With a building area of 20,310 square metres, the company has a class 100,000 purified production workshop, a class 10,000 microbiology testing room, a local class 100 physical and chemical laboratory, and a standardised storage system for raw materials and finished products.

Since the initial batch of products were launched in 2013, Eray has continuously enriched its product categories. Our products have covered protective masks, nursing consumables, sensory control consumables, surgical instruments, providing safe, efficient and environmentally friendly disposable medical solutions for medical institutions worldwide.

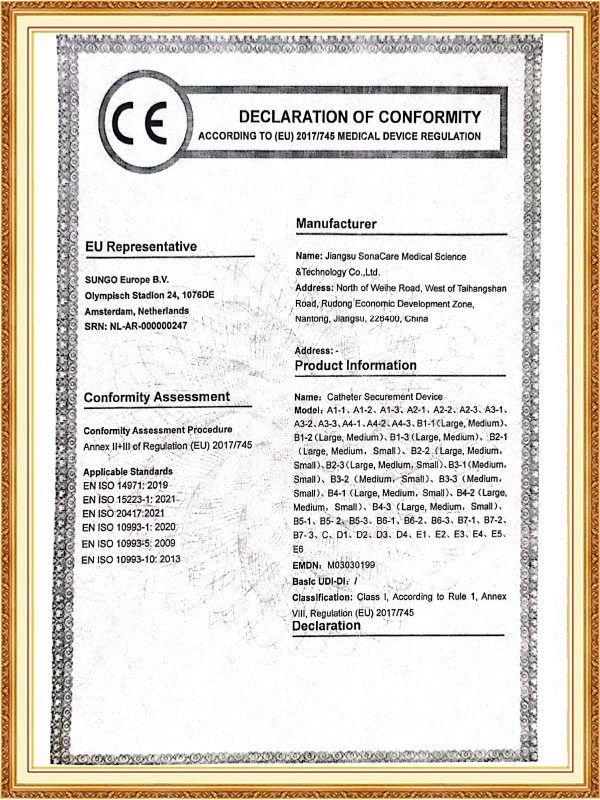

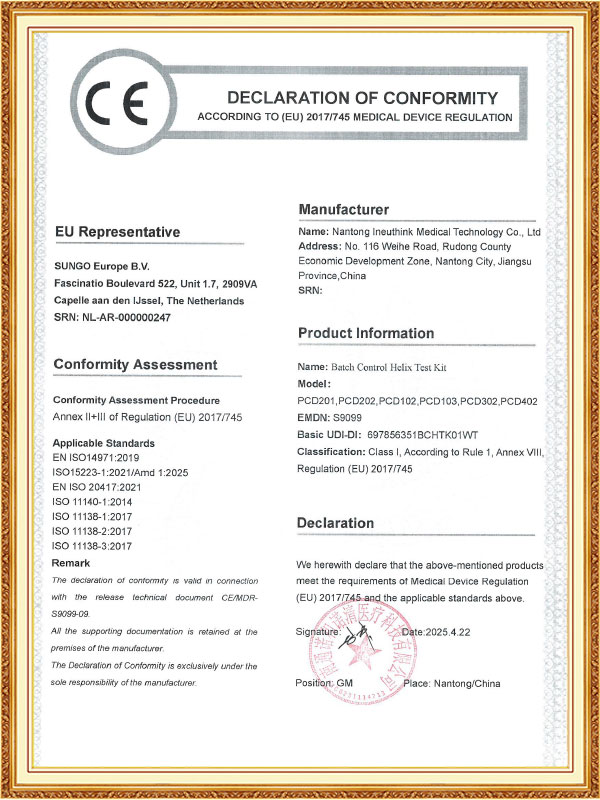

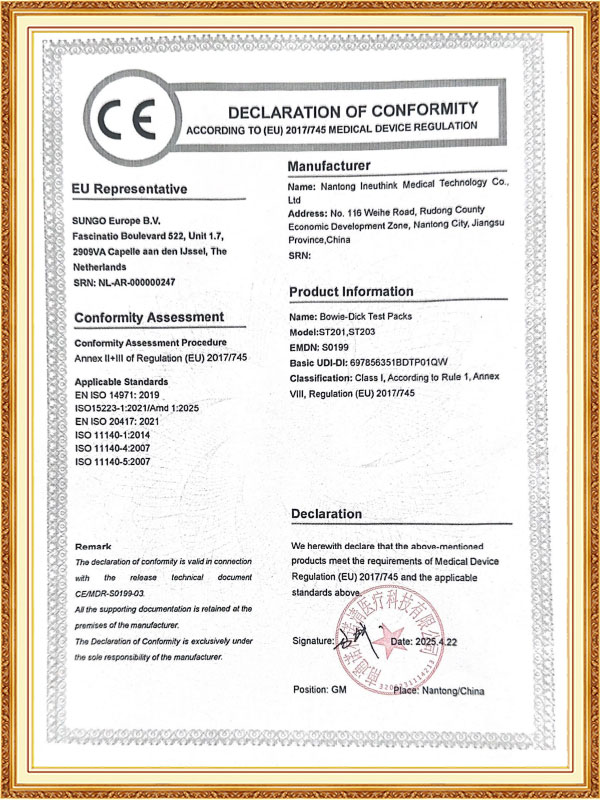

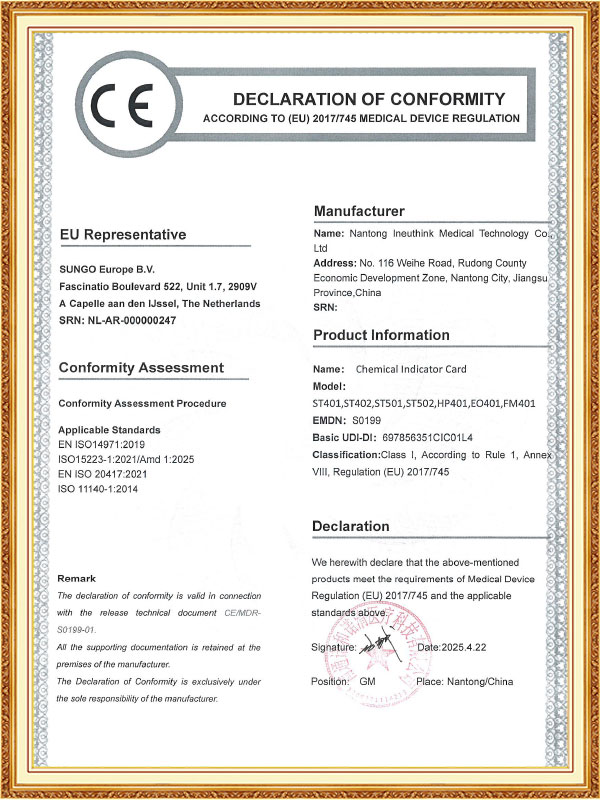

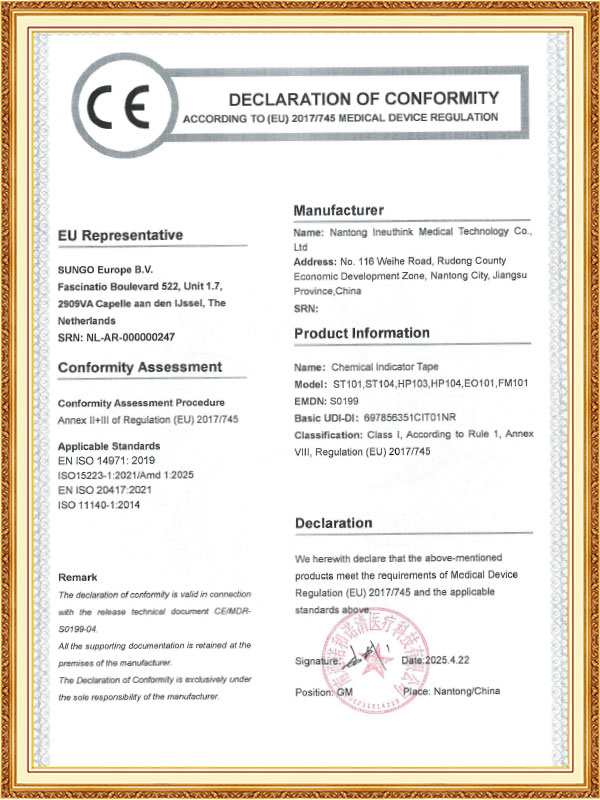

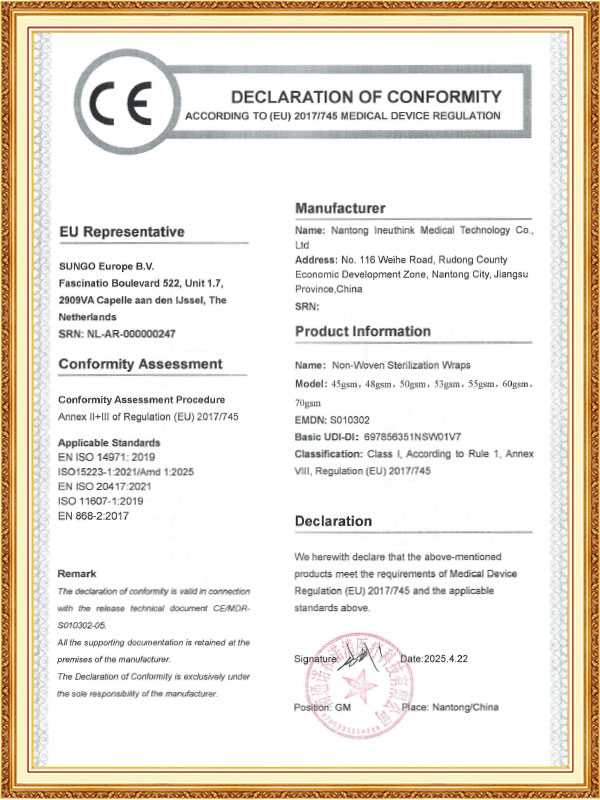

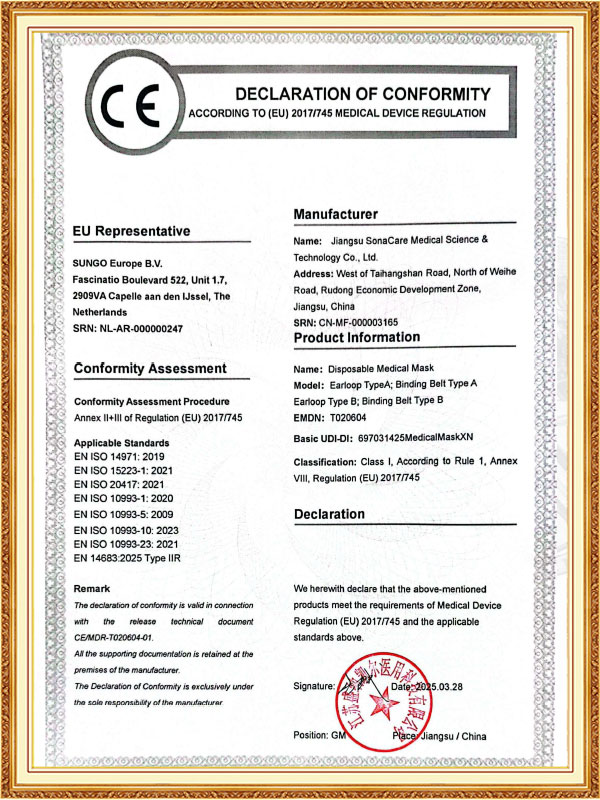

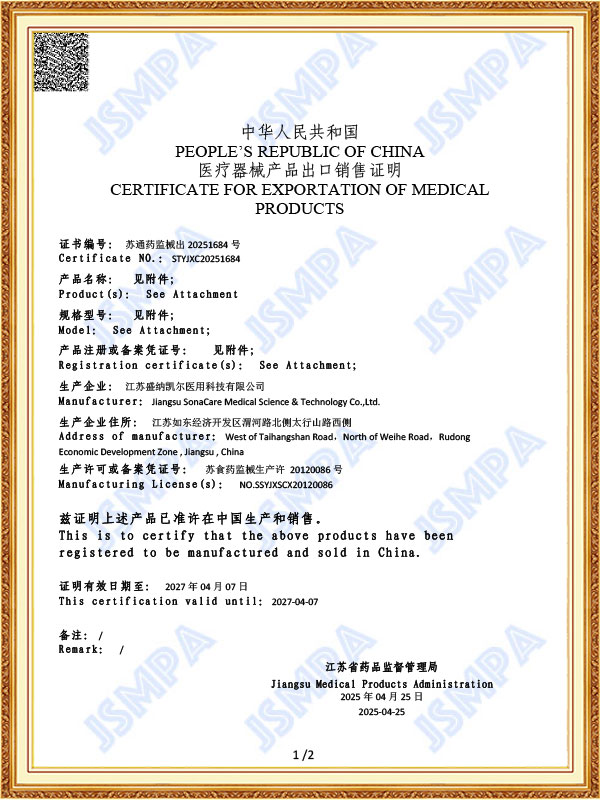

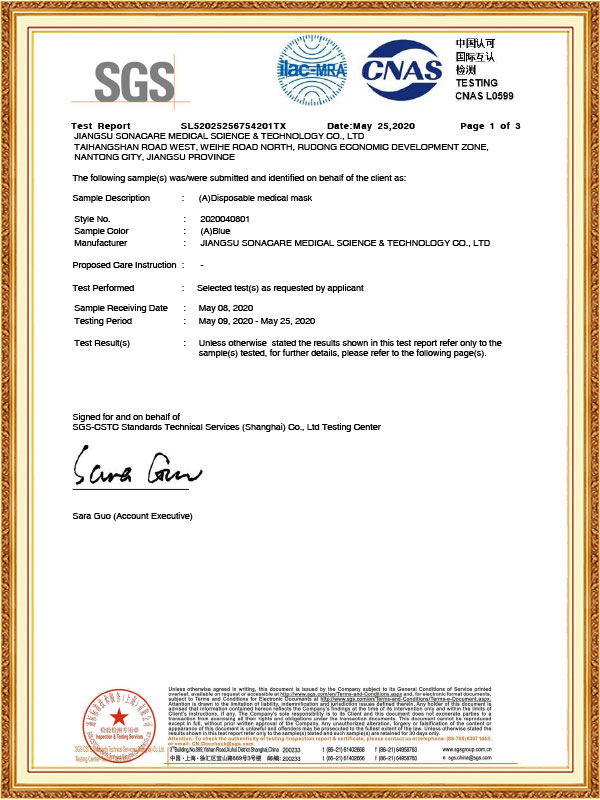

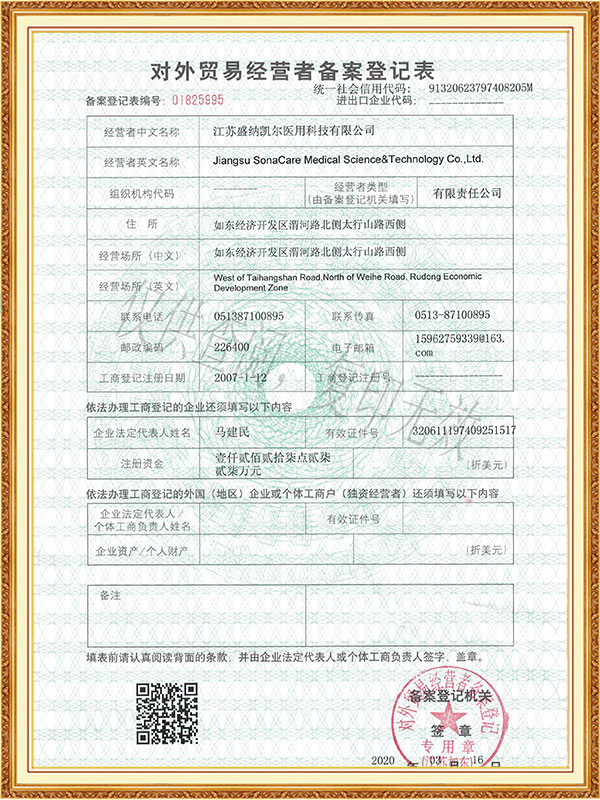

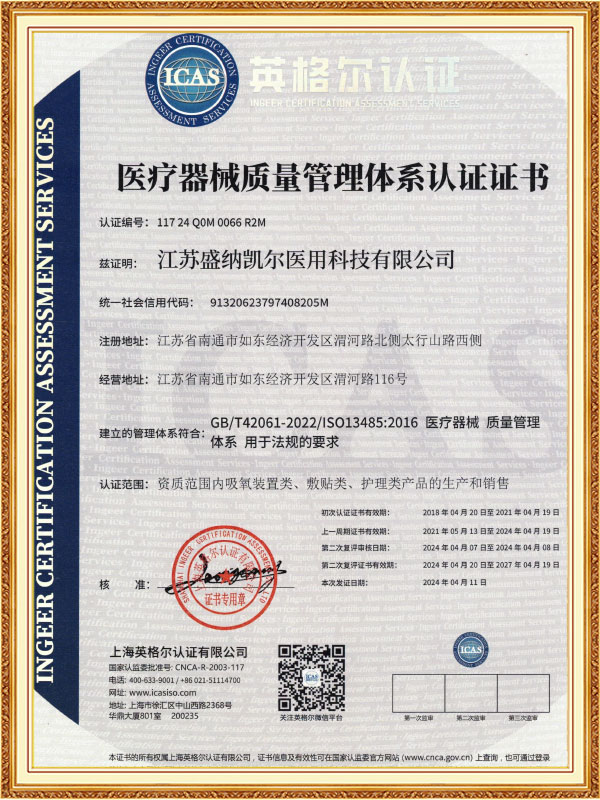

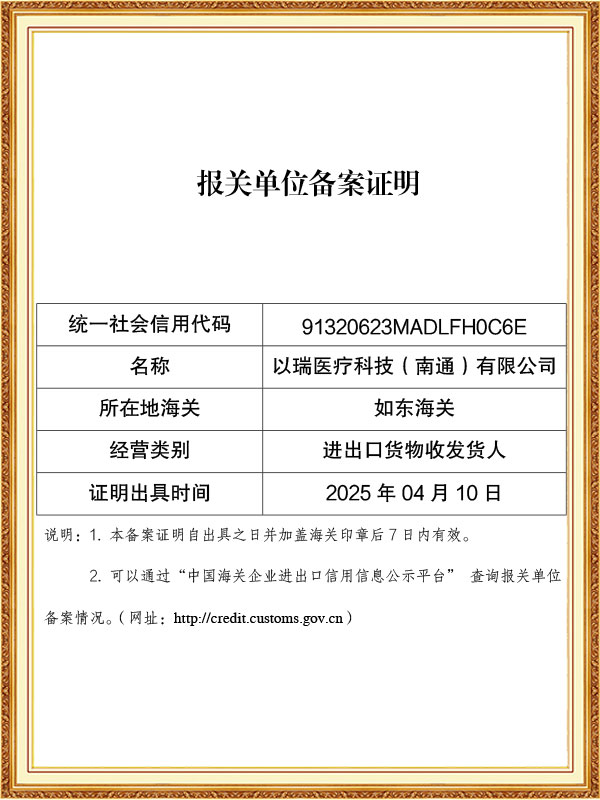

As a professional OEM Instrument Washer Suppliers and ODM Instrument Washer Disinfectors Factory, The company has passed ISO 13485 and other quality system certifications, and some of its products have obtained CE certification and FDA filing permits, and has established long-term cooperative relationships with many domestic and foreign medical institutions and distributors.

-

Feb 27. 2026

Can Optical Trocars Reduce the Risk of Organ Injury?Optical Trocars Significantly Reduce Organ Injury Risk Yes, optical trocars can significantly reduce the risk of organ injury during laparoscopic surgery by allowing surgeons to visualize tissue layers in real time as the instrument passes through the abdominal wall. Unlike blin...

Read More -

Feb 20. 2026

What is an Optical Trocar and Why is it Essential in Medical Procedures?What is an Optical Trocar and Why is it Essential in Medical Procedures? An optical trocar is a specialized surgical instrument used primarily in minimally invasive procedures. It combines the functions of a trocar and a visual scope, allowing surgeons to create an access point ...

Read More -

Feb 13. 2026

What Are the Common Problems With Medical Trocars and How to Avoid Them?What Are the Most Common Problems With Medical Trocars? The most common problems with medical trocars include insertion injuries, gas leakage, dull blades, instability, and contamination risks. These issues can compromise surgical safety, increase operating time, and raise posto...

Read More

Instrument washer-disinfectors utilize a multi-stage programmable control principle, achieving cleaning and disinfection through the synergistic effects of physical and chemical processes. The equipment begins with a pre-rinse, using warm water to rinse visible contaminants from the instrument surface. This is followed by a main rinse, where hot water (typically 45-60°C) containing an enzyme detergent is sprayed to break down organic residues such as proteins. A high-temperature rinse phase uses purified water to remove detergent residue. Finally, the disinfection phase inactivates microorganisms by maintaining the water temperature above 90°C or using a chemical disinfectant. Advanced models also feature a drying program that uses highly filtered hot air to quickly dry instruments.

Modern instrument washer-disinfectors have several outstanding features: an intelligent control system that can store hundreds of cleaning programs and allows for user-interface interaction via a touchscreen; a multi-directional rotating spray arm ensures thorough cleaning; an integrated water treatment system provides purified water that meets standards; a thermal monitoring system that monitors the cleaning temperature of each area in real time; and an environmentally friendly design that ensures efficient use of water and energy. Some high-end models also incorporate quality control systems such as turbidity monitoring and ATP bioluminescence detection to objectively assess cleaning results.

This equipment is widely used for processing medical supplies such as surgical instruments, anesthesia equipment, and respiratory tubes. Its standardized operation not only significantly improves cleaning efficiency but also ensures compliance with cleaning quality standards required by standards such as WS310-2016. Compared to manual cleaning, automated processing eliminates operational variability, better protects device integrity, and reduces worker exposure risks. During epidemic prevention and control efforts, large-capacity washer-disinfectors are able to process large batches of devices more quickly, demonstrating exceptional emergency value.

With the advancement of medical technology, the next generation of washer-disinfectors is evolving towards smarter and more precise features. These innovations will continue to improve the safety and efficiency of medical device processing, providing stronger guarantees for patient safety and healthcare quality.

Maintaining an instrument washer-disinfector is a systematic task, requiring a scientific and standardized daily management process. After each use, drain the chamber promptly. Thoroughly wipe key areas such as the interior walls, door seals, and spray arms with a neutral detergent, paying particular attention to removing residual stains and scale. The spray system is a key maintenance priority. Regularly check the spray holes for blockage and ensure smooth rotation. Clean the filters at the water inlet and outlet to maintain unimpeded water flow. Deep maintenance should be performed monthly. Use a dedicated descaling agent to thoroughly clean areas prone to scale accumulation, such as heating elements and piping. Afterwards, rinse repeatedly with pure water to eliminate chemical residue. Mechanical component maintenance is equally important. Door seals should be coated monthly with medical silicone oil to prevent aging. Moving parts, such as slide rails and hinges, should be regularly inspected and lubricated with food-grade grease. A comprehensive equipment inspection, including leak testing, sensor calibration, and biological monitoring verification, is required to ensure that key parameters such as temperature and pressure are accurate and reliable, and that sterilization efficacy meets the standard requirement of ≥99.9%. Before the equipment is out of use for a long time, all water tanks and pipes must be drained and dust-proofed. When it is reactivated, a no-load test must be performed first. It is crucial to establish a complete maintenance file, and detailed records must be kept of each cleaning, calibration, and repair. At the same time, operators must receive regular professional training to enable them to master the correct usage methods and basic troubleshooting skills. Troubleshooting skills for complex problems. When encountering complex problems, professional maintenance personnel should be contacted in a timely manner, and self-disassembly should be avoided. Through standardized maintenance management, not only can the service life of the equipment be extended by 3-5 years, but it can also ensure the continuous provision of safe and reliable cleaning and disinfection services, providing a solid guarantee for medical quality and safety.

English

English Español

Español Français

Français

CONTACT US

CONTACT US