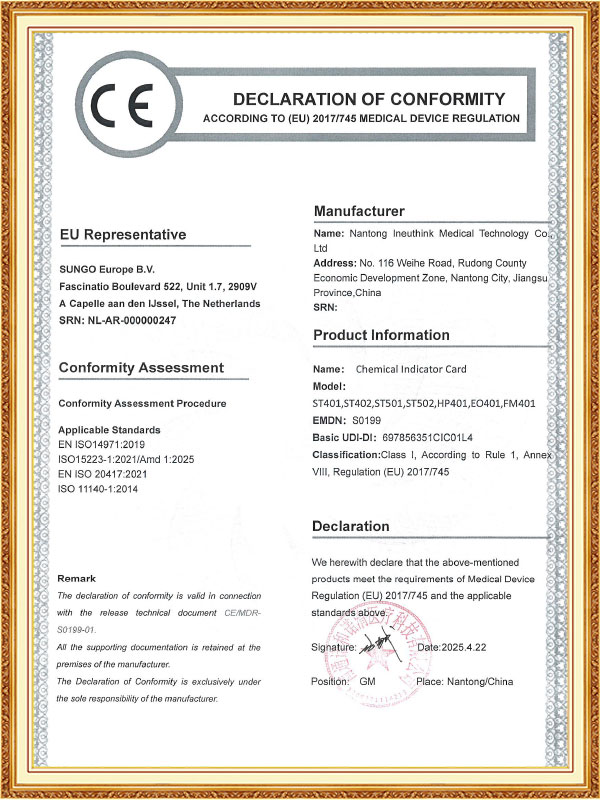

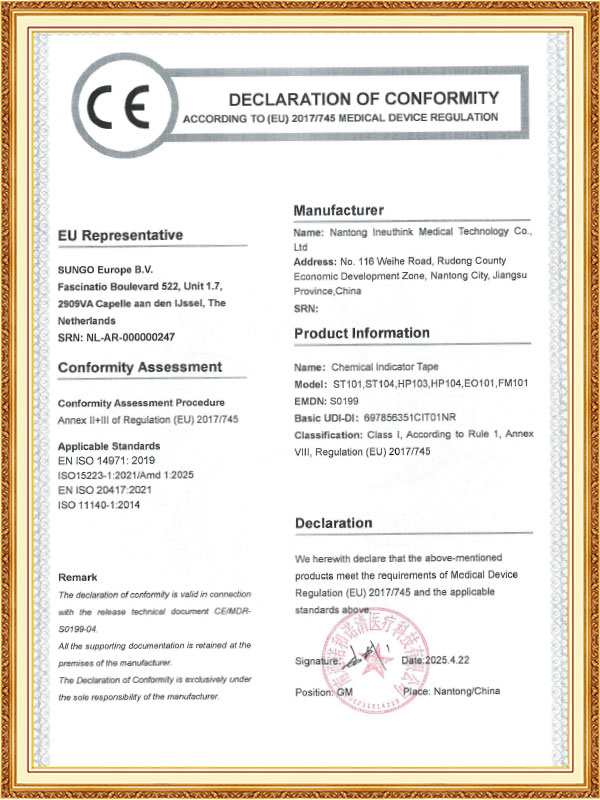

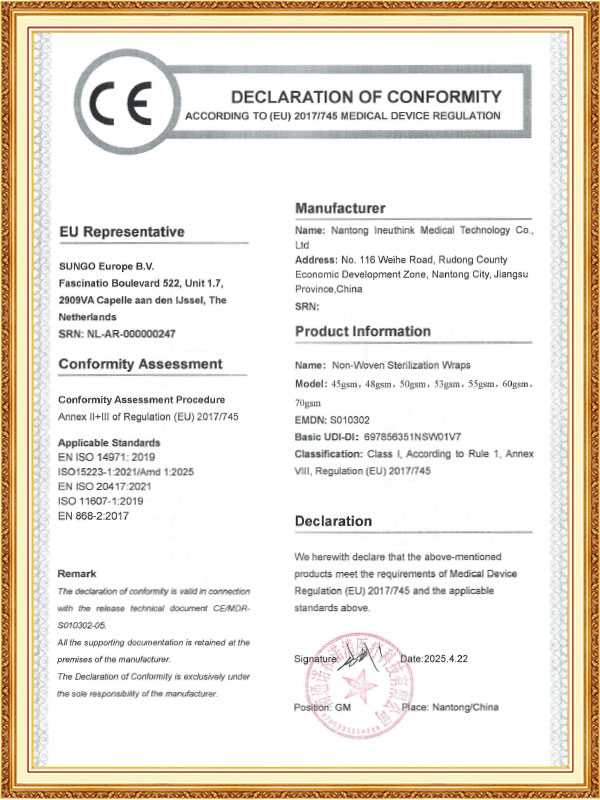

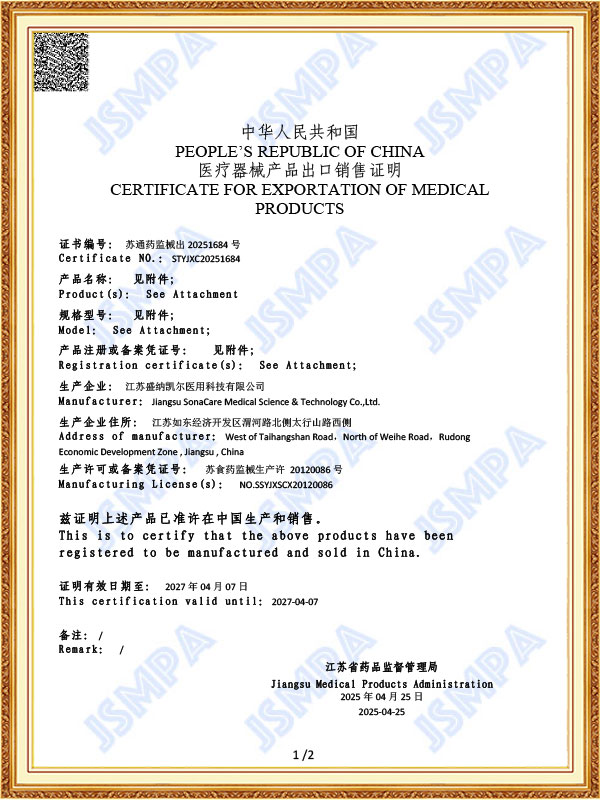

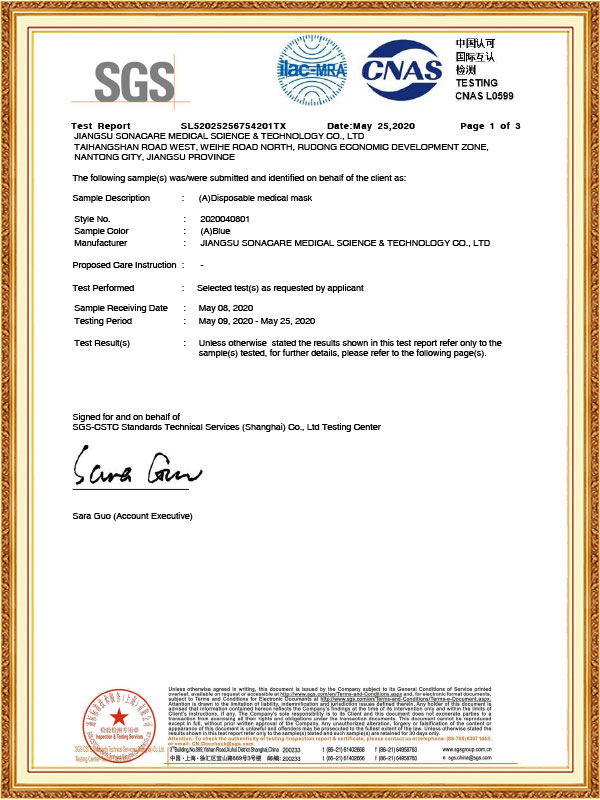

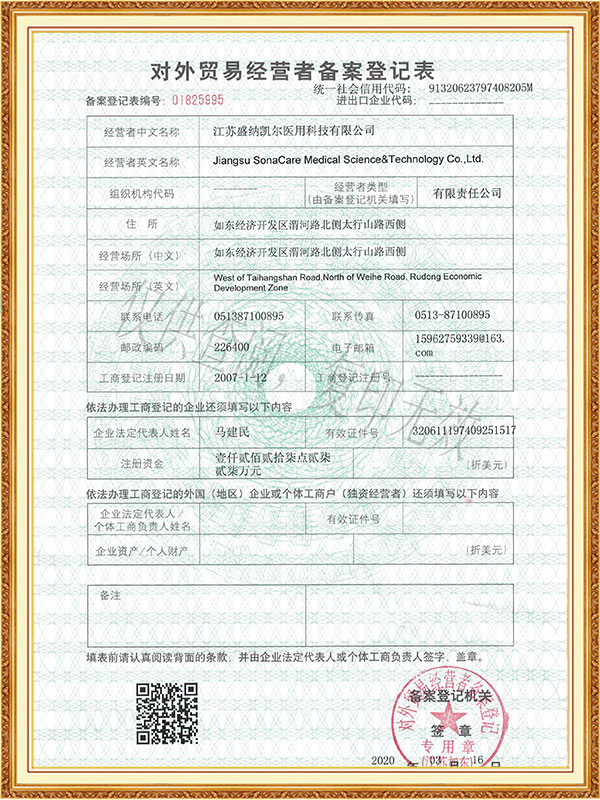

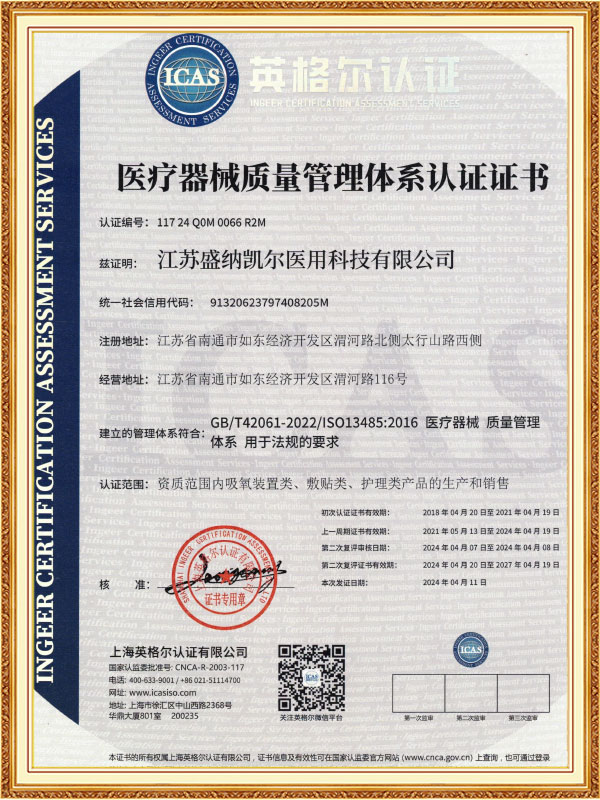

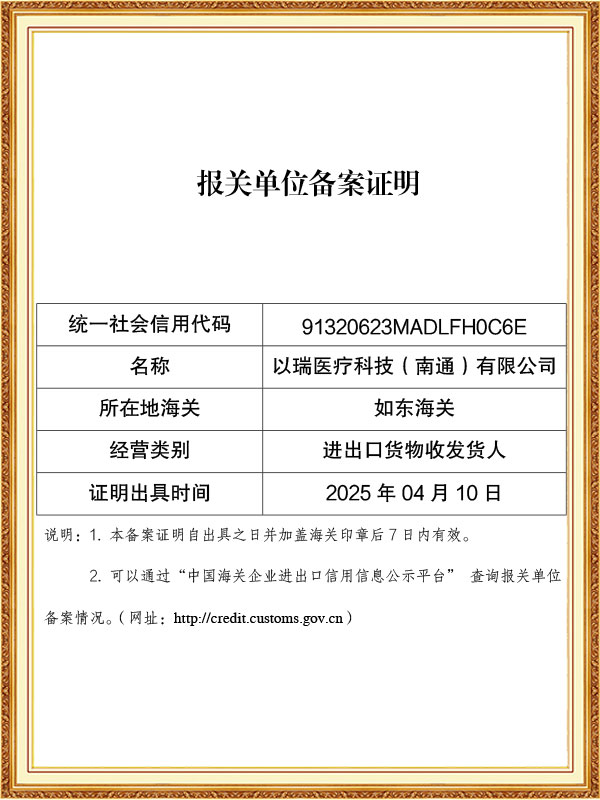

As a professional OEM Laboratory Glassware Washer Suppliers and ODM Laboratory Glassware Washer Factory, The company has passed ISO 13485 and other quality system certifications, and some of its products have obtained CE certification and FDA filing permits, and has established long-term cooperative relationships with many domestic and foreign medical institutions and distributors.

-

Feb 27. 2026

Can Optical Trocars Reduce the Risk of Organ Injury?Optical Trocars Significantly Reduce Organ Injury Risk Yes, optical trocars can significantly reduce the risk of organ injury during laparoscopic surgery by allowing surgeons to visualize tissue layers in real time as the instrument passes through the abdominal wall. Unlike blin...

Read More -

Feb 20. 2026

What is an Optical Trocar and Why is it Essential in Medical Procedures?What is an Optical Trocar and Why is it Essential in Medical Procedures? An optical trocar is a specialized surgical instrument used primarily in minimally invasive procedures. It combines the functions of a trocar and a visual scope, allowing surgeons to create an access point ...

Read More -

Feb 13. 2026

What Are the Common Problems With Medical Trocars and How to Avoid Them?What Are the Most Common Problems With Medical Trocars? The most common problems with medical trocars include insertion injuries, gas leakage, dull blades, instability, and contamination risks. These issues can compromise surgical safety, increase operating time, and raise posto...

Read More

In scientific research laboratories, the accuracy and reproducibility of experimental data are crucial, and the cleanliness of glassware directly impacts experimental results. Traditional manual cleaning methods are not only inefficient but also difficult to ensure consistent cleanliness across every piece of glassware, easily introducing human error. The advent of laboratory glassware washers has revolutionized this situation. Through automated, standardized cleaning processes, they ensure that every piece of glassware meets the required cleanliness standards for experiments.

Laboratory glassware washers go far beyond simple cleaning. They efficiently remove chemical residues, biological stains, grease, and particulate contaminants from glassware, ensuring that subsequent experiments are not disrupted. Whether it's standard beakers and Erlenmeyer flasks, or delicate chromatography vials, pipettes, or even complex condensers, these washers thoroughly clean every detail with optimized water flow and cleaning procedures. Furthermore, some high-end models feature high-temperature sterilization or drying capabilities, further meeting the stringent sterile environment requirements of biological laboratories and the pharmaceutical industry.

In terms of product features, laboratory glassware washers incorporate multiple advanced technologies to meet diverse experimental needs. First, its interior is constructed of corrosion-resistant stainless steel or a special polymer material, resistant to strong acids, bases, and organic solvents, ensuring long-term stable operation. Second, its intelligent control system allows users to customize cleaning parameters, such as water temperature, cleaning time, and number of rinses, to accommodate vessels with varying degrees of contamination. For example, a high-temperature alkaline cleaning program can be set for stubborn organic residues, while multiple rinses with ultrapure water can be used for trace analysis experiments to prevent ionic contamination. Furthermore, the modular design of the cleaning basket allows for flexible adjustment to accommodate vessels of varying shapes and sizes, improving cleaning efficiency.

Laboratory glassware washers not only improve cleaning efficiency but also reduce labor intensity for laboratory personnel. Traditional manual cleaning is time-consuming and labor-intensive, and can easily lead to breakage due to improper operation. Automated cleaning, on the other hand, can process large batches of glassware in a short period of time while reducing human error. Furthermore, the standardized operation of the washing machine ensures traceability of cleaning parameters for each batch, providing reliable support for laboratory quality management systems such as GLP and GMP.

Proper maintenance of laboratory glassware washers is crucial for ensuring accurate experimental data and long-term stable operation. After daily use, drain any accumulated water promptly. Thoroughly wipe the wash chamber walls, spray arms, and instrument baskets with a soft cloth dampened with neutral detergent, paying particular attention to removing residual chemicals and scale deposits. Maintaining the spray system is particularly critical. Regularly check the spray holes for blockage and ensure smooth rotation. Clean the filters at the water inlet and outlet to maintain optimal water flow. Water quality directly impacts cleaning results. Use purified water with a conductivity of ≤15μS/cm. Regularly test the water treatment system's performance and replace the activated carbon filter and reverse osmosis membrane promptly. Deep clean the heating element and piping system monthly with a dedicated descaling agent. Afterward, rinse repeatedly with ultrapure water to eliminate chemical residue.

Regular maintenance of mechanical components is essential. Door seals should be coated with medical silicone oil monthly to maintain elasticity. Instrument basket rails should be regularly cleaned and lubricated with food-grade grease. Critical components such as temperature sensors and conductivity probes require professional calibration every quarter to ensure accurate and reliable parameter measurements. Establish a complete maintenance file, recording in detail the content of each maintenance, troubleshooting, and component replacement. Operators should receive professional training and master the correct loading methods and daily maintenance skills. Before long-term deactivation, all water systems must be thoroughly drained and properly treated with anti-mildew and anti-rust treatments. When reactivated, a no-load performance test must be performed. Through standardized preventive maintenance, not only can the service life of the equipment be extended by 3-5 years, but the quality stability of each cleaning operation can also be ensured, providing a solid guarantee for the accuracy of laboratory work. In case of complex faults, professional maintenance personnel should be contacted to avoid secondary damage caused by unauthorized disassembly.

English

English Español

Español Français

Français

CONTACT US

CONTACT US