Medical Laboratory Equipment And Consumables Manufacturers

information to be updated

With a building area of 20,310 square metres, the company has a class 100,000 purified production workshop, a class 10,000 microbiology testing room, a local class 100 physical and chemical laboratory, and a standardised storage system for raw materials and finished products.

Since the initial batch of products were launched in 2013, Eray has continuously enriched its product categories. Our products have covered protective masks, nursing consumables, sensory control consumables, surgical instruments, providing safe, efficient and environmentally friendly disposable medical solutions for medical institutions worldwide.

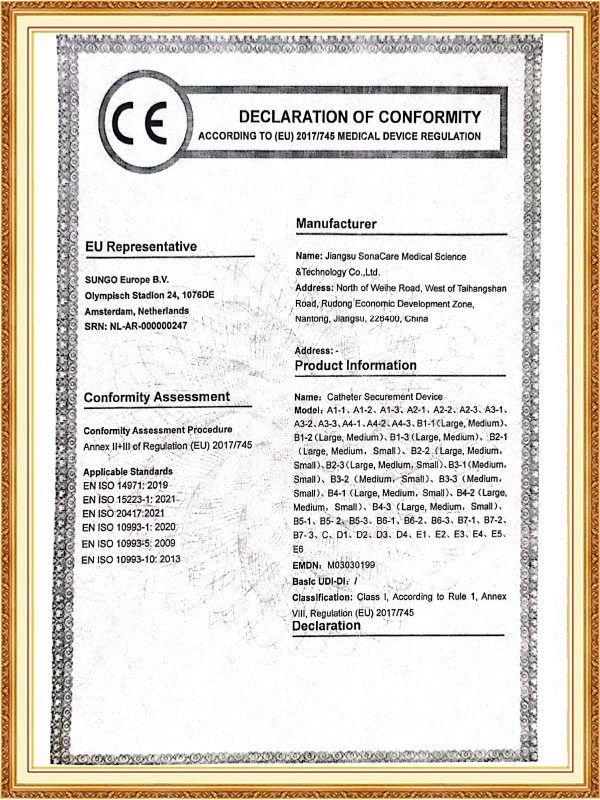

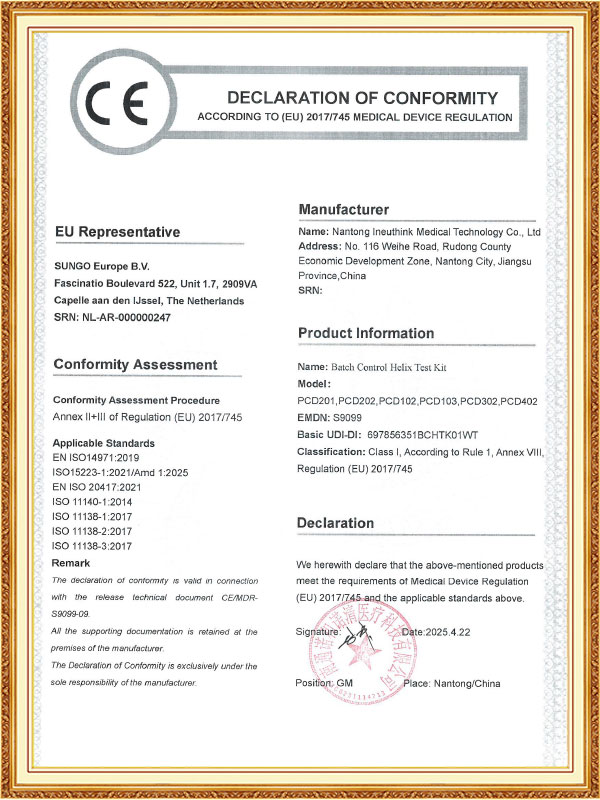

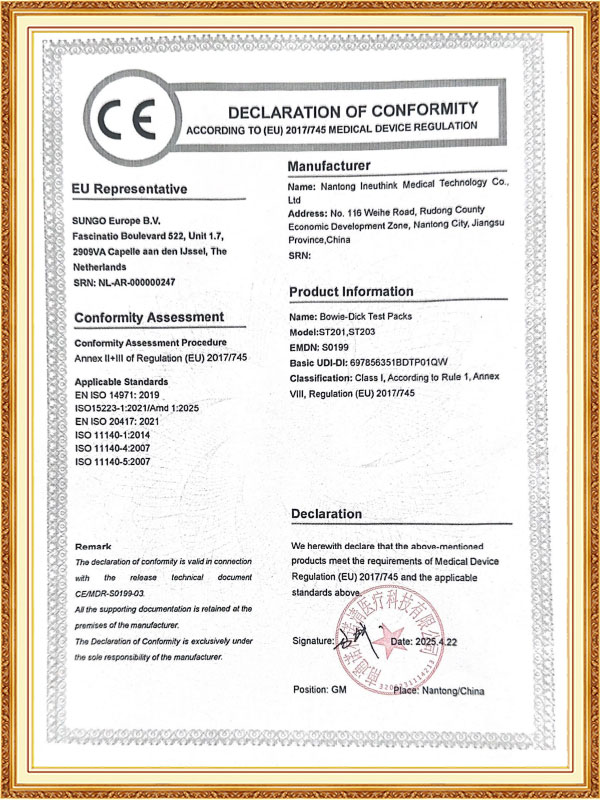

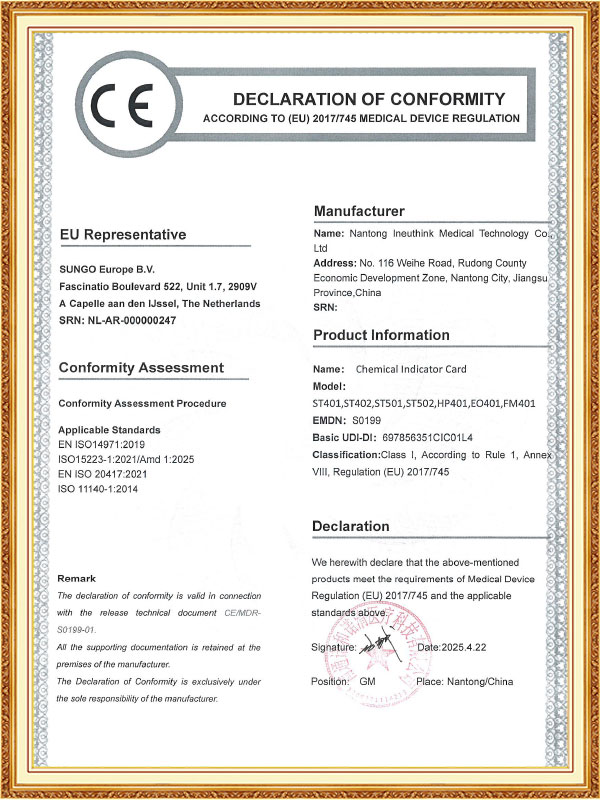

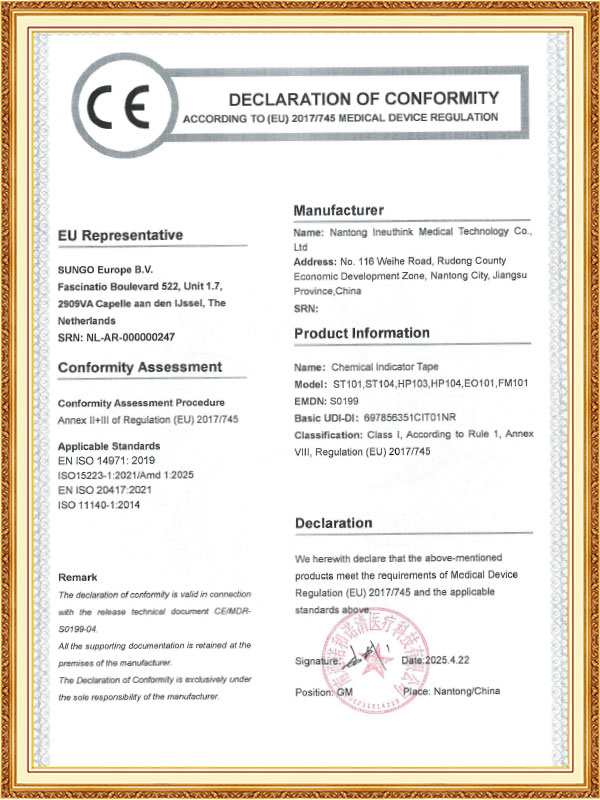

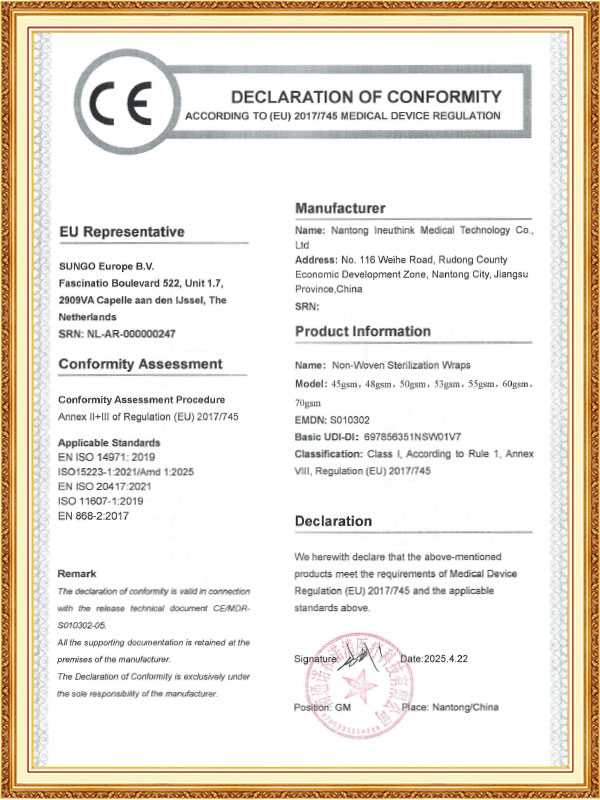

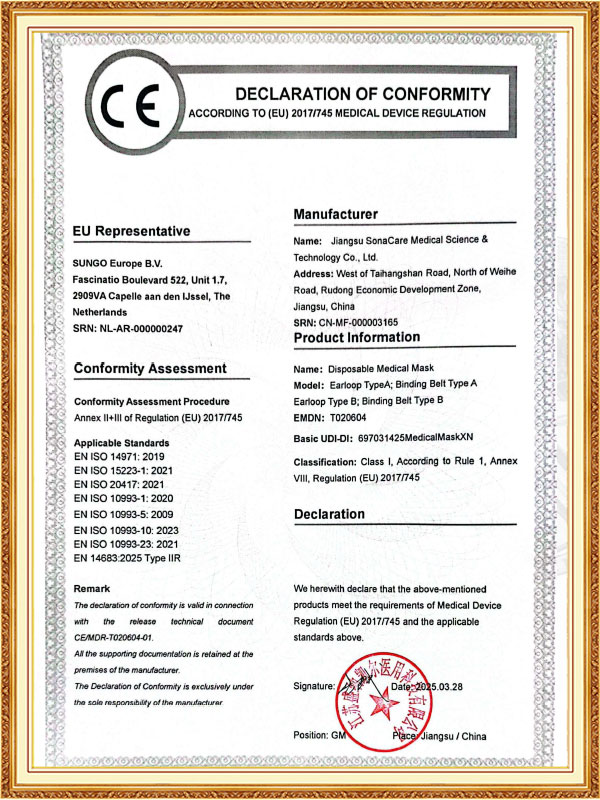

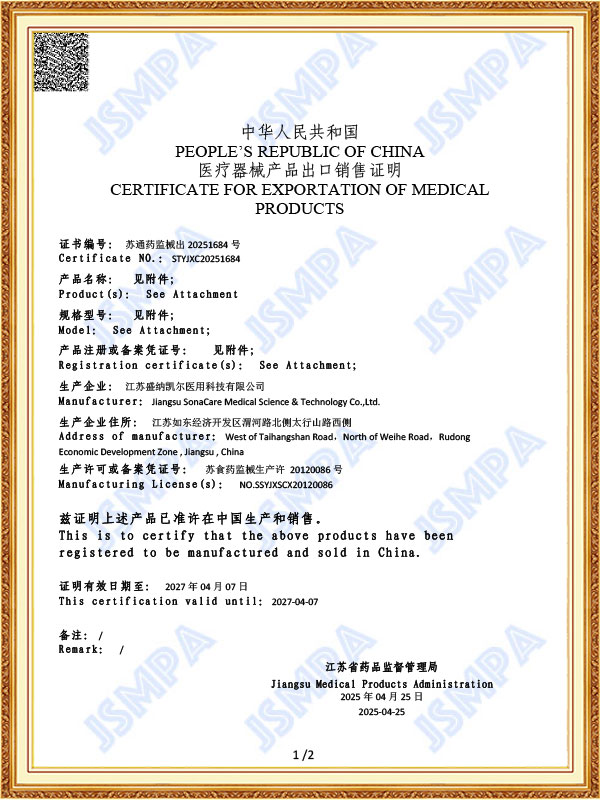

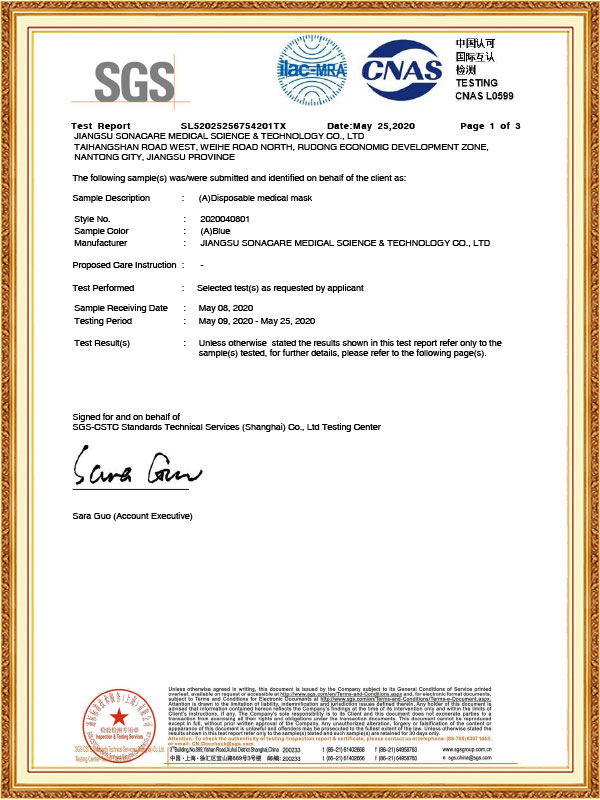

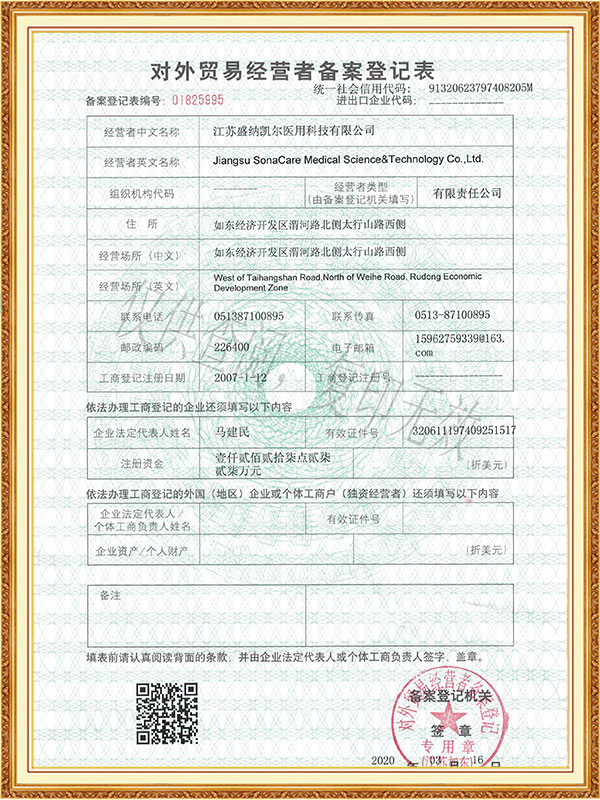

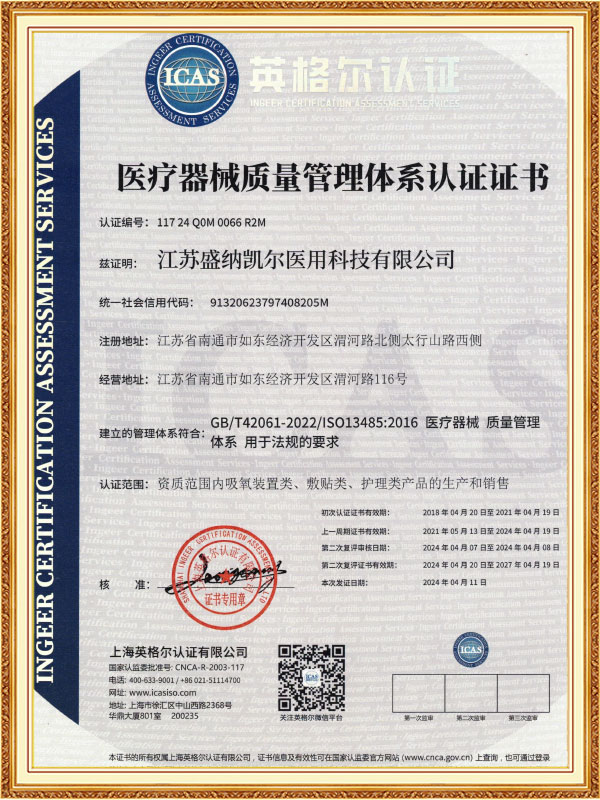

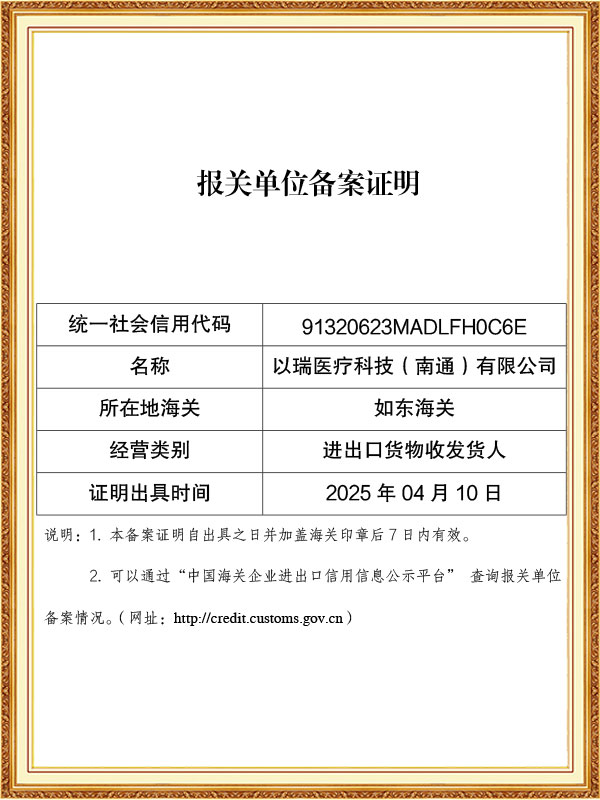

As a professional OEM Medical Laboratory Equipment Manufacturers and ODM Medical Laboratory Consumables Factory, The company has passed ISO 13485 and other quality system certifications, and some of its products have obtained CE certification and FDA filing permits, and has established long-term cooperative relationships with many domestic and foreign medical institutions and distributors.

-

Feb 27. 2026

Can Optical Trocars Reduce the Risk of Organ Injury?Optical Trocars Significantly Reduce Organ Injury Risk Yes, optical trocars can significantly reduce the risk of organ injury during laparoscopic surgery by allowing surgeons to visualize tissue layers in real time as the instrument passes through the abdominal wall. Unlike blin...

Read More -

Feb 20. 2026

What is an Optical Trocar and Why is it Essential in Medical Procedures?What is an Optical Trocar and Why is it Essential in Medical Procedures? An optical trocar is a specialized surgical instrument used primarily in minimally invasive procedures. It combines the functions of a trocar and a visual scope, allowing surgeons to create an access point ...

Read More -

Feb 13. 2026

What Are the Common Problems With Medical Trocars and How to Avoid Them?What Are the Most Common Problems With Medical Trocars? The most common problems with medical trocars include insertion injuries, gas leakage, dull blades, instability, and contamination risks. These issues can compromise surgical safety, increase operating time, and raise posto...

Read More

In the laboratory and pharmaceutical fields, the cleanliness and sterility of instruments and equipment are directly related to the accuracy of experimental data and the safety of drug production. Leveraging years of expertise, Eray MedTech has launched a series of laboratory glassware washers and pharmaceutical sterilizers, providing comprehensive cleanliness solutions for the scientific research and pharmaceutical industries.

Laboratory Glassware Washer: Intelligent Cleanliness, Precision and Efficiency

The Eray MedTech laboratory glassware washer features an innovative design concept and integrates multiple patented technologies. Equipped with a multi-angle rotating spray system and a custom-designed washing basket, it ensures thorough cleaning of every corner of all types of custom-shaped glassware. An intelligent temperature control system automatically adjusts the water temperature to suit specific cleaning needs, reaching up to 93°C to effectively remove stubborn stains.

This washer is equipped with an advanced filtration system featuring a three-stage filtration design that effectively captures particles larger than 0.45μm. An innovative drying system uses efficient hot air circulation to ensure rapid, residue-free drying of glassware. The user-friendly interface supports multiple preset programs, allowing users to select the optimal cleaning solution for different glassware materials, significantly improving laboratory efficiency.

Pharmaceutical Sterilizers: Strict Standards, Safe and Reliable

Eray MedTech pharmaceutical sterilizers adhere strictly to GMP certification requirements and utilize advanced pulsating vacuum sterilization technology to ensure sterilization results achieve a sterility assurance level of 10^-6. Equipped with an intelligent control system, the equipment monitors and records key parameters such as temperature and pressure in real time, ensuring traceability and full compliance with FDA 21 CFR Part 11.

The sterilization chamber is constructed of high-quality 316L stainless steel, offering excellent corrosion resistance. Innovative steam penetration technology ensures that the sterilization medium fully penetrates the interior of the device, achieving optimal sterilization results even for complex instruments. Safety interlocks and multiple protection systems provide comprehensive operator safety.

Laboratory glassware washers and pharmaceutical sterilizers require a scientific and standardized daily management process. For glassware washers, drain all accumulated water and wipe the interior after each run. Regularly check the spray arm for smooth rotation and use a dedicated descaling agent monthly to remove scale buildup. Ensure water quality meets requirements, with conductivity below 15 μS/cm. Remove the cleaning basket weekly and clean the mesh with a soft brush to prevent clogging that could affect cleaning performance. Pharmaceutical sterilizer maintenance focuses on regular calibration of temperature and pressure sensors, quarterly verification of sterilization effectiveness using biological indicators, monthly application of silicone oil to maintain elasticity of the door seals, and weekly cleaning of the sterilization chamber interior and drain filter. For steam sterilizers, drain the boiler water after each daily run, and regularly test steam quality to ensure it is free of excessive impurities. Both washers and sterilizers should maintain comprehensive operating records, including run parameters, maintenance details, and troubleshooting. Professionals should perform a comprehensive maintenance every six months, inspecting the electrical system, piping connections, and mechanical components for wear. The key is to strictly follow the equipment manual to select the appropriate cleaning procedures and sterilization cycles to avoid overloading and premature aging of the equipment. All maintenance operations should be recorded in detail to form a traceable quality management file to ensure that the equipment is always in optimal working condition.

English

English Español

Español Français

Français

CONTACT US

CONTACT US